Description

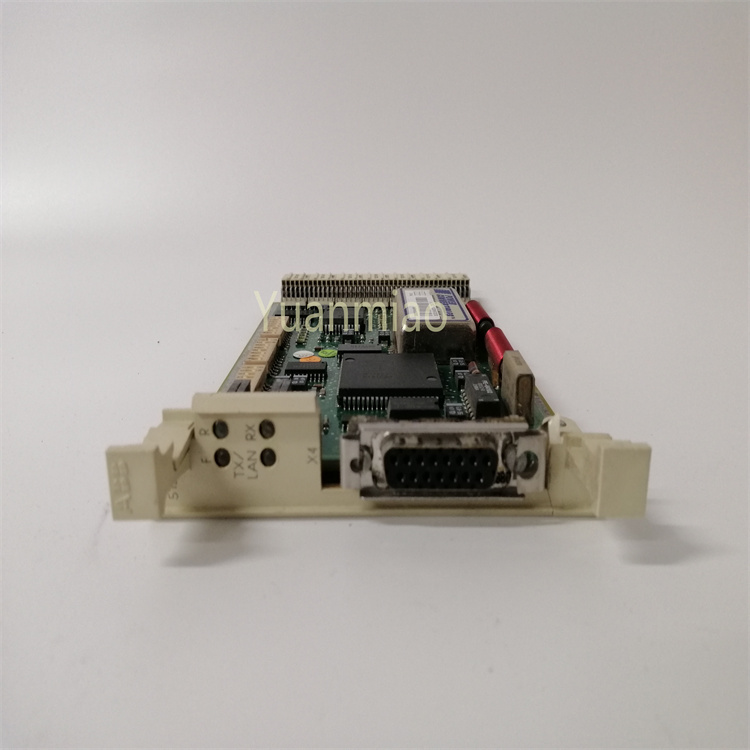

DS215TCEAG1BZZ01A

I. Overview

GE DS215TCEAG1BZZ01A is an important product of GE (General Electric) and part of the VersaMax series of controllers. It plays a crucial role in various control applications within industrial and commercial environments. As a core component of the control system, it undertakes multiple important tasks such as data input and output, signal processing, and logical control. It is widely applied in many fields, including industrial automation, process control, robot control, and building automation. In industrial automation production lines, it precisely controls equipment operation, efficiently collects and monitors data. In process control, it helps ensure the stable operation of technological processes in industries such as chemicals, petroleum, and pharmaceuticals. In robot control, it is responsible for processing sensor signals and accurately controlling robot movements.

II. Functional Features

- High - performance Data Interaction: It supports multiple communication protocols such as Modbus, ensuring fast and accurate data transmission. It can efficiently interact with other devices or systems, meeting the strict requirements for data transmission efficiency and accuracy in complex industrial environments.

- Strong Environmental Adaptability: With an ultra - wide operating temperature range from - 40°C to + 70°C, it can operate stably in harsh industrial environments, whether extremely hot or cold, adapting to the usage requirements of different regions and working conditions.

- Convenient System Integration: It can be seamlessly integrated with other components of the GE VersaMax series, greatly simplifying the system design and installation process, reducing the difficulty and cost of system construction, and improving the compatibility and stability of the overall system.

- Reliable Safety Assurance: It is equipped with multiple built - in safety functions. Starting from aspects such as data encryption, access rights control, and transmission verification, it comprehensively protects the security and integrity of data during the transmission process, preventing data leakage and tampering.

III. Technical Parameters

- Input Voltage: 24VDC, which can be adapted to common DC power inputs, ensuring stable power supply for the device.

- Input Current: 160mA, with a reasonable current input requirement to ensure that the power consumption of the device is within a reasonable range during operation.

- Output Voltage: 24VDC, which can provide a stable DC voltage output for external actuators and other components.

- Output Current: 2A, which can meet the current requirements of various loads and has strong driving capabilities.

- Operating Temperature Range: - 40°C to + 70°C, demonstrating strong environmental adaptability.

- Storage Temperature Range: - 40°C to + 85°C, ensuring the reliability of the device when stored in different temperature environments during non - operation.

- Dimensions: 2.4 x 3.5 x 5.1 inches. The compact size design makes it easy to install and arrange in various control cabinets and equipment spaces.

IV. Working Principle

When the control system is in operation, DS215TCEAG1BZZ01A first receives analog signals from sensors, such as the temperature analog quantity from a temperature sensor and the pressure analog signal from a pressure sensor. Its internal circuit conditions these analog signals, and then the analog - to - digital conversion module precisely converts the analog signals into digital signals for processing by the processor. The processor performs calculations and judgments on the digital signals according to the preset control logic, and then generates corresponding control signals based on the processing results. These control signals are then converted into analog signals by the digital - to - analog conversion module and output to the actuators, such as driving the motor to run and controlling the valve opening, thus achieving precise control of the industrial process.

V. Common Faults and Solutions

- Abnormal Data Transmission

- Fault Phenomenon: When the device communicates with other systems, data packet loss, errors, or transmission interruptions occur.

- Solution: First, check whether the communication lines are loose or damaged. If there are problems, repair or replace the lines in a timely manner. Then, confirm whether the communication protocol settings are correct, re - check and adjust the protocol matching with other devices. If the problem persists, consider whether the communication interface of the module is damaged. You can try replacing the communication interface module for testing.

- Unstable Output Signal

- Fault Phenomenon: The voltage or current value of the signal output to the actuator fluctuates greatly, resulting in abnormal actuator operation.

- Solution: Check whether there are short - circuit or overload conditions in the output load and eliminate load faults. Check whether the power supply of the module is stable. You can use a multimeter to detect whether the power supply voltage is within the normal range. If the power supply is unstable, check the power supply lines and related power supply equipment. If the above are normal, it may be a fault in the internal output circuit of the module, and professional maintenance personnel should be contacted for module repair.

- Device Overheating

- Fault Phenomenon: After the device runs for a period of time, the temperature of the casing is too high, and even the overheating protection mechanism is triggered.

- Solution: Check the heat dissipation environment of the device to ensure good ventilation around and no debris blocking the heat dissipation. Check whether the cooling fan is operating normally. If the fan fails, replace it in a timely manner. If the device runs under high load for a long time, consider optimizing the control program, reasonably distributing the workload, and reducing the device operating power consumption.