Description

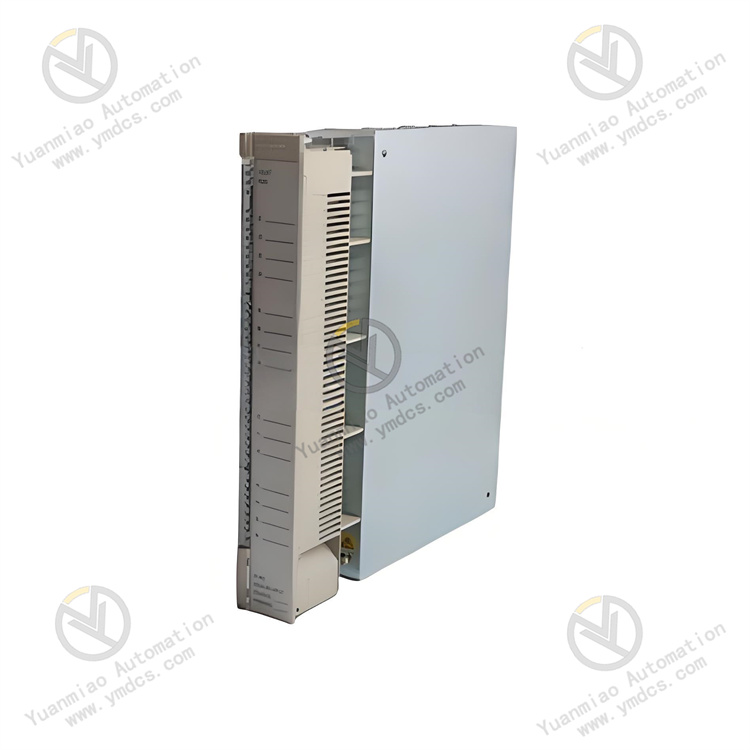

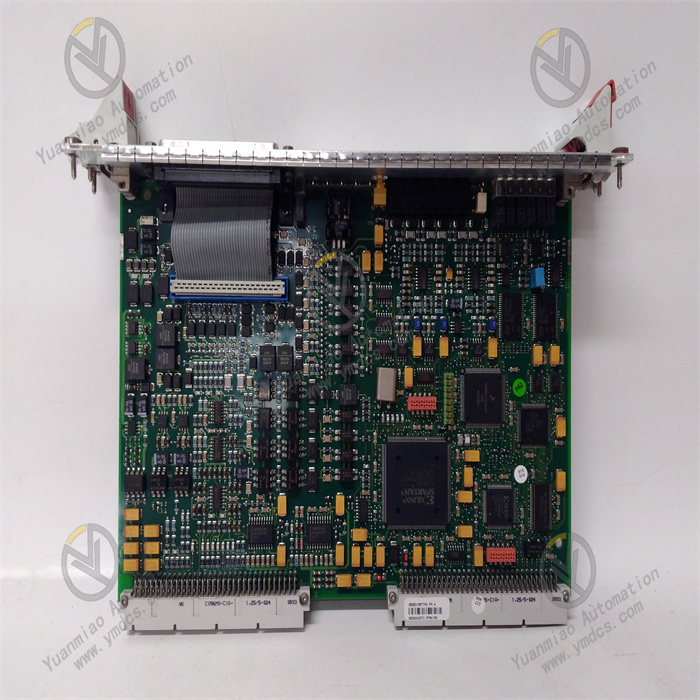

ABB CI630 3BSE011000R1

I. Overview

The CI630 3BSE011000R1 is an industrial communication module and a core component of the Advant OCS system. As an Ethernet communication interface module, its main function is to enable high-speed data interaction between the control system, upper management systems, and third-party devices, supporting standard network protocols such as TCP/IP and UDP. Suitable for scenarios requiring real-time data monitoring and remote management in power, chemical, manufacturing, and other industries, this module constructs industrial Ethernet communication networks through standardized interfaces, serving as a key hub connecting field devices and management layers in Distributed Control Systems (DCS).

II. Functional Features

High-Speed Ethernet Communication

- Supports 10/100 Mbps adaptive Ethernet interfaces, compatible with IEEE 802.3 standards to meet real-time data transmission requirements.

- Supports protocols such as TCP/IP, UDP, ARP, and ICMP, enabling seamless docking with devices like PLCs, SCADA systems, and HMIs.

High-Reliability Design

- Operating temperature range: -25°C to +70°C, adapting to temperature fluctuations in industrial environments.

- Electromagnetic interference (EMC) resistance complies with EN 61000 standards, ensuring stable operation in complex electromagnetic environments.

- Supports redundant power input (24V DC) to reduce single-point failure risks.

Flexible Configuration and Diagnosis

- Configures network parameters (e.g., IP address, port number, communication protocol) via ABB Control Builder software.

- Built-in LED status indicators (power, communication, link, activity) display the module's operating status in real time, supporting rapid fault localization.

Modularity and Expandability

- Supports hot-swapping, allowing module replacement without shutdown to improve system maintenance efficiency.

- Can form distributed networks with other ABB modules (such as CPU and I/O modules) to adapt to complex industrial control scenarios.

III. Technical Parameters

| Parameter Category | Specific Indicators |

|---|---|

| Power Supply Voltage | 24V DC (±10%), power consumption ≤8W |

| Communication Interfaces | 2×RJ45 Ethernet interfaces (10/100 Mbps adaptive), supporting redundant network links |

| Protocol Support | TCP/IP, UDP, DHCP, SNMP, Modbus TCP, Profinet (optional configuration) |

| Node Capacity | Single network supports up to 254 device nodes |

| Physical Dimensions | 170mm × 40mm × 110mm, weight approx. 0.25kg |

| Protection Level | IP20 (suitable for installation in control cabinets) |

| Certification Standards | CE, UL, ISO 9001, compliant with IEC 61131-2 industrial communication standards |

| Operating Temperature | -25°C to +70°C, storage temperature: -40°C to +85°C |

IV. Working Principle

The core function of the CI630 module is to enable data interaction and protocol conversion in industrial Ethernet, with its workflow divided into the following stages:

Data Collection and Transmission

- As an Ethernet node, it actively or passively receives real-time data (e.g., process parameters, device status) from field devices (such as sensors and PLCs), packages the data via the TCP/IP protocol, and transmits it to the main control system.

- Receives control commands issued by the upper management system, parses them, and forwards them to corresponding devices to achieve remote control (e.g., device start/stop, parameter adjustment).

Protocol Processing Mechanism

- Supports multi-protocol conversion: For example, converting data from Modbus TCP protocol to ABB system-specific protocols and vice versa to ensure compatibility with devices from different manufacturers.

- Supports data caching and queue management to avoid data packet loss under high loads and ensure communication real-time performance.

Network Management and Diagnosis

- Built-in network management functions monitor link status (e.g., bandwidth utilization, bit error rate). When network interruptions or anomalies are detected, alarms are triggered via LED indicators and system logs.

- Supports DHCP for automatic IP address assignment or manual static IP configuration to adapt to different network architecture requirements.

V. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Power indicator (PWR) not lit | Loose power connection or abnormal voltage | Check power cable connections, measure input voltage within 24V DC (±10%), and replace faulty power modules. |

| Network indicator (LINK) off | Network cable failure, poor interface contact, or IP conflict | Detect cable continuity with a multimeter, replace RJ45 connectors, check IP address settings, and ensure no duplicate addresses. |

| High data transmission delay or packet loss | Excessive network load, mismatched communication rate, or interference | Reduce network load (split network segments), adjust port rate to 100 Mbps (full-duplex mode), add shielding to network cables, and keep away from electromagnetic interference sources. |

| Module unresponsive to configuration commands | Incorrect software configuration or abnormal module firmware | Restart the module and reconfigure parameters via Control Builder; if ineffective, attempt to upgrade the module firmware to the latest version. |

| Protocol conversion failure | Incorrect protocol parameter configuration (e.g., port number, parity bit) | Verify protocol parameters (e.g., Modbus TCP port 502) to ensure consistency with docking devices, and restart the module to enable configurations. |

VI. Extended Application Scenarios

The CI630 module is often used with ABB AC800M controllers and S800 I/O modules to build industrial Ethernet communication networks. Typical applications include:

- Power Industry: Enables real-time data interaction between PLCs and monitoring systems (SCADA) in substation automation systems, supporting remote operation and fault early warning.

- Chemical Industry: Transmits on-site temperature, pressure, and other data to central control rooms via Ethernet in reactor control systems, supporting real-time adjustment of process parameters.

- Manufacturing Industry: Connects devices such as robots and CNC machines in intelligent production lines to build Industrial Internet of Things (IIoT), enabling device status monitoring and production process optimization.