Description

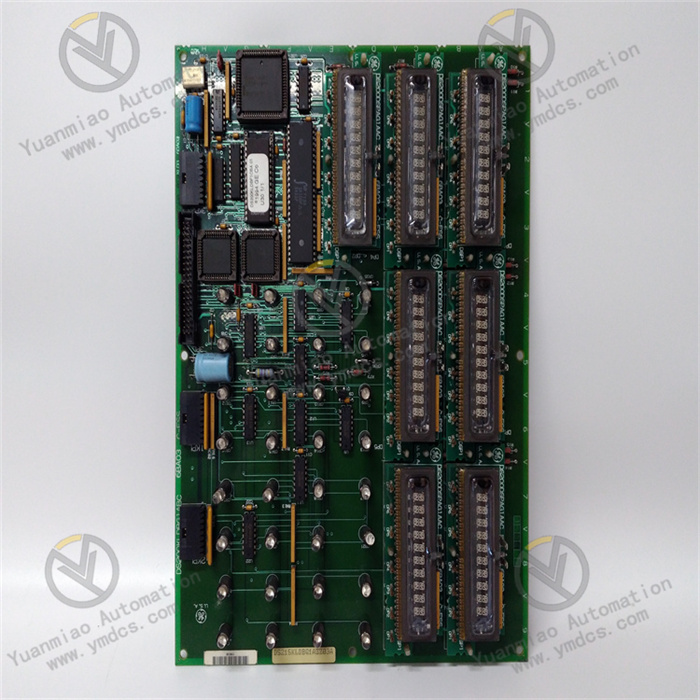

GE IC693TCM302

GE IC693TCM302 is a temperature control module positioned as an industrial-grade high-precision multi-loop temperature closed-loop control unit. With core advantages including 8 independent temperature control loops, multi-type sensor adaptation, and rich control algorithms, this product is specifically designed to provide accurate and stable temperature control functions for RX3i series PLC systems. It is compatible with industrial scenarios requiring strict temperature control precision and reliability, such as plastic molding, food processing, metallurgical heat treatment, and electronic welding. Its core value lies in realizing synchronous and precise control of multi-station temperatures through independent loop control and intelligent algorithm optimization, while featuring comprehensive fault diagnosis and alarm functions, providing key technical support for the stability of temperature parameters in industrial production processes.

I. Technical Parameters

1. Input Signal Parameters

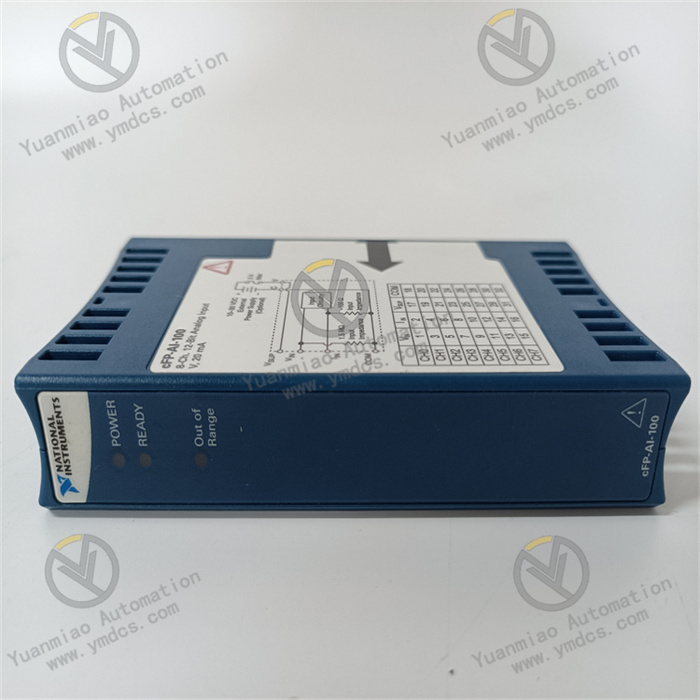

- Equipped with 8 independent analog input channels, supporting access to multi-type temperature sensor signals, including thermocouples (Types J, K, T, E, R, S, B, N), thermal resistors (Pt100, Cu50, Cu100), and standard analog signals (0-10V DC, 4-20mA DC). The sensor type can be flexibly configured via software according to on-site requirements without hardware jumper switching.

- Thermocouple input adopts cold junction compensation technology with a compensation accuracy of ±0.5℃. Thermal resistor input supports 2-wire, 3-wire, and 4-wire connection methods, effectively suppressing measurement errors caused by lead resistance. The measurement accuracy is improved by 20% with 3-wire connection.

- Each input channel is equipped with overvoltage protection, capable of withstanding continuous ±30V DC overvoltage, avoiding module damage caused by incorrect sensor wiring.

2. Output Control Parameters

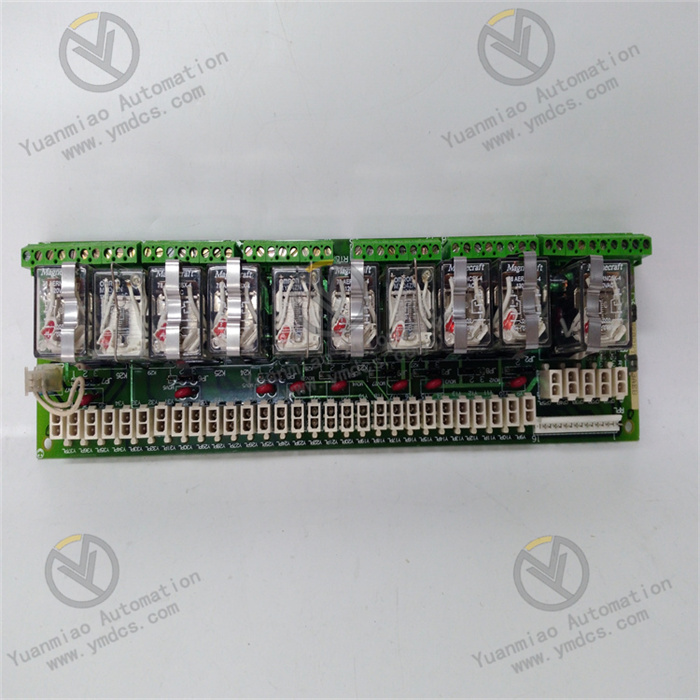

- Provides 8 independent control output channels, supporting three output types: relay output (250V AC/2A resistive load), transistor PWM output (24V DC/1A), and analog output (4-20mA DC or 0-10V DC). Each output type can be independently configured to adapt to different actuators such as heating tubes, solid-state relays (SSR), and variable-frequency heaters.

- PWM output frequency is software-adjustable within the range of 1Hz-1kHz, with a minimum output pulse width of 1ms, realizing precise power regulation. Analog output accuracy is ±0.1%FS, ensuring linear stability of actuator output.

- Supports output short-circuit protection. When a short circuit occurs at the output terminal, the module can cut off the output and alarm within 10ms.

3. Temperature Control Precision and Algorithm Parameters

- Adopts a 16-bit high-precision ADC converter, with a temperature measurement accuracy of ±0.1℃ (using Pt100 sensor within 0-100℃ range) and a full-scale measurement error of ≤±0.2%FS.

- Built-in multiple mature temperature control algorithms, including standard PID, auto-tune PID, fuzzy PID, and segmental PID, which can be flexibly selected according to the characteristics of the controlled object (e.g., large lag, nonlinearity).

- The auto-tune PID function can complete system identification within 30 seconds, automatically optimizing proportional (P), integral (I), and derivative (D) parameters, with a temperature control fluctuation range of ≤±0.5℃ (in steady state).

- Both the resolution of the temperature set value (SV) and measured value (PV) is 0.1℃, meeting high-precision temperature control requirements.

4. Structural and Hardware Parameters

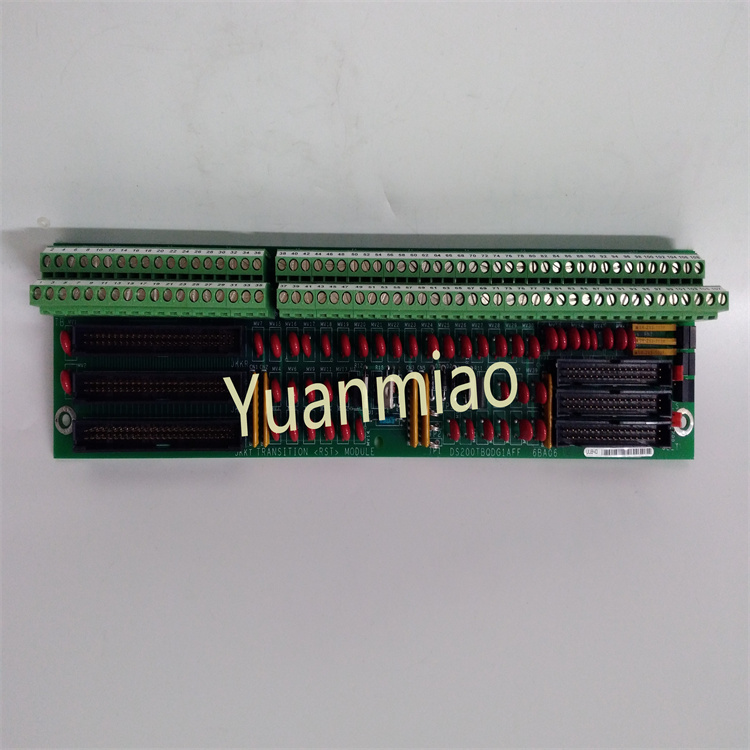

- Features a dual-slot design, compatible with RX3i series standard backplane installation. Module dimensions: 68mm×145mm×140mm, weight approximately 600g, with a compact structure and easy installation.

- The front panel is equipped with 8 groups of status LED indicators (each loop corresponds to PV normal, SV running, output active, and fault alarm indicators), providing intuitive feedback on the measurement status, control status, and fault information of each loop.

- Equipped with detachable spring-loaded terminal blocks, supporting 12-22AWG wire connection, which is firm and vibration-resistant, adapting to complex industrial on-site environments.

5. Environmental and Reliability Parameters

- Complies with industrial-grade wide-temperature operation standards: operating temperature range -25℃~+60℃, storage temperature range -40℃~+85℃, suitable for outdoor cabinets in cold regions and high-temperature workshop environments.

- Relative humidity adaptation range: 5%~95% (non-condensing), meeting the requirements of high-humidity food processing workshops, dusty metallurgical plants, and other scenarios.

- Certified by multiple international standards including CE, UL, and CSA, supporting Class I, Division 2 hazardous area installation. The Mean Time Between Failures (MTBF) is ≥250,000 hours, ensuring extremely high operational reliability.

6. Diagnosis and Alarm Parameters

- Equipped with full-loop diagnosis function, capable of detecting fault types such as sensor open circuit, short circuit, type mismatch, cold junction compensation fault, and output short circuit/overload, with a fault diagnosis coverage rate of ≥95%.

- Supports 8 independent alarm outputs (configurable as upper limit alarm, lower limit alarm, deviation alarm, and rate alarm), with an alarm response time of ≤100ms.

- Fault and alarm information can be uploaded to the RX3i controller in real-time via the backplane bus, and the front LED indicators will flash to alarm, facilitating quick problem location.

II. Key Features

1. 8 Independent Loops + Flexible Output, High Multi-Station Control Efficiency

- Core highlight: 8 fully independent temperature control loop designs. Each loop can be independently configured with sensor type, control algorithm, output type, and alarm parameters, enabling simultaneous temperature control of 8 independent stations.

- Compared with single-loop temperature control modules, the equipment integration is increased by 8 times, and the cabinet installation space is reduced by 70%.

- Each output supports independent selection of three types (relay, PWM, analog). For example, loops 1-4 can be configured as PWM output to drive SSR for heating tube control, and loops 5-8 as analog output to drive variable-frequency cooling systems, realizing collaborative control of heating and cooling and adapting to complex temperature control scenarios.

2. Multi-Sensor Adaptation + Precise Measurement, Strong Scene Compatibility

- Supports multi-type inputs such as thermocouples, thermal resistors, and standard analog signals, enabling direct access to temperature sensors of different brands and models without additional signal converters, reducing sensor adaptation costs by 40%.

- Thermocouple input adopts a high-precision cold junction compensation chip with a compensation error of ±0.5℃, solving the problem of low precision in traditional cold junction compensation.

- Thermal resistor 3-wire/4-wire connection support effectively offsets the impact of lead resistance on measurement. In scenarios with 100m long wires, the measurement error can be controlled within ±0.2℃, which is far superior to the traditional 2-wire connection scheme.

3. Intelligent PID Algorithm + Auto-Tune Function, Dual Advantages of Temperature Control Precision and Adaptability

- Built-in multiple algorithms including standard PID, auto-tune PID, and fuzzy PID. Standard PID is suitable for conventional linear controlled objects; fuzzy PID targets large-lag and nonlinear scenarios such as plastic molding, dynamically adjusting PID parameters through fuzzy logic, reducing the temperature control fluctuation range to ±0.3℃.

- The auto-tune function can automatically identify the thermal inertia, response speed, and other characteristics of the controlled object, completing parameter optimization within 30 seconds. Compared with manual debugging, the debugging efficiency is improved by 90%, and the problem of insufficient temperature control precision caused by insufficient manual experience is avoided.

- Supports segmental PID function, allowing different PID parameters to be set for heating, heat preservation, and cooling stages, adapting to multi-stage temperature control requirements such as electronic welding.

4. Full-Dimensional Diagnosis + Multi-Type Alarm, Significantly Improved Operation and Maintenance Efficiency

- Integrates full-dimensional diagnosis functions for sensor faults, output faults, power supply faults, etc., capable of accurately locating fault loops and fault types (e.g., open circuit of Pt100 sensor in loop 3).

- Fault information is uploaded via LED indicators and the backplane bus, and detailed fault information can be intuitively displayed through the HMI interface, reducing troubleshooting time to within 5 minutes and improving operation and maintenance efficiency by 80% compared with traditional temperature control modules.

- Supports four alarm types: upper limit, lower limit, deviation, and rate. For example, setting a deviation alarm (alarm when the deviation between PV and SV exceeds ±2℃) can promptly detect temperature control abnormalities, avoiding product scrapping caused by excessive temperature. The alarm history can store 100 fault records, facilitating traceability of fault causes.

5. Convenient Configuration + Data Interaction, Reduced Integration Costs

- Graphical configuration of each loop's parameters (sensor type, output type, PID parameters, alarm threshold) can be performed via GE Proficy Machine Edition software, supporting batch parameter copying. The configuration time for 8 loops is shortened to within 10 minutes.

- Supports online parameter modification and real-time monitoring of each loop's PV, SV, and output status, enabling parameter adjustment without shutdown.

- The module communicates with the controller at high speed via the RX3i backplane bus, with a data update cycle of ≤100ms. It can upload 8 channels of temperature control data to the SCADA system, realizing centralized monitoring and historical traceability of temperature parameters without additional communication modules, reducing integration costs by 30%.

III. Working Principle and Applications

3.1 Working Principle

GE IC693TCM302 realizes closed-loop temperature control based on the core logic of "temperature collection → signal processing → algorithm calculation → control output → diagnosis and alarm". The specific process is as follows:① Temperature Collection Stage: Access sensor signals (e.g., Pt100 thermal resistor signals) through 8 independent input channels. Thermocouple input requires cold junction compensation circuit to correct the impact of ambient temperature, while thermal resistor input uses constant current source excitation and signal amplification circuit to improve measurement precision.② Signal Processing Stage: The 16-bit ADC converter converts analog sensor signals into digital signals, and filter algorithms are used to eliminate signal fluctuations caused by electromagnetic interference, outputting stable temperature measured values (PV).③ Algorithm Calculation Stage: Compare PV with the preset temperature set value (SV), calculate the control quantity through the selected PID algorithm (e.g., auto-tune PID), and dynamically adjust the output amplitude according to the state of the controlled object.④ Control Output Stage: Based on the algorithm calculation results, drive actuators (e.g., heating tubes, cooling valves) through relay, PWM, or analog output channels to adjust the temperature of the controlled object.⑤ Diagnosis and Alarm Stage: Real-time monitor the integrity of sensor signals, output load status, and module power supply. When an abnormality is detected (e.g., sensor open circuit, output short circuit), immediately cut off the output and trigger an alarm, while uploading fault information to the controller, forming a complete temperature control-diagnosis closed loop.

3.2 Application Scenarios

- Temperature Control for Plastic Injection Molding: In the temperature control system of plastic injection molding machines, the IC693TCM302 module accesses 8 channels of Pt100 thermal resistors (3-wire connection) to monitor the temperatures of 8 sections of the injection molding machine barrel respectively. The output adopts PWM type to drive solid-state relays (SSR) for heating coil control. Through the auto-tune PID algorithm, the steady-state fluctuation of each section's temperature after auto-tuning is ≤±0.5℃, and the temperature uniformity of each section of the barrel is improved by 15%. A deviation alarm is set (alarm when the deviation between PV and SV is ≥1℃). When a heating coil in a certain section fails, the module alarms and cuts off the output within 100ms, avoiding plastic carbonization caused by local overheating of the barrel. The module uploads 8 sections of temperature data to the RX3i controller via the backplane bus, and cooperates with the HMI to realize centralized monitoring and historical curve query of temperature parameters, improving product qualification rate by 5%.

- Temperature Control for Food Baking Ovens: In the temperature control system of ovens in food baking production lines, the IC693TCM302 module is configured with 4 channels of K-type thermocouples (monitoring the temperatures of the upper, lower, left, and right areas of the oven) and 4 channels of analog outputs (driving variable-frequency cooling fans), adopting the fuzzy PID algorithm to cope with the large lag characteristics of the oven. During the heating stage, the relay output drives the heating tube to quickly raise the temperature; during the heat preservation stage, the analog output adjusts the speed of the cooling fan, realizing a temperature fluctuation of ≤±0.3℃ inside the oven and ensuring uniform taste of baked food. A rate alarm is set (alarm when the temperature rise rate exceeds 5℃/min) to avoid surface scorching of food caused by excessive heating speed of the oven. The module supports Class I, Division 2 hazardous area installation, adapting to the high-temperature and high-humidity environment of baking workshops, with an annual operational reliability of 99.99%.

- Temperature Control for Metallurgical Heat Treatment Furnaces: In the temperature control system of heat treatment furnaces for steel parts, the IC693TCM302 module accesses 8 channels of S-type thermocouples (measuring high temperatures at different positions in the furnace, range 0-1600℃), and the output adopts relay type to control silicon carbide rod heaters, using the segmental PID algorithm (heating stage: P=50, I=100, D=10; heat preservation stage: P=30, I=200, D=5). The heating stage quickly reaches the set value of 1200℃, and the temperature fluctuation during the heat preservation stage is ≤±1℃, ensuring uniform quenching hardness of parts. The sensor open circuit diagnosis function of the module can quickly locate broken thermocouples, avoiding part scrapping caused by temperature measurement failure. 8 channels of temperature data are centrally monitored through the SCADA system, generating heat treatment process curves to meet the process traceability requirements of the metallurgical industry.

- Temperature Control for Electronic Component Welding: In the temperature control system of reflow ovens in PCB welding production lines, the IC693TCM302 module is configured with 8 channels of Pt100 thermal resistors to monitor the temperatures of the preheating zone, heating zone, welding zone, and cooling zone of the reflow oven. The output adopts PWM type to drive heating tubes and cooling fans, and the auto-tune PID algorithm is used to realize precise temperature control of each zone. The preheating zone temperature is stabilized at 150℃±0.5℃, the welding zone at 250℃±0.5℃, and the cooling zone at 80℃±0.5℃, ensuring firm welding of electronic components without false welding. The alarm history recording function can store nearly 100 temperature exceeding records, facilitating the analysis of the correlation between welding defects and temperature abnormalities, and improving the welding qualification rate by 8%.

IV. Common Faults and Troubleshooting

1. Fault 1: Abnormal Temperature Measurement Value (Inaccurate or Fluctuating PV Display)

- Possible Causes: Incorrect sensor type configuration, loose or damaged sensor wiring, cold junction compensation fault (thermocouple input), excessive lead resistance (thermal resistor input), electromagnetic interference.

- Troubleshooting Measures:① Log in to the configuration software to verify the sensor type configuration (e.g., K-type thermocouple mistakenly configured as J-type) and reconfigure the correct type.② Check the tightness of sensor terminal connections and replace damaged sensor cables.③ For thermocouple input, check if the cold junction compensation resistor is normal and replace the compensation chip if faulty.④ Use 3-wire or 4-wire connection for thermal resistors and replace with thicker wires (e.g., 16AWG) to reduce lead resistance.⑤ Install the module away from strong interference equipment such as frequency converters, or add a shielding layer to the sensor cable and ground it reliably.

2. Fault 2: No Control Output Action (Output Indicator Not Lit)

- Possible Causes: Incorrect output type configuration, loose output terminal wiring, actuator fault, module protection caused by output loop short circuit, improper PID parameter setting (e.g., output limited to 0).

- Troubleshooting Measures:① Verify the output type configuration in the configuration software (e.g., PWM output mistakenly configured as relay output) and reconfigure.② Check the output terminal wiring to ensure firm connection with the actuator.③ Power on the actuator independently to test and confirm that the actuator is free of faults.④ Disconnect the actuator and measure the voltage/current at the module output terminal. If it returns to normal, the actuator is short-circuited, and the actuator should be replaced.⑤ Check the output upper limit setting in the PID parameters to ensure it is not mistakenly set to 0, and execute the auto-tune function to re-optimize the parameters.

3. Fault 3: Temperature Cannot Reach Set Value (PV Always Lower Than SV)

- Possible Causes: Insufficient heating power, actuator fault (e.g., damaged heating tube), improper PID parameters (too small P value, too large I value), improper sensor installation position, excessive environmental heat dissipation.

- Troubleshooting Measures:① Calculate whether the heating power matches the controlled object and increase the number of heating tubes if insufficient.② Detect the resistance value of the heating tube to confirm no damage and replace if faulty.③ Increase the P value and decrease the I value in the PID parameters, or execute the auto-tune function to re-optimize.④ Adjust the sensor installation position to ensure it is close to the controlled area (e.g., inside the barrel rather than the surface).⑤ Add an insulation layer to the controlled object to reduce environmental heat dissipation.

4. Fault 4: Excessively Large Temperature Fluctuation (PV Fluctuates Significantly Around SV)

- Possible Causes: Improper PID parameters (too large P value, too small D value), excessively fast actuator response speed, measurement signal interference, too small thermal inertia of the controlled object.

- Troubleshooting Measures:① Decrease the P value and increase the D value in the PID parameters, or switch to the fuzzy PID algorithm.② Reduce the PWM output frequency (e.g., from 1kHz to 100Hz) or replace with an actuator with slower response speed.③ Add a shielding layer to the sensor cable and ensure the module ground resistance is ≤4Ω to suppress electromagnetic interference.④ Increase the thermal inertia of the controlled object (e.g., add an insulation sleeve to the small-capacity barrel).

5. Fault 5: Module Reports Sensor Fault (Fault Indicator Lit)

- Possible Causes: Sensor open circuit or short circuit, mismatch between sensor type and configuration, cold junction compensation fault (thermocouple input), module input channel fault.

- Troubleshooting Measures:① Use a multimeter to measure the sensor resistance or voltage, confirm that the sensor is free of open/short circuit, and replace if faulty.② Verify that the actual sensor type is consistent with the configuration software settings (e.g., Pt100 mistakenly configured as Cu50).③ For thermocouple input, check the cold junction compensation circuit and replace the faulty compensation chip.④ Connect the sensor of the faulty channel to a normal channel. If it returns to normal, the module input channel is faulty, and a spare module should be replaced.