Description

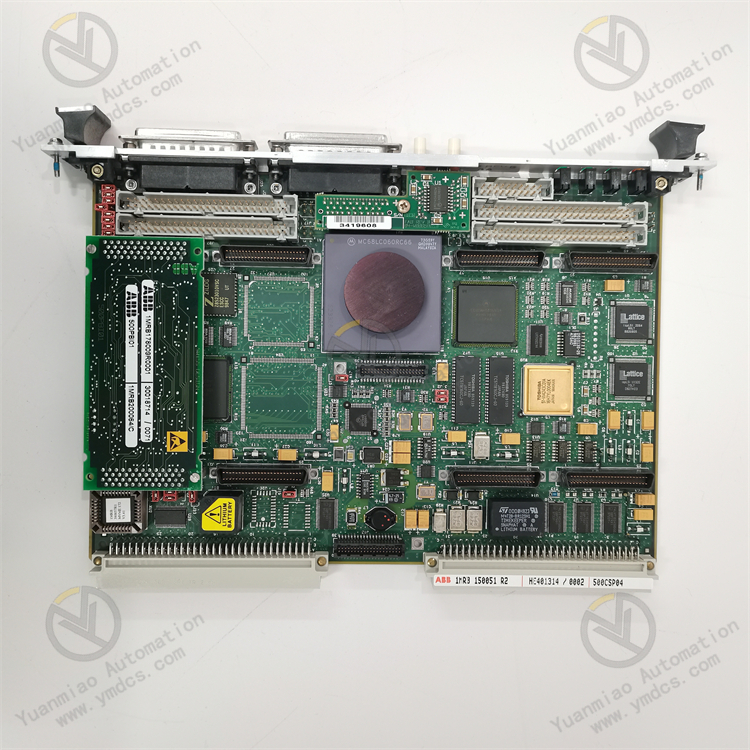

ABB 500PB101 1MRB178009R0001 1MRB200064/C

Functional Features

- Core Functions of the Controller

- Modular Design: Supports free combination of CPU modules, input/output (I/O) modules, communication modules, power modules, etc., adapting to automation needs of different scales.

- High-Performance Processing:

- Equipped with ARM or PowerPC processors, supporting high-speed logic operations, timers, counters, and other functions.

- Processing speed: Capable of executing tens of thousands of instructions per second (e.g., 0.1–1ms/kB program execution speed).

- Programming Language Compatibility: Supports IEC 61131-3 standard programming languages, such as Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), etc.

- Communication and Expansion Capabilities

- Built-in Communication Interfaces:

- May integrate Ethernet (supporting Modbus TCP, Profinet, etc.) and RS-485 (Modbus RTU) interfaces.

- If it is a communication module (e.g., PB101), it may support industrial bus protocols such as Profibus DP, EtherCAT, and CANopen.

- Expansion Capability:

- Can connect up to dozens of I/O modules, supporting digital (DI/DO), analog (AI/AO), high-speed counting, pulse output, and other functions.

- Reliability and Environmental Adaptability

- Industrial-Grade Design:

- Operating temperature: -20°C ~ +60°C (wide-temperature models may have a broader range).

- Protection level: IP20 (standard, suitable for installation in control cabinets); some modules support harsher environments (e.g., IP65 protection).

- Anti-Interference Capability: Complies with IEC 61000 electromagnetic compatibility standards, with excellent vibration and impact resistance, suitable for industrial field applications.

- Programming and Maintenance

- Software Tools: Uses ABB’s Control Builder M or AC500-ETH programming software, supporting online debugging, firmware upgrades, and fault diagnosis.

- Fault Diagnosis:

- Module status indicator lights (e.g., power, operation, fault, communication status) display real-time operating conditions.

- Supports remote monitoring and alarming (e.g., sending fault information to HMI or SCADA systems via Ethernet).

Technical Parameters

| Parameter Category | Parameter Value |

|---|---|

| Product Type | PLC controller module, communication module, or power module |

| CPU Type | ARM Cortex-M or PowerPC processor |

| Program Memory | Possibly 256 kB ~ 2 MB (depending on the model) |

| Data Memory | Possibly 128 kB ~ 1 MB |

| Communication Interfaces | 1×Ethernet (10/100Base-T), 1×RS-485 |

| Supported Protocols | Modbus TCP/RTU, Profinet, Profibus DP, etc. |

| I/O Expansion Capability | Up to 32 I/O modules (specific to the CPU model) |

| Power Supply Voltage | DC 24V or AC 85–264V (depending on the module type) |

| Power Consumption | Typical value <10W (module level) |

Working Principle

- Central Processing Unit (CPU)

- The core computing unit is responsible for executing user programs, processing logic control, and data operations.

- May adopt high-performance microprocessors (such as ARM or specialized industrial-grade chips) with real-time operating systems (RTOS) to ensure fast instruction response (nanosecond-level processing speed).

- Memory System

- Program Memory (ROM): Stores system firmware, boot programs, and user-written control logic programs (e.g., ladder diagrams, ST structured text, etc.).

- Data Memory (RAM): Temporarily stores input/output (I/O) statuses, intermediate variables, and real-time data (e.g., sensor readings).

- Input/Output (I/O) Modules

- Digital I/O: Connects to devices such as buttons, relays, and switches to receive ON/OFF signals (e.g., motor start/stop commands) or output control signals (e.g., solenoid valve drives).

- Analog I/O: Processes continuous signals (e.g., 4–20mA current, 0–10V voltage) for collecting sensor data (e.g., temperature, pressure, flow) or adjusting output parameters of frequency converters and servo systems.

- Special Function Modules (Optional): Supports high-speed counting, pulse output (e.g., servo motor control), communication expansion (e.g., Profibus, Ethernet/IP), etc.

- Communication Interfaces

- Serial communication: RS-232/485 (Modbus RTU).

- Industrial Ethernet: Profinet, Ethernet/IP, Modbus TCP.

- Fieldbus: Profibus DP, CANopen.

- Supports multiple industrial communication protocols, such as:

- Used to connect to host computers (SCADA systems), human-machine interfaces (HMI), other controllers, or smart devices for data interaction and remote monitoring.

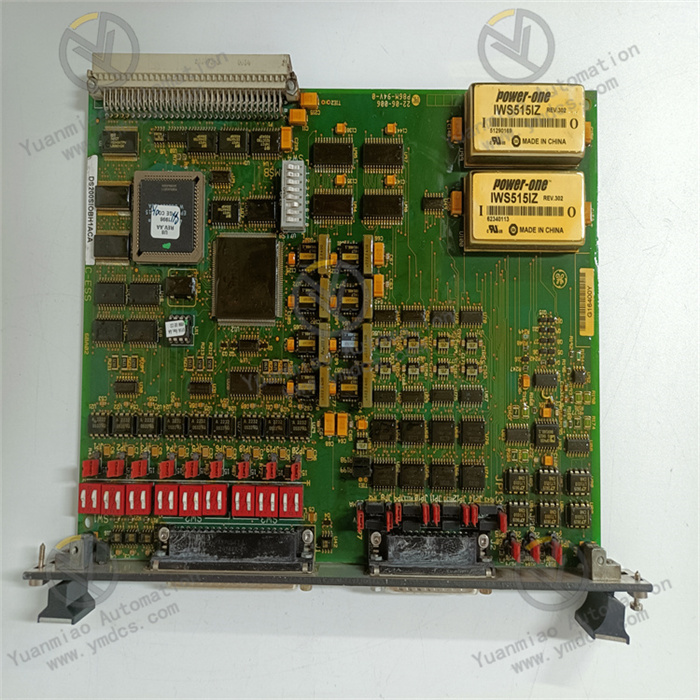

- Power Module

- Provides stable power for internal controller components (e.g., 24VDC). Some models support wide voltage input (e.g., 85–264VAC) with surge and overvoltage protection.

Application Scenarios

- Manufacturing: Production line control, assembly equipment, packaging machinery, etc.

- Process Automation: Chemical, water treatment, and HVAC (heating, ventilation, and air conditioning) systems.

- Energy and Power: Substation automation, small-scale power generation equipment control.

- Building Automation: Elevator control, intelligent building management systems (BMS).