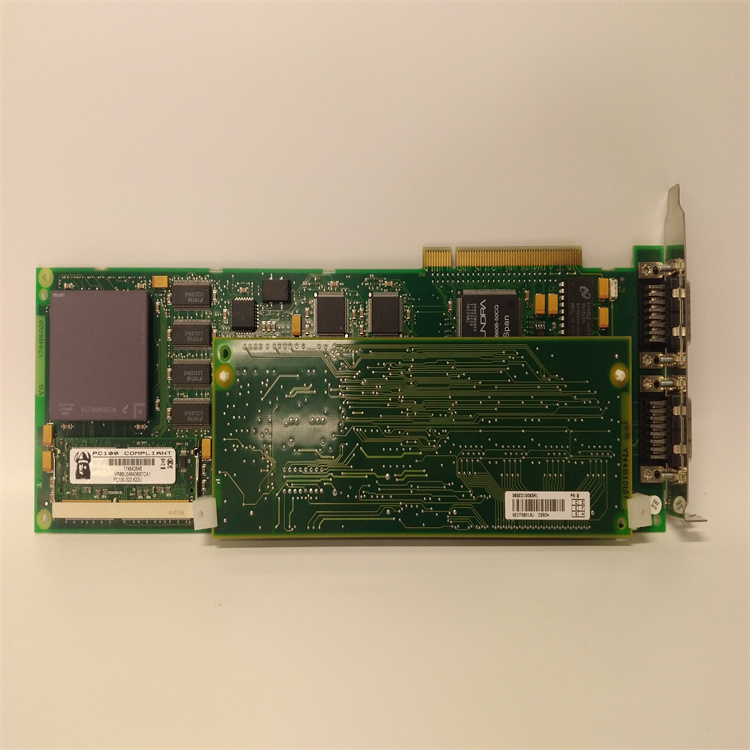

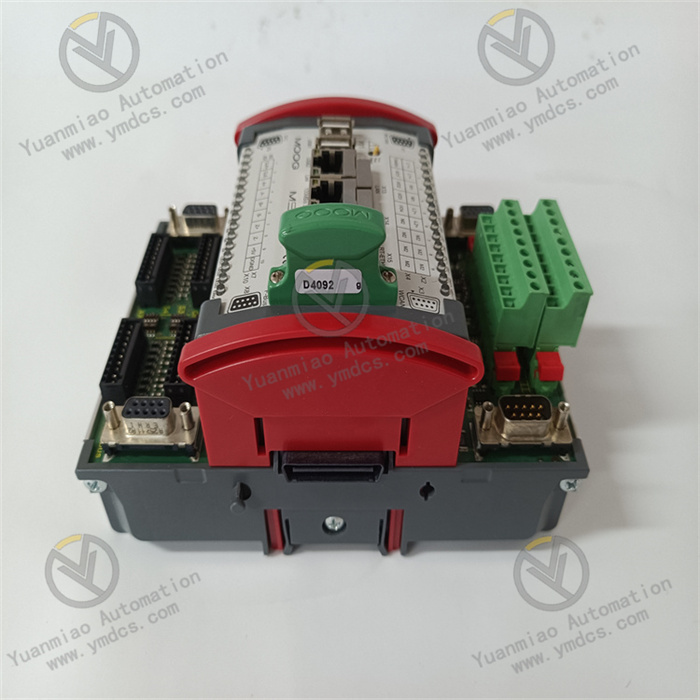

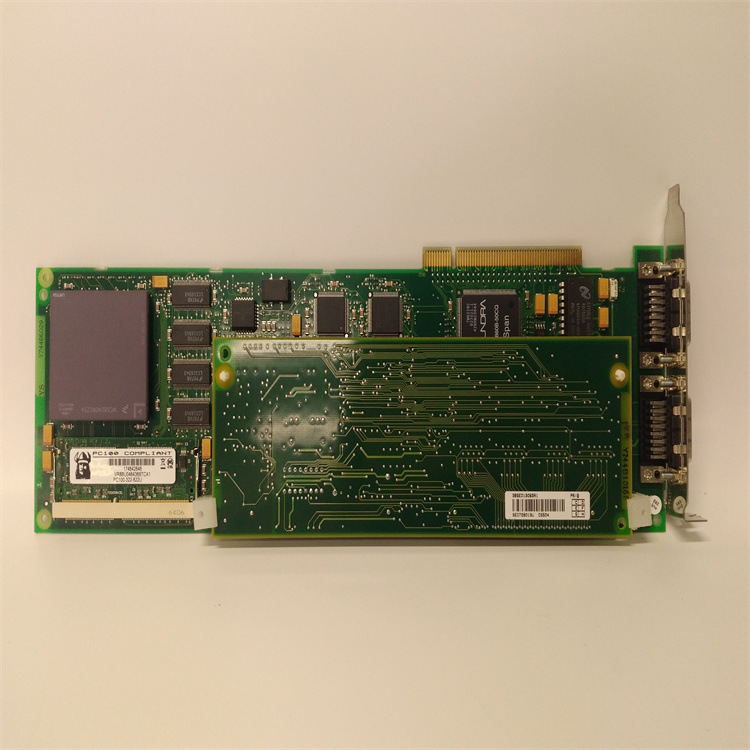

Description

Main Features High-performance processing capability: It has powerful computing and data processing capabilities, and can quickly execute complex control algorithms and logical operations, process a large amount of process data in real time, and meet the requirements for control accuracy and response speed in industrial production. Multiple communication interfaces: It is usually equipped with a rich variety of communication interfaces, such as Ethernet interfaces, serial ports, etc., which can conveniently carry out data communication and interaction with other devices (such as sensors, actuators, upper computers, etc.), and realize the integration and expansion of the system. High reliability: Adopting industrial-grade design and manufacturing standards, it has good anti-interference ability and stability, and can operate reliably in harsh industrial environments (such as high temperature, high humidity, strong electromagnetic interference, etc.), reducing system downtime and maintenance costs. Flexible programming and configuration: It supports programming in multiple programming languages (such as ladder diagram, structured text, etc.), which is convenient for engineers to develop and configure programs according to specific control requirements. At the same time, the parameters of the controller can be set and adjusted through the corresponding software tools to adapt to different production processes and application scenarios. Redundancy function: Some models may have redundancy functions, such as power redundancy, communication redundancy, etc. When a certain module fails, the redundant module can automatically take over the work to ensure the continuous operation of the system and improve the reliability and availability of the system.

Technical Parameters Processor performance: Usually, high-performance microprocessors are used, and the specific processor models and performance parameters may vary depending on the product version. Memory capacity: It has a certain amount of memory space for storing programs and data. For example, it may be equipped with dozens of megabytes to several hundred megabytes of memory to meet the control program and data storage requirements of different scales. Communication rate: The communication rate of the Ethernet interface can generally reach 10/100Mbps or even higher, and the serial port communication rate can be set according to actual needs. Operating voltage: Generally, it is powered by 24V DC, and it may also support other voltage ranges. Specifically, it shall be subject to the product specifications. Operating temperature range: It can usually work normally within a temperature range of 0°C to 55°C or a wider temperature range to adapt to different industrial environments. Application Fields Process industry: It is widely used in process industry fields such as chemical industry, petroleum, natural gas, power, and metallurgy, and is used to control various parameters in the production process, such as temperature, pressure, flow rate, liquid level, etc., to realize the automatic control and optimization of the production process. Manufacturing industry: In the automated production lines of the manufacturing industry, it can control and monitor production equipment, coordinate the actions of various devices, and improve production efficiency and product quality. For example, in industries such as automobile manufacturing and electronics manufacturing, it is used to control robots, conveying equipment, processing equipment, etc. Energy management: In energy production and distribution systems, such as power plants, substations, smart grids, etc., it can monitor and control the production, transmission, and consumption of energy to achieve efficient utilization and optimized management of energy. Building automation: It is used in the building automation systems of intelligent buildings to centrally control and manage equipment such as air conditioners, lighting, elevators, and security systems in buildings, improving the comfort and energy efficiency of buildings.

Its programming and configuration methods: Programming 1. Selection of programming languages The ABB Symphony Plus system supports multiple programming languages, mainly following the IEC 61131 - 3 standard, including: Ladder Diagram (LD): Similar to the traditional relay control circuit, it represents logical relationships in a graphical way, is easy to understand, and is suitable for beginners and logical control. Function Block Diagram (FBD): Uses function blocks to represent various functions, and the signal flow is represented by connecting lines. It is often used for complex analog quantity control and algorithm implementation. Structured Text (ST): Similar to high-level programming languages, it writes programs in text form and is suitable for implementing complex mathematical operations and algorithms. Sequential Function Chart (SFC): It is used to describe the sequential control process and represents the program flow in the way of steps and transitions. It is often used for sequential control tasks. 2. Programming environment Generally, the Symphony Plus engineering toolkit provided by ABB, such as Automation Builder, is used. The operation steps are as follows: Create a project: Open the Automation Builder software, create a new project, and set the basic information of the project according to actual needs, such as the project name, save path, etc. Add a controller: Add the PU516A 3BSE032402R1 controller to the project and specify its model and related parameters. Define variables: According to the control requirements, define input and output variables (such as sensor signals, actuator control signals), intermediate variables, constants, etc. The variable types can be Boolean, integer, floating-point, etc. Write a program: Select an appropriate programming language and write the control program in the corresponding programming window. For example, if using ladder diagram programming, various logical elements (such as normally open contacts, normally closed contacts, coils, etc.) can be dragged and dropped from the tool library to the programming area and connected and set. Compile and debug: After writing, compile the program to check for syntax errors. If there are errors, modify them according to the compilation prompts. After the compilation passes, the program can be downloaded to the controller for debugging, observe the operation of the system, and optimize and adjust the program.

Configuration 1. Hardware configuration Physical connection: Install the PU516A 3BSE032402R1 module correctly in the control cabinet, and connect the power supply, communication cables, input and output signal cables, etc. Ensure that the cables are firmly connected to avoid looseness and poor contact. Module parameter setting: Through the Automation Builder software, set the hardware parameters of the module, such as the module address, communication rate, input and output types, etc. Different hardware configurations may require different parameter settings, which need to be adjusted according to the actual situation. 2. Communication configuration Network topology setting: Determine the network topology structure of the control system, such as Ethernet, fieldbus, etc. Set the network parameters of the controller in Automation Builder, including the IP address, subnet mask, gateway, etc., to ensure that the controller can communicate normally with other devices. Communication protocol configuration: Configure the corresponding communication protocol according to the types of connected devices and communication requirements. For example, if communicating with other ABB devices, the ABB's own communication protocol may be used; if communicating with third-party devices, standard protocols such as Modbus and Profibus may be required. Set the parameters of the communication protocol in the software, such as baud rate, data bits, stop bits, parity bits, etc. 3. Input and output configuration Channel definition: Define the input and output channels in Automation Builder and associate the physical channels with the variables in the program. For example, associate a certain analog input channel with a floating-point variable in the program to read the signal value of this channel in the program. Range setting: For analog input and output channels, the range needs to be set. According to the ranges of the actual sensors and actuators, set the corresponding upper and lower limits in the software to ensure the accuracy of the collected and output data. 4. System configuration Redundancy configuration (if supported): If the system supports redundancy functions, such as power redundancy, communication redundancy, etc., perform the corresponding redundancy configuration in the software. Set the parameters and working modes of the redundant modules to ensure that when the main module fails, the redundant module can automatically take over the work. Security configuration: Set the security parameters of the system, such as password protection, access rights control, etc., to ensure the security and reliability of the system. At the same time, configure the fault diagnosis and alarm functions to be able to send out alarm signals in a timely manner when the system is abnormal.

Main Products:

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage