Description

ABB CI522 3BSE012790R1

I. Overview

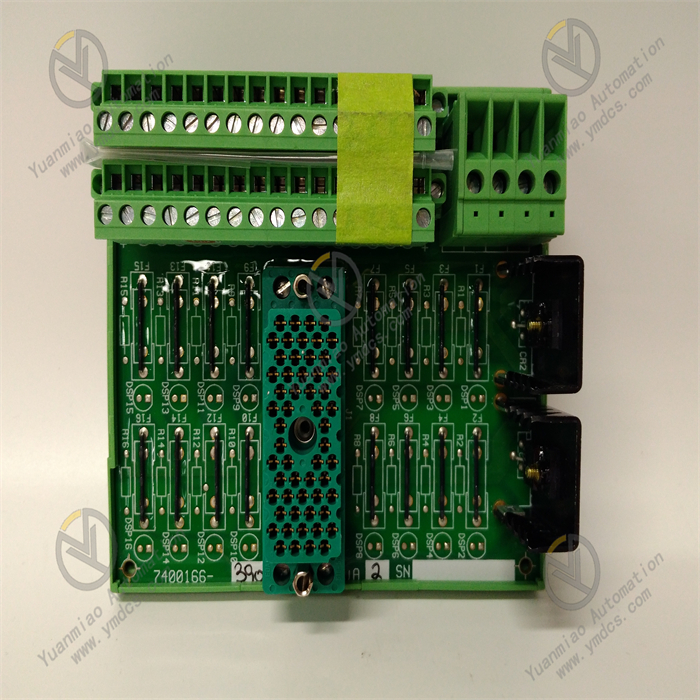

The CI522 3BSE012790R1 is an industrial automation communication module launched by ABB, serving as a key component of the Advant Master system. As a fieldbus interface module, its core function is to enable high-speed data transmission and communication protocol conversion between the control system and field devices. It is suitable for industrial scenarios with extremely high requirements for reliability and real-time performance, such as metallurgy, chemical engineering, and power. Through standardized interfaces and protocols, the module ensures stable connection between the system and devices like sensors and actuators, serving as an important link in building Distributed Control Systems (DCS).

II. Functional Features

Multi-Protocol Compatibility and High-Speed Communication

- Supports PROFIBUS DP V1 protocol, compatible with master-slave communication mode, and enables seamless docking with third-party devices (such as PLCs and intelligent instruments).

- The maximum communication rate reaches 12 Mbps, meeting the demand for fast data interaction in real-time control scenarios.

High-Reliability Industrial Design

- Operating temperature range: -40°C to +70°C, adapting to harsh industrial environments such as high and low temperatures.

- Electromagnetic interference (EMC) resistance design complies with industrial standards, reducing the impact of on-site electromagnetic interference on communication.

- Supports redundant power input, reducing the risk of downtime caused by power failures.

Flexible Configuration and Diagnostic Functions

- Supports parameter configuration and network topology design through ABB Control Builder software.

- Built-in real-time diagnostic mechanism visually displays the module status through LED indicators (such as power, communication, and fault), supporting fault localization to the channel level.

Hot Swapping and Modular Expansion

- Supports hot swapping under power, allowing module replacement without shutdown, improving system maintenance efficiency.

- Can be used in combination with other ABB modules (such as AI/AO modules and safety modules) to meet complex control requirements.

III. Technical Parameters

| Parameter Category | Specific Indicators |

|---|---|

| Power Supply Voltage | 24V DC (±10%), power consumption ≤10W |

| Communication Interface | PROFIBUS DP (DB9 interface), supports redundant communication links |

| Number of Nodes | Single network supports up to 126 slave devices |

| Physical Characteristics | Dimensions: 234mm × 27mm × 112.5mm, weight approximately 0.3kg |

| Protection Level | IP20 (panel mounting), suitable for control cabinet environments |

| Certification Standards | Industrial certifications such as CE, UL, ISO 9001, compliant with IEC 61131-2 standard |

IV. Working Principle

The working process of the CI522 module can be divided into four links: data collection, protocol conversion, control execution, and status monitoring:

Data Interaction Logic

- As a PROFIBUS DP master station, it periodically polls slave devices (such as sensors and valves) to collect real-time data (such as temperature, pressure, and switching quantities).

- Converts analog/switching signals from field devices into digital signals, which are packaged and transmitted to the main control system via the PROFIBUS protocol.

Protocol Processing Mechanism

- Receives control commands issued by the main control system, parses them, and sends them to corresponding slave devices via the PROFIBUS protocol to achieve action control over actuators (such as motors and valves).

- Supports aperiodic data transmission (such as device parameter configuration and fault alarms), ensuring both real-time performance and flexibility.

Status Monitoring and Diagnosis

- Continuously monitors network communication quality (such as signal strength and bit error rate). When communication interruption or slave device failure is detected, it reports anomalies through LED indicators and system logs.

- Built-in watchdog timer automatically restarts the module in case of abnormal shutdown, ensuring continuous system operation.

V. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Power indicator (PWR) not lit | Loose power connection or abnormal voltage | Check power cable connection, measure input voltage within 24V DC (±10%), and replace the power module. |

| Abnormal flashing of communication indicator (COM) | PROFIBUS cable failure or slave address conflict | Detect cable continuity with a multimeter, reconfigure slave addresses, and ensure no duplicate addresses in the network. |

| Frequent error reporting or shutdown of the module | Electromagnetic interference or poor heat dissipation | Add a shielding layer to the module, check the ventilation of the control cabinet, clean dust from the heat dissipation holes, and ensure the operating temperature is between -40°C and +70°C. |

| No response from slave devices | Incorrect protocol configuration or poor interface contact | Check PROFIBUS protocol parameters of the module (such as baud rate and parity), re-plug the interface, or replace the DB9 connector. |

| High data transmission delay | Mismatch between communication rate and slave station or excessive network load | Reduce the baud rate (e.g., adjust from 12 Mbps to 1.5 Mbps), and split the network topology to reduce the number of slave stations in a single segment. |

VI. Extended Application Scenarios

The CI522 module is often used in conjunction with ABB AC800M controllers and S800 I/O modules to form a complete distributed control system. Typical applications include:

- Metallurgy industry: Communication interfaces for blast furnace temperature control and rolling mill speed regulation systems;

- Power industry: Data interaction between PLCs and relay protection devices in substation automation systems;

Petrochemical industry: Communication hubs for field devices in temperature/pressure closed-loop control of reactors.