Description

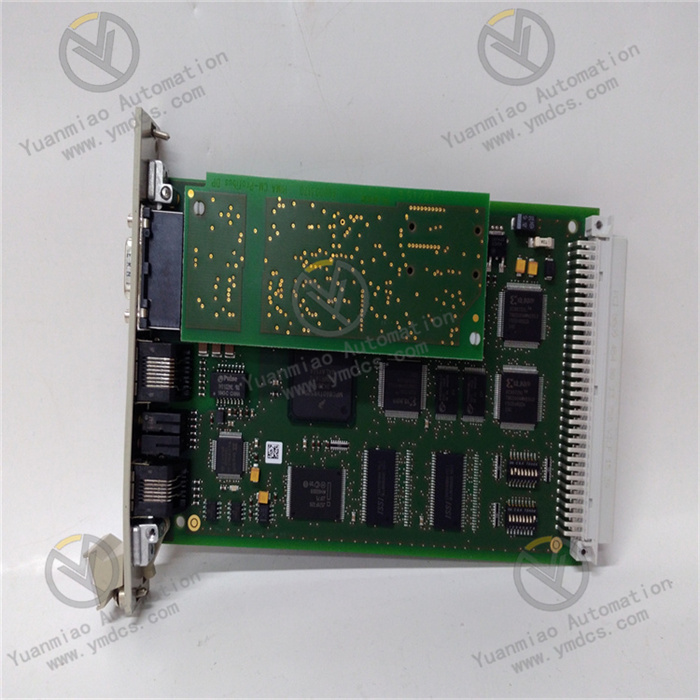

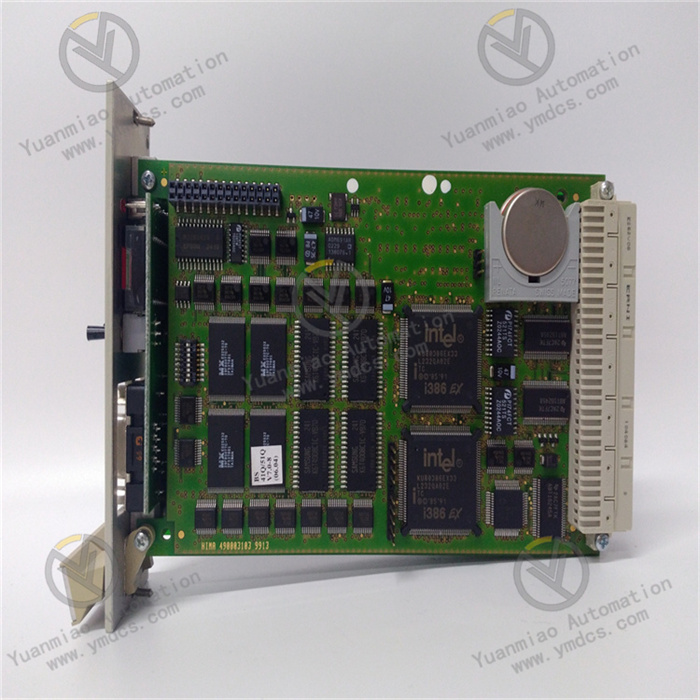

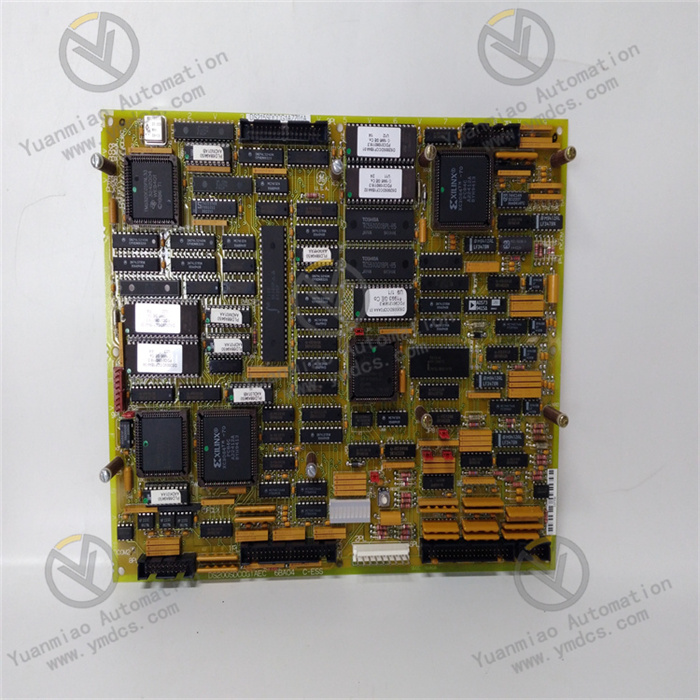

Triconex 4351B

The Triconex 4351B is a high-performance triplex safety controller module primarily used in industrial safety instrument systems (SIS), featuring high reliability, fault tolerance, and safety. It includes types such as digital input modules, expansion modules, and enhanced intelligent communication modules. As a digital input module, it connects digital sensors and actuators, providing 16 digital input ports that can interface with various sensors like switches, buttons, and relays, and supports multiple input modes.

Features:

- Triplex Redundancy Architecture (TMR)

- Hardware Redundancy Design: Utilizes a Triple Modular Redundancy (TMR) architecture with three independent processors, memories, and I/O channels. Through a built-in voting mechanism (majority voting or 2oo3 mode), it ensures single-point failures do not affect normal system operation.

- High Fault Tolerance: Enables online replacement of faulty modules (hot-swappable) and supports "non-stop" continuous operation, suitable for scenarios requiring extremely high availability (e.g., petrochemical, nuclear power, large industrial plants).

- High Safety and Reliability

- Compliance with Safety Standards: Certified to international safety standards (e.g., IEC 61508 SIL 3, ISA 84.00.01, EN 50155) and applicable to SIL 3-level safety systems.

- Self-Diagnosis: Equipped with comprehensive self-diagnostic functions to monitor hardware and software status in real time, with a diagnostic coverage (DC) rate exceeding 99% to reduce potential risks.

- Anti-Interference Capability: Designed for electromagnetic compatibility (EMC) to resist electromagnetic interference (EMI), radio-frequency interference (RFI), and voltage transients in industrial environments.

- High-Performance Processing

- Multi-Core Processor: Features high-speed processors supporting complex logical operations and real-time control, with fast processing speeds to meet high-speed data acquisition and rapid response requirements.

- Flexible Programming Environment: Supports multiple industrial standard programming languages (e.g., ladder logic, ST, CFC) and is programmed and configured via Triconex-specific software (e.g., TriStation), offering a user-friendly and powerful interface.

- Rich Communication and Expansion Capabilities

- Multiple Communication Interfaces: Supports Ethernet (EtherNet/IP, Modbus TCP), serial ports (RS-232/485), fieldbuses (e.g., Profibus, CANopen), etc., for easy integration with host computers, PLCs, DCS systems, or third-party devices.

- Modular Expansion: Can connect to various I/O modules (e.g., digital, analog, pulse) via expansion racks, adapting to system configurations of different scales and supporting distributed architectures.

- Industrial-Grade Design and Usability

- Wide Operating Range: Suitable for harsh industrial environments (e.g., high temperature, high humidity, vibration), with an operating temperature range typically from -40°C to +70°C, meeting outdoor or stringent indoor environment requirements.

- Convenient Maintenance and Diagnosis: Equipped with LED status indicators for online monitoring and fault localization; supports remote configuration and firmware upgrades to minimize downtime.

- Compact Installation: Uses rail mounting to save cabinet space and supports high-density integration.

- Application Scenarios

Mainly used in safety-critical systems, such as: - Emergency Shutdown Systems (ESD)

- Fire and Gas Detection and Control Systems (F&G)

- Compressor Surge Control

- Turbine Protection Systems

- Nuclear Power Plant Safety Systems

Conclusion:

The Triconex 4351B, with its triplex redundancy, high safety certification, powerful processing capabilities, and flexible scalability, has become one of the mainstream controllers in the industrial safety field, particularly suitable for large complex systems with extremely high reliability and safety requirements. Its core design philosophy is to minimize system failure probabilities through hardware redundancy and advanced diagnostic technologies, ensuring the safety of personnel, equipment, and the environment.

Technical Parameters:

Communication Functions:

- Supports bidirectional communication with Triconex systems 10.3 and above.

- Performs data mapping from TRICON memory tables to EUCN formats, converting data into EUCN data types (tags, parameters), engineering units, and EUCN communication functions.

- Reads from and writes to TRICON memory tables, defining signal alarm conditioning, message transmission for alarm handling and notifications, and diagnostic status reporting on EUCN.

- Enables direct peer-to-peer communication with other EUCN-connected devices, such as Enhanced High-Performance Process Managers (EHPM) and Enhanced Logic Managers (ELMM).

Hardware Installation Types:

- Front and rear cabinet access installation (MC-ZTCMIR or MC-TCMIR1).

- Front-only cabinet access installation (MC-ZTCMI2 or MC-TCMIR2).

Other:

- TCMI directly connects to the Ethernet port security manager of the Tricon Communication Module (TCM) in Tricon. TCM implements the TSAA communication protocol over Ethernet for communication with Tricon controllers.

- TCMI requires a pair of TCMs (two units, part numbers 4351A and 4351B) in the Triconex system. TCMs connected to TCMI must be located in a single Triconex system logic slot and occupy left and right module physical slots (including a single logic slot). At least one port on each TCM needs to configure redundant TCMI pairs.

Application Cases:

- Petrochemical Industry

- Emergency Shutdown System (ESD): In petrochemical production units, the Triconex 4351B connects the digital signals of various switch-type sensors (e.g., pressure switches, temperature switches, level switches) to the safety instrument system's controller. For example, when the pressure in a reactor exceeds safe limits, the pressure switch activates, and the 4351B rapidly transmits the signal to the ESD system, which triggers an emergency shutdown sequence to close relevant valves, pumps, and other equipment, preventing accidents.

- Fire and Gas (F&G) Monitoring System: In petrochemical plants, the 4351B receives digital signals from flame detectors, combustible gas detectors, and other devices. Upon detecting fire or gas leaks, the module immediately transmits alarm signals to the F&G system's controller, which activates corresponding fire-fighting equipment (e.g., sprinkler systems, gas suppression systems) and issues evacuation alerts.

- Power Industry

- Turbine Protection System: In power plants, the 4351B monitors various status signals of turbines, such as overspeed protection switches, axial displacement protection switches, and vibration protection switches. When abnormal conditions occur (e.g., excessive speed, axial displacement, or vibration), the corresponding protection switches activate, and the 4351B transmits signals to the turbine protection system's controller, which rapidly issues trip commands to shut down the turbine and avoid equipment damage or accident escalation.

- Generator Protection System: The 4351B connects to the output signals of generator differential protection, overcurrent protection, and ground fault protection relays. When internal or external faults threaten the generator's safe operation, the relevant protection relays activate, and the 4351B transmits fault signals to the generator protection system's controller, which implements corresponding protection measures (e.g., tripping the generator outlet breaker, activating the de-excitation device) to safeguard the generator and power system stability.

- Metallurgical Industry

- Blast Furnace Safety Control System: During blast furnace operations, the 4351B monitors key parameters and equipment status (e.g., top pressure switches, cooling water flow switches, material level switches). When top pressure deviates from safe ranges, cooling water flow is abnormal, or material levels are irregular, the module transmits relevant digital signals to the blast furnace safety control system's controller, which adjusts top gas bleeder valves, starts standby cooling pumps, or halts the charging system to ensure furnace safety.

- Converter Tilting Safety System: In converter steelmaking, the 4351B monitors limit switches of the converter tilting mechanism and status signals of braking devices. When the converter tilts to extreme positions or braking device failures occur, the module transmits signals to the converter tilting safety system's controller, which immediately stops the tilting motor and issues alarms to prevent converter overturning accidents.

Other Brand-Related Products