Description

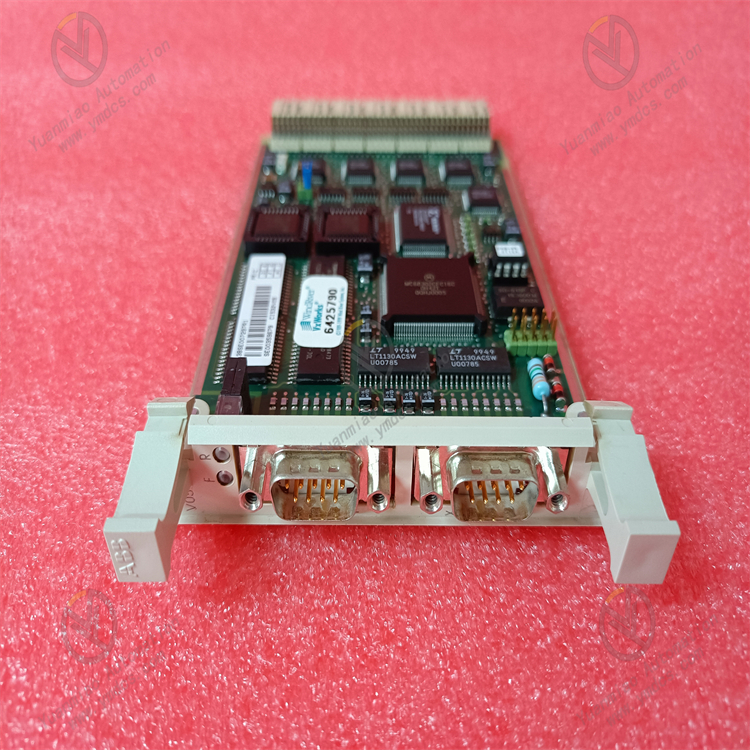

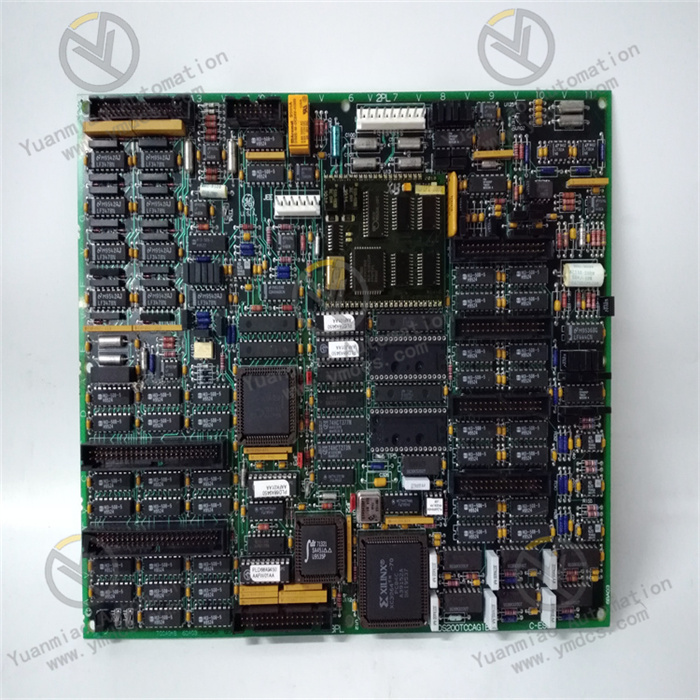

IC698CMX016

I. Overview

GE IC698CMX016 is a compact backplane communication module in the PACSystems RX7i series introduced by General Electric (GE). The PACSystems RX7i series holds a significant position in the field of industrial automation due to its high performance, reliability, and flexible expandability, being widely used in industries such as power, petrochemicals, and manufacturing. As a key component of the series, the IC698CMX016 is primarily responsible for enabling high-speed communication between modules on the backplane, ensuring accurate data transmission and interaction in control systems. It serves as a vital foundation for building stable and efficient industrial control systems, capable of connecting CPU modules, I/O modules, communication modules, etc., to enable collaborative operation and achieve precise control and monitoring of industrial production processes.

II. Functional Features

- High-speed Communication Capability: Supports high-speed backplane communication protocols with a data transmission rate of [X] Mbps, enabling fast and stable transmission of large volumes of data to meet the real-time requirements of industrial automation scenarios. In real-time production line monitoring, it quickly transmits data collected by sensors to the CPU module for processing, promptly reflecting equipment operation status.

- Strong Compatibility: Highly compatible with various modules of the PACSystems RX7i series, including analog I/O modules, digital I/O modules, and other communication modules, allowing seamless integration. This facilitates users in flexibly configuring systems according to different industrial application scenarios, reducing system integration difficulties and costs.

- Redundant Design for Reliable Operation: Features redundant communication functionality. When the primary communication link fails, the backup link automatically switches to ensure uninterrupted system operation, significantly enhancing the reliability and stability of industrial control systems. In continuously producing chemical enterprises, even if a communication link suddenly fails, the redundant design ensures production control remains uninterrupted.

- Flexible Configuration and Diagnostic Functions: Supports flexible configuration via software, allowing users to set communication parameters, addresses, etc., according to actual needs. Meanwhile, the module has built-in fault diagnosis, displaying operating status and fault information in real-time through LED indicators to help users quickly locate fault points, carry out maintenance and repairs promptly, and reduce equipment downtime.

- Good Environmental Adaptability: Operates stably within the temperature range of -40°C to +70°C, adapting to harsh industrial environments. It also has anti-electromagnetic interference capability, enabling normal operation in strong electromagnetic environments to ensure data transmission accuracy.

III. Technical Parameters

- Communication Rate: [X] Mbps (specific value determined according to the actual product)

- Operating Voltage: 24VDC

- Operating Temperature Range: -40°C to +70°C

- Storage Temperature Range: -40°C to +85°C

- Dimensions: [Length × Width × Height, unit: mm] (to be determined based on the actual product)

- Weight: [X] kg (to be determined based on the actual product)

- Backplane Slot Type: Compatible with specific slots of PACSystems RX7i series backplanes

- Number of Supported Modules: Can connect [X] modules (specifically determined by backplane specifications and system configuration)

- Diagnostic Function: Equipped with fault indicator lights to display fault information such as communication status and power status

- Redundancy Support: Supports dual communication link redundancy

IV. Working Principle

The IC698CMX016 is installed on the backplane of the PACSystems RX7i series, establishing communication links with other modules through electrical connections on the backplane. When the system operates, industrial production data (such as temperature, pressure, flow, etc.) collected by sensors is first transmitted to the corresponding I/O modules. After conversion and processing, the I/O modules send the data to the IC698CMX016 via the backplane communication protocol. Upon receiving the data, the IC698CMX016 accurately transmits it to the CPU module for analysis and processing through the high-speed backplane communication network based on the data's target address. After processing, the CPU module reversely transmits control instructions to the corresponding I/O modules via the IC698CMX016, which then control the action of actuators (such as motors, valves, etc.), thus achieving closed-loop control of the industrial production process. Throughout the data transmission process, the redundant communication function of the IC698CMX016 real-time monitors the status of the primary communication link. Once a failure is detected, it immediately switches to the backup link to ensure uninterrupted data transmission.

V. Common Faults and Solutions

- Communication Interruption

- Fault Phenomenon: The module cannot transmit data with other modules, equipment operates abnormally, and the communication status indicator light shows an abnormality.

- Solutions: First, check whether the backplane connection is secure to ensure no looseness or poor contact between the IC698CMX016, the backplane, and other modules. Then, inspect the communication cables for damage or aging, and replace them promptly if problems are found. Next, confirm whether the communication parameter settings (including address, baud rate, etc.) are correct, and recheck and adjust them to the correct parameters. If the above operations are ineffective, it may be a hardware failure of the module, and professional maintenance personnel should be contacted for inspection and repair.

- Data Transmission Error

- Fault Phenomenon: Transmitted data is lost, erroneous, or garbled, leading to inaccurate equipment control.

- Solutions: Check for electromagnetic interference and keep the module and cables away from strong electromagnetic sources such as high-power motors and transformers. Verify whether the backplane power supply is stable using a multimeter to detect if the power voltage is within the normal range. If the power supply is unstable, troubleshoot and repair the power fault. If data errors occur frequently, try resetting the module, restoring default settings, and reconfiguring parameters. If the problem persists, it may be a fault in the module's internal data processing circuit, requiring professional maintenance.

- Module Fault Indicator Light Always On

- Fault Phenomenon: The fault indicator light on the module remains on continuously, indicating a module fault.

- Solutions: Refer to the module user manual to determine the fault type based on the meaning of the fault indicator light. For power faults, check whether the 24VDC power input is normal, including power cord connections and whether the power adapter is damaged. For internal circuit faults, first try powering off and restarting the module to see if the fault is eliminated. If the fault persists after restarting, contact GE official technical support or professional maintenance personnel for further diagnosis and repair.