Description

Basic Information

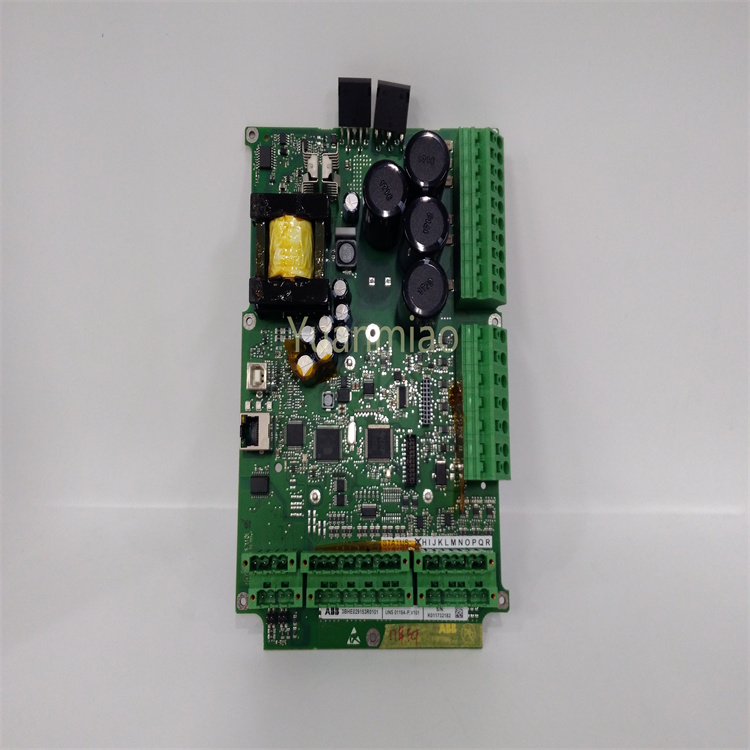

Model: PM866K01

Order Number: 3BSE050198R1

Series: Belongs to ABB's Advant Controller 800xA series or AC800M series.

Type: A high-performance processor unit that provides powerful and reliable solutions for industrial automation and process control.

Order Number: 3BSE050198R1

Series: Belongs to ABB's Advant Controller 800xA series or AC800M series.

Type: A high-performance processor unit that provides powerful and reliable solutions for industrial automation and process control.

Technical Parameters

Processor: Equipped with a dual-core ARM Cortex-A9 or PowerPC 750 processor, with a main frequency of up to 1GHz, capable of rapidly processing complex control tasks to ensure fast response and efficient computation.

Memory: Supports up to 8GB RAM and 8MB Flash, meeting data storage and processing requirements in different application scenarios.

Communication Interfaces:

Memory: Supports up to 8GB RAM and 8MB Flash, meeting data storage and processing requirements in different application scenarios.

Communication Interfaces:

- Ethernet Ports: Support multiple protocols such as Modbus TCP/IP, PROFIBUS, and DeviceNet, facilitating network communication and data exchange with other devices.

- Serial Ports: Include RJ45 and RS-232C interfaces for connecting configuration tools or other devices with serial communication capabilities.

Power Supply: Typically powered by 24V DC, with dual-power redundant input, DC1500V voltage isolation, and reverse connection protection. Power consumption is less than 4W, with industrial terminal interfaces.

Physical Characteristics: - Dimensions: Width 119 mm (measured along the DIN rail, with an additional 4 mm protrusion of CEX bus contacts when uninstalled), depth 135 mm (measured from the wall), height 186 mm (vertically measured, including locking devices).

- Weight: Approximately 1200 grams (packaged).

Environmental Adaptability: - Operating Temperature: -40°C to +70°C.

- Storage Temperature: -40°C to +85°C.

- Relative Humidity: 5% to 95%, non-condensing.

- Shock Resistance: 15g.

- Vibration Resistance: 2g.

Functional Features

High Reliability: Suitable for harsh industrial environments, rigorously tested to ensure stable operation, with reliable and simple fault diagnosis procedures.

Flexible Configuration: Supports multiple I/O modules, allowing flexible configuration according to application needs. Its modular design enables gradual expansion.

Compatibility: Compliant with the IEC 61131-3 standard and supports multiple programming languages such as Ladder Diagram and Structured Text.

Flexible Configuration: Supports multiple I/O modules, allowing flexible configuration according to application needs. Its modular design enables gradual expansion.

Compatibility: Compliant with the IEC 61131-3 standard and supports multiple programming languages such as Ladder Diagram and Structured Text.

Application Areas

Power Industry: Used for control in power plants and substations to achieve automated monitoring and management of power generation, transmission, and distribution.

Petrochemical Industry: Applied in process control, safety protection, quality monitoring, etc., such as precise control of parameters like temperature, pressure, and flow in chemical production to ensure production safety and product quality.

Metallurgical Industry: Used to control production equipment in steel rolling and steelmaking processes, achieving automation and optimization of production processes to improve production efficiency and product quality.

Paper Industry: Can be used for pulp manufacturing and paper processing control, monitoring and controlling various parameters in the papermaking process to ensure stable paper quality.

Manufacturing Industry: Commonly used for automated production line control, achieving coordinated control of various equipment on the production line to improve production efficiency and product consistency.

Other Industries: Also widely used in mining, transportation, environmental monitoring, etc., such as automation control systems in mining, traffic signal systems and rail transit automation in transportation, and monitoring of environmental parameters like atmospheric conditions and water quality in environmental monitoring.

Petrochemical Industry: Applied in process control, safety protection, quality monitoring, etc., such as precise control of parameters like temperature, pressure, and flow in chemical production to ensure production safety and product quality.

Metallurgical Industry: Used to control production equipment in steel rolling and steelmaking processes, achieving automation and optimization of production processes to improve production efficiency and product quality.

Paper Industry: Can be used for pulp manufacturing and paper processing control, monitoring and controlling various parameters in the papermaking process to ensure stable paper quality.

Manufacturing Industry: Commonly used for automated production line control, achieving coordinated control of various equipment on the production line to improve production efficiency and product consistency.

Other Industries: Also widely used in mining, transportation, environmental monitoring, etc., such as automation control systems in mining, traffic signal systems and rail transit automation in transportation, and monitoring of environmental parameters like atmospheric conditions and water quality in environmental monitoring.

Common Faults and Solutions for ABB PM866K01 3BSE050198R1

I. Power Supply Faults

- Controller Fails to Power On / Power Indicator Off

- Check whether the power input voltage (AC/DC) meets specifications (e.g., 24V DC or 100-240V AC), and measure the voltage at the input terminals with a multimeter.

- Re-plug the power module to ensure a secure connection; replace the power module with the same model (e.g., ABB 3BSE050198R1 compatible power module) if damaged.

- If there is a fuse, check if it is blown and replace it with a fuse of the same specification (power off before operation).

- Abnormal power input (e.g., unstable voltage, open circuit).

- Damaged or poorly connected power module.

- Internal fuse blown (built-in fuse in some models).

- Possible Causes:

- Solutions:

- Flickering/Abnormal Power Indicator

- Use a voltage regulator or isolation transformer to stabilize the power input.

- Check the connection of the redundant power module and test the primary-backup power switching function (refer to the manual for configuration).

- Contact ABB technical support or replace the controller if an internal fault is confirmed.

- Fluctuating power input or harmonic interference.

- Abnormal switching between primary and backup power in a redundant power configuration.

- Fault in the controller's internal power management chip.

- Possible Causes:

- Solutions:

II. Communication Faults

- Ethernet/Fieldbus Communication Interruption

- Re-plug the network cable and use a cable tester to check connectivity; replace the faulty network port or module (if hot-swappable).

- Check the bus terminal resistors (typically requiring a 120Ω resistor at the first and last devices) and inspect the cable for short circuits or open circuits.

- Ensure that communication parameters (e.g., IP, port, protocol) in the programming software match the actual device, and retry after restarting the controller.

- Loose network cable, damaged interface, or IP address conflict (in Ethernet scenarios).

- Incorrect setting of fieldbus (e.g., PROFIBUS, CEX bus) terminal resistors or bus cable faults.

- Incorrect configuration of communication protocols (e.g., baud rate, slave address mismatch).

- Possible Causes:

- Solutions:

- Unstable Communication Speed or Packet Loss

- Isolate communication cables from high-power lines, use shielded cables, and ensure reliable grounding.

- Optimize the network architecture, divide VLANs, or add switches to distribute data; reduce the number of slaves on the same bus.

- Upgrade the communication module firmware to the latest version via ABB Control Builder M.

- Electromagnetic interference (e.g., nearby high-power equipment).

- Excessive network load (e.g., simultaneous communication by multiple devices).

- Outdated firmware version of the communication module, leading to compatibility issues.

- Possible Causes:

- Solutions:

III. Processor and Memory Faults

- Frequent Controller Restarts or Freezes

- Check memory usage by the program, optimize the code, or expand memory (if there is an SD card slot, add storage media).

- Clean the controller's cooling vents, ensure good ventilation in the installation environment, and avoid high-temperature environments (operating temperature: -40°C ~ +70°C).

- Restore factory settings (backup the program first) or re-download the firmware to troubleshoot software issues; replace the controller if a hardware fault is confirmed.

- Insufficient memory (oversized program or excessive running tasks).

- Processor overheating (poor heat dissipation).

- Firmware defects or logical errors in the program (e.g., infinite loops).

- Possible Causes:

- Solutions:

- Data Loss or Inability to Save Programs

- Replace the built-in lithium battery (typically a 3.6V non-rechargeable battery, replace while powered to avoid data loss).

- Format the SD card or replace it with a new one, and re-download the program; if the Flash is damaged, return it for repair or replace the controller.

- Depleted backup battery (inability to save real-time clock and non-volatile data).

- Damaged storage media (e.g., Flash or SD card).

- Possible Causes:

- Solutions:

IV. Hardware Module and Expansion Faults

- Expansion Module Not Recognized

- Reinstall the module to ensure the latch is locked; clean the interface contacts with anhydrous alcohol.

- Check the expansion bus cable connection and replace it with a spare cable.

- Update the module firmware to a version compatible with the controller (refer to ABB official documentation).

- Improper module installation or oxidized interfaces.

- Faults in expansion bus (e.g., CEX bus) connection cables.

- Incompatibility between module firmware and controller.

- Possible Causes:

- Solutions:

- Abnormal I/O Module Signals (e.g., No Input Response, No Output Action)

- Check the wiring against the diagram and measure signals with a multimeter (e.g., input voltage, output current).

- Replace faulty channels or modules and check if the load meets specifications (e.g., maximum current of relay output modules).

- Confirm that I/O configuration in the programming software matches the hardware, download the latest configuration, and restart the controller.

- Incorrect wiring (e.g., reversed polarity, short circuit).

- Damaged module channels or overload (e.g., voltage/current exceeding rated values).

- Incorrect configuration of I/O addresses or failure to enable modules in the program.

- Possible Causes:

- Solutions:

V. Environmental and Reliability Faults

- Faults Caused by Excessive Environmental Temperature

- Clean or replace the control cabinet cooling fans to ensure air circulation; install temperature sensors to monitor the environment.

- Reposition the installation to maintain a safe distance from heat sources (recommended ≥10cm).

- Poor ventilation in the control cabinet or faulty cooling fans.

- Installation near heat-generating equipment (e.g., inverters, motors).

- Possible Causes:

- Solutions:

- Poor Contact Caused by Vibration or Dust

- Regularly check the tightness of mounting screws and use lock washers.

- Clean the controller's surface and interior with compressed air (power off before operation), and use dust-proof enclosures (e.g., IP65 protection grade accessories) if necessary.

- Loose DIN rail mounting screws causing module shaking.

- Dust entering interfaces or circuit boards, leading to short circuits.

- Possible Causes:

- Solutions:

VI. General Fault Troubleshooting Process

- Power Cycle: Simple faults (e.g., temporary communication interruptions) may be resolved by restarting.

- Replacement Method: Replace suspected faulty components with known good modules/cables to locate the problem.