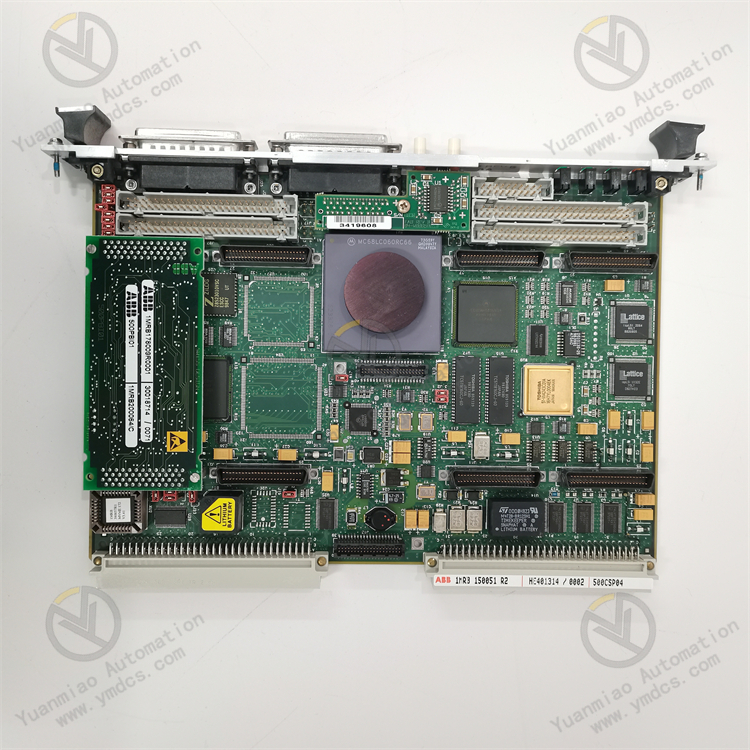

Description

Praxis 98.6.030.702

I. Overview

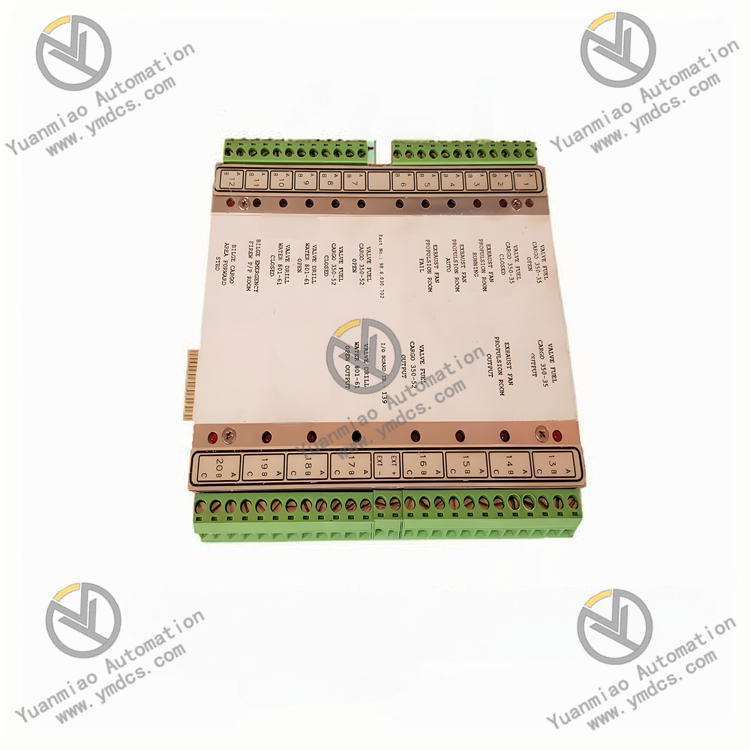

Praxis 98.6.030.702 is a DIN I/O module that plays an important role in the field of industrial automation. It is specifically designed to meet the diverse data input and output control needs in complex industrial environments. With its precise data processing capability and reliable operating performance, it serves as a key bridge connecting on-site equipment and control centers in various automated control systems. It is widely used in scenarios such as shipbuilding, industrial production lines, and smart factories, providing strong support for the stable operation and efficient control of equipment.

Praxis 98.6.030.702 is a DIN I/O module that plays an important role in the field of industrial automation. It is specifically designed to meet the diverse data input and output control needs in complex industrial environments. With its precise data processing capability and reliable operating performance, it serves as a key bridge connecting on-site equipment and control centers in various automated control systems. It is widely used in scenarios such as shipbuilding, industrial production lines, and smart factories, providing strong support for the stable operation and efficient control of equipment.

For example, in a ship automation system, this module can connect numerous sensors (such as liquid level sensors and temperature sensors) and actuators (such as valve actuators and motor controllers) on the ship. It accurately transmits real-time data collected by the sensors to the ship's control system, and at the same time, precisely conveys instructions from the control system to the actuators, realizing the automatic control of the ship's power system, cabin environment system, etc., and ensuring the safety and stability of the ship's navigation.

II. Technical Parameters

Input voltage: Supports 24V DC power supply, adapting to the power configuration of most industrial automation systems to ensure stable power supply.

Input signal type: The digital input channels can accept various signal types such as dry contacts and NPN/PNP proximity switches, with strong compatibility, which can meet the connection needs of different on-site equipment.

Output load capacity: The digital output channels have strong load driving capability, and can directly drive loads such as small relays and indicator lights. The output current of each channel can generally reach 0.5A, meeting the power requirements of common industrial control scenarios.

Operating temperature range: The operating temperature range is -20°C to +60°C, which can adapt to temperature changes in different industrial environments. It can operate stably whether in cold northern factories or hot southern workshops.

Protection level: The protection level reaches IP20, which can effectively prevent dust and foreign objects from entering the module, affecting its normal operation, and ensuring reliable operation in dusty industrial environments.

Input voltage: Supports 24V DC power supply, adapting to the power configuration of most industrial automation systems to ensure stable power supply.

Input signal type: The digital input channels can accept various signal types such as dry contacts and NPN/PNP proximity switches, with strong compatibility, which can meet the connection needs of different on-site equipment.

Output load capacity: The digital output channels have strong load driving capability, and can directly drive loads such as small relays and indicator lights. The output current of each channel can generally reach 0.5A, meeting the power requirements of common industrial control scenarios.

Operating temperature range: The operating temperature range is -20°C to +60°C, which can adapt to temperature changes in different industrial environments. It can operate stably whether in cold northern factories or hot southern workshops.

Protection level: The protection level reaches IP20, which can effectively prevent dust and foreign objects from entering the module, affecting its normal operation, and ensuring reliable operation in dusty industrial environments.

III. Functional Features

Rich I/O interface configuration: Equipped with 12 digital input channels and 8 digital output channels, it can connect multiple different types of digital signal devices at the same time. The digital input channels can quickly and accurately collect information such as the switch status and pulse signals of external equipment, such as the running/stopping status of equipment and the pressing/releasing signals of buttons; the digital output channels can drive external executive equipment to act according to the instructions of the control system, such as controlling the on/off of indicator lights and the attraction/release of relays, realizing remote control of equipment.

Highly reliable data transmission: Adopts advanced electrical isolation technology to effectively isolate input and output signals from internal circuits, enhancing the module's anti-interference ability and ensuring the accuracy and stability of data transmission in complex electromagnetic environments. Even in industrial sites with a large number of strong electromagnetic interference sources such as motors and frequency converters, it can transmit data reliably, avoiding signal loss or misjudgment, and ensuring stable operation of the system.

Convenient system integration: The module is designed in accordance with the standard DIN rail mounting method, with a small size and easy installation. It can be easily integrated into various control cabinets, saving installation space. At the same time, it supports multiple communication protocols, such as MODBUS, and can seamlessly connect with control systems such as PLCs and industrial computers of different brands, facilitating the construction of large-scale and complex automated control systems.

Rich I/O interface configuration: Equipped with 12 digital input channels and 8 digital output channels, it can connect multiple different types of digital signal devices at the same time. The digital input channels can quickly and accurately collect information such as the switch status and pulse signals of external equipment, such as the running/stopping status of equipment and the pressing/releasing signals of buttons; the digital output channels can drive external executive equipment to act according to the instructions of the control system, such as controlling the on/off of indicator lights and the attraction/release of relays, realizing remote control of equipment.

Highly reliable data transmission: Adopts advanced electrical isolation technology to effectively isolate input and output signals from internal circuits, enhancing the module's anti-interference ability and ensuring the accuracy and stability of data transmission in complex electromagnetic environments. Even in industrial sites with a large number of strong electromagnetic interference sources such as motors and frequency converters, it can transmit data reliably, avoiding signal loss or misjudgment, and ensuring stable operation of the system.

Convenient system integration: The module is designed in accordance with the standard DIN rail mounting method, with a small size and easy installation. It can be easily integrated into various control cabinets, saving installation space. At the same time, it supports multiple communication protocols, such as MODBUS, and can seamlessly connect with control systems such as PLCs and industrial computers of different brands, facilitating the construction of large-scale and complex automated control systems.

IV. Application Scenarios

Ship automation: As mentioned earlier, in the ship's automation control system, the Praxis 98.6.030.702 module is ubiquitous, from engine room equipment monitoring to deck machinery control. It helps realize functions such as ship navigation status monitoring, equipment fault diagnosis and alarm, improving the level of ship automation, reducing manual intervention, and improving ship operation efficiency.

Industrial production lines: In industrial production lines such as automobile manufacturing and electronic product assembly, this module can be used to real-time monitor the operating status of equipment at each station on the production line, such as the start-stop of conveyors and the action completion signals of robots, and control the equipment actions according to the production process requirements to ensure the smooth progress of the production process. Once a fault occurs in a certain link, the module can quickly feed back the fault information to the control system, triggering corresponding alarm and fault handling mechanisms, and reducing losses caused by production interruption.

Smart factories: In the smart factory environment, the Praxis 98.6.030.702 module, as a key equipment for underlying data collection and control, works in collaboration with upper-level manufacturing execution systems (MES) and enterprise resource planning systems (ERP). It collects operating data, energy consumption data, etc. of production equipment, providing accurate data support for factory production scheduling, equipment maintenance, energy management, etc., and helping to realize intelligent management and efficient production of the factory.

Ship automation: As mentioned earlier, in the ship's automation control system, the Praxis 98.6.030.702 module is ubiquitous, from engine room equipment monitoring to deck machinery control. It helps realize functions such as ship navigation status monitoring, equipment fault diagnosis and alarm, improving the level of ship automation, reducing manual intervention, and improving ship operation efficiency.

Industrial production lines: In industrial production lines such as automobile manufacturing and electronic product assembly, this module can be used to real-time monitor the operating status of equipment at each station on the production line, such as the start-stop of conveyors and the action completion signals of robots, and control the equipment actions according to the production process requirements to ensure the smooth progress of the production process. Once a fault occurs in a certain link, the module can quickly feed back the fault information to the control system, triggering corresponding alarm and fault handling mechanisms, and reducing losses caused by production interruption.

Smart factories: In the smart factory environment, the Praxis 98.6.030.702 module, as a key equipment for underlying data collection and control, works in collaboration with upper-level manufacturing execution systems (MES) and enterprise resource planning systems (ERP). It collects operating data, energy consumption data, etc. of production equipment, providing accurate data support for factory production scheduling, equipment maintenance, energy management, etc., and helping to realize intelligent management and efficient production of the factory.