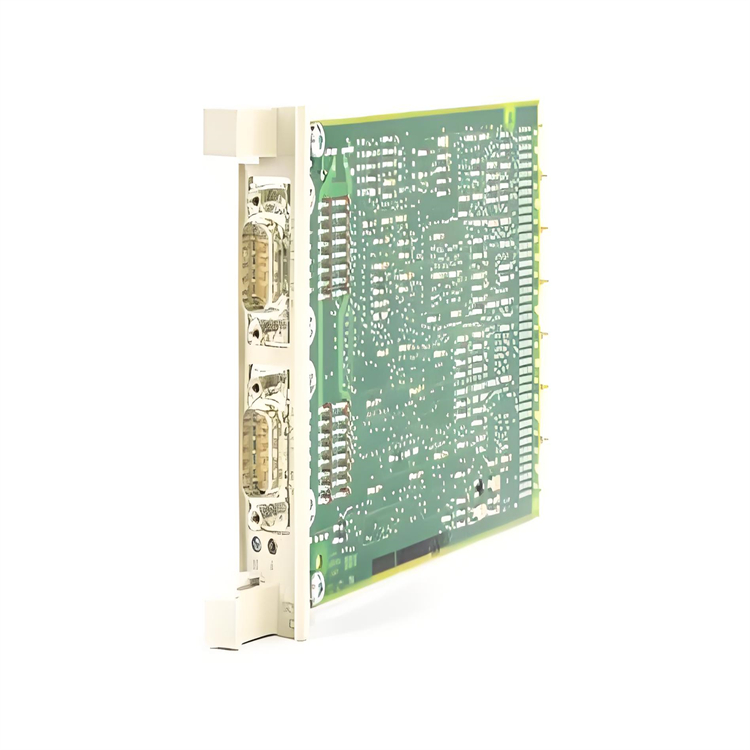

Description

ABB CI535 3BSE003830R1

Functional Features

- Powerful Processing Capability: It typically has high-performance processing capability, capable of handling complex control algorithms and data processing tasks, supporting real-time control and data processing, and meeting the requirements of complex industrial control systems.

- Real-time Performance: It supports real-time processing to ensure timely response to control and data needs, enabling quick response and processing of various parameters and events in the industrial production process.

- Multitasking: Some automation processor modules may support multitasking, allowing simultaneous processing of multiple control tasks and data streams to improve system operation efficiency and flexibility.

- Communication Capability: Equipped with various communication interfaces, including Ethernet, serial communication interfaces (such as RS-232, RS-485), and industrial communication protocols (such as Modbus, Profibus, DeviceNet, etc.), to communicate with other devices and systems for system integration and expansion.

Technical Parameters

- Voltage: Generally 24 volts direct current.

- Current: Possibly 2.5A.

- I/O Channels: Usually 8 input channels and 8 output channels, which can connect various external devices such as sensors and actuators to realize monitoring and control of industrial processes.

- Operating Temperature: With a wide operating temperature range, generally -40°C to 70°C, it can adapt to various harsh industrial environments.

- Dimensions: Approximately 120 mm × 80 mm × 35 mm, with a compact structure that saves installation space and facilitates installation in various industrial equipment and control cabinets.

Application Fields

- Industrial Automation: In factories and production lines, it is used to implement complex control logic, algorithms, and data processing to optimize production processes, achieve precise control and monitoring of production equipment, and improve production efficiency and product quality.

- Power System: In the power industry, it can be used to monitor power plants, substations, or distribution systems, monitor and control the operating status of power equipment, and ensure the stable operation of the power system.

- Process Control: In process industries such as chemical, petroleum, and natural gas, it is used to monitor and regulate production processes, precisely control process parameters such as temperature, pressure, and flow, and ensure the safety and stability of production processes.

- Other Fields: It can also be applied to multiple fields, including machine control and production line control in manufacturing, lighting and HVAC system control in building automation, logic control and monitoring of traffic signal control, railway, and airport control systems in transportation, as well as water treatment process monitoring and control in water treatment and environmental protection, and production process control in the food and beverage industry.