Description

Performance Characteristics

Low Power Consumption Design: The current consumption is less than 50mA@24V DC during operation, offering excellent energy-saving effects. It is suitable for industrial environments with strict power consumption requirements, helping reduce overall energy consumption and operational costs.

Long-Distance Communication: Using twisted-pair cables, the communication distance can reach 1000 meters, meeting the needs of long-distance communication between devices in large industrial sites. This reduces the use of signal relay equipment and lowers system costs and complexity.

Wide Temperature Range: The module operates within a temperature range of -20°C to +60°C and stores at -40°C to +85°C, adapting to various harsh industrial environments. It can operate stably and reliably in high-temperature areas near furnaces or cold outdoor environments.

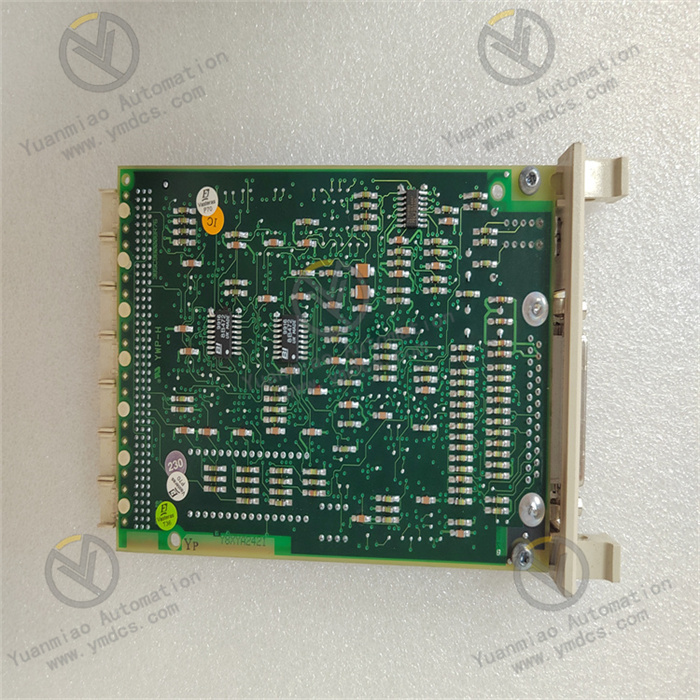

Compact and Lightweight: With dimensions of 94.3mm×86.5mm×31.75mm and a weight of only 0.15kg, it is small and lightweight, facilitating installation and maintenance. It can be easily integrated into various industrial devices and systems without occupying excessive space.

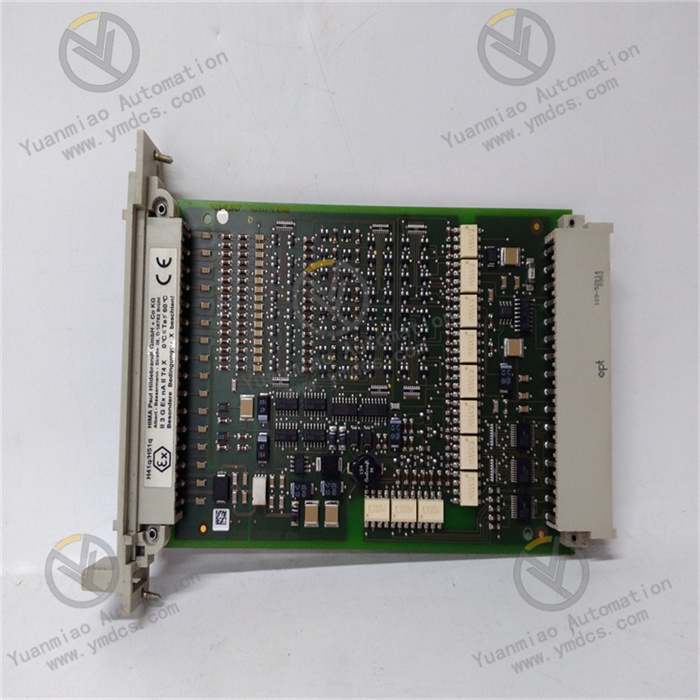

Reliable Connection: Equipped with an M12 connector, it ensures compatibility with existing industrial infrastructure, simplifying module installation and cabling. It also enhances connection stability and reliability, reducing communication failures caused by poor connections.

Technical Parameters

- Communication Parameters:

- Protocol: Supports LonWorks communication protocol.

- Rate: Transmission rate of 1250 kbit/sec.

- Distance: Up to 1000 meters via twisted-pair cable.

- Electrical Parameters:

- Operating Voltage: Typically 24V DC (-15% to +20% tolerance).

- Current Consumption: Less than 50mA@24V DC.

- Environmental Parameters:

- Operating Temperature: -20°C to +60°C.

- Storage Temperature: -40°C to +85°C.

- Mechanical Parameters:

- Dimensions: 94.3mm×86.5mm×31.75mm.

- Weight: 0.15kg.

- Connection Parameters: Uses M12 connector to ensure compatibility with existing industrial infrastructure.

Working Principle

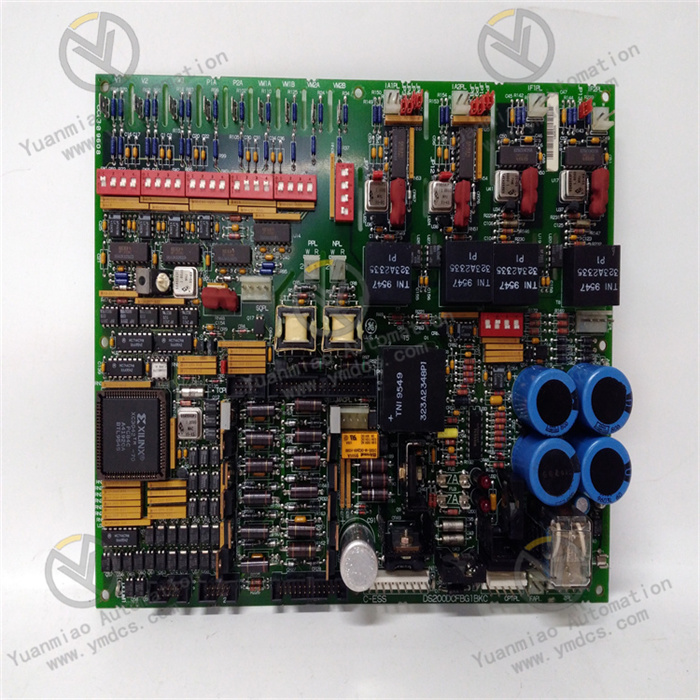

Data Processing and Conversion: The module receives signals or data from external devices (e.g., sensors, controllers) and converts them into LonWorks-compatible formats for network transmission. It also receives LonWorks-formatted data from other network devices and converts it into signals/data understandable by external devices, enabling data interaction between different devices.

Network Topology and Routing: Supports multiple network topologies (e.g., bus, star, hybrid). The module determines data transmission paths and methods based on network topology and configuration information to achieve efficient data routing. For example, in complex industrial automation systems, multiple CI572 modules connecting different devices use network topology and routing functions to ensure accurate data transmission between devices and avoid conflicts or loss.

Power Management: The module obtains operating energy through a stable power input (typically 24V DC). Internal power management circuits convert the input power into different voltage levels required by various module components, providing stable power for chips, communication circuits, etc., to ensure normal operation. It also has power protection functions (e.g., overcurrent protection, overvoltage protection) to prevent module damage from power anomalies.

Communication Signal Transmission: Transmits communication signals via twisted-pair cables. When sending data, the module converts digital signals into electrical signals suitable for twisted-pair transmission and sends them according to the LonWorks protocol’s encoding and transmission rate. When receiving data, it converts electrical signals from twisted-pair cables into digital signals, extracts valid data after decoding and verification, and forwards it for subsequent processing.

Application Areas

Intelligent Building Control Systems: Can be integrated into lighting, air conditioning, and security systems of intelligent buildings to achieve interconnection and centralized control of subsystems, enabling intelligent energy management and environmental control to provide users with a more comfortable, safe, and energy-efficient building environment.

Transportation Systems: Used in rail transit, intelligent transportation, and other fields to connect traffic signal devices, monitoring equipment, and vehicle control systems, enabling real-time transmission and sharing of traffic information to improve transportation system efficiency and safety and ensure smooth traffic flow.

Energy Management Systems: Suitable for energy industries (e.g., power, petroleum, chemicals) to connect devices and systems in energy production, transmission, distribution, and consumption processes, enabling real-time monitoring and analysis of energy data, optimizing energy scheduling and management, improving energy efficiency, and reducing energy losses.

Operation Guide for ABB CI572 3BSE017712R1

- Select Installation Location: Choose a dry, well-ventilated, temperature-appropriate location away from interference sources. Ensure the module is firmly installed to avoid vibration and impact.

- Connect Cables: Use suitable cables to connect the CI572 module to other devices via the M12 connector, ensuring secure connections to prevent looseness or poor contact. Pay attention to connection polarity and pin definitions, and follow the manual or markings for correct wiring.

Power Connection - Confirm Power Parameters: Check if the power supply voltage meets the module’s requirements (typically 24V DC with a voltage fluctuation range of -15% to +20%).

- Connect Power Supply: Connect the positive and negative poles of the power supply to the corresponding power pins or terminals of the module, ensuring reliable connections to prevent short circuits or open circuits.

Communication Setup - Configure Communication Parameters: Set CI572 module parameters (e.g., node address, communication rate) via relevant software tools or configuration interfaces based on specific application scenarios and communication needs with other devices. These parameters must match those of other devices in the same LonWorks network to ensure normal communication.

- Network Topology Setup: If multiple CI572 modules or other LonWorks devices form a network, reasonably set up and plan the network topology (including subnet division, routing configuration, etc.) to ensure accurate and efficient data transmission.

Function Testing - Basic Function Test: After installation and setup, perform basic function tests to check if the module powers on normally and can communicate simply with other known devices (e.g., sending and receiving test data) to ensure basic communication functionality.

- Comprehensive Function Test: Conduct more comprehensive tests based on the module’s specific application requirements (e.g., real-time data collection and transmission, remote device control) to check if the module meets practical application needs.

- Regular Inspections: Regularly check the module’s operating status, including indicator lights, temperature, and abnormal noises, to identify potential issues promptly. Inspect cable connections for looseness and power supply stability.

- Cleaning and Maintenance: Regularly clean dust and dirt from the module’s surface to prevent heat dissipation issues and normal operation. Before cleaning, disconnect the power supply and use a clean, soft cloth for wiping.

- Software Updates: Monitor ABB’s official software update information for the CI572 module and perform timely upgrades as needed to enhance performance, stability, and new features while fixing potential vulnerabilities and issues.