Description

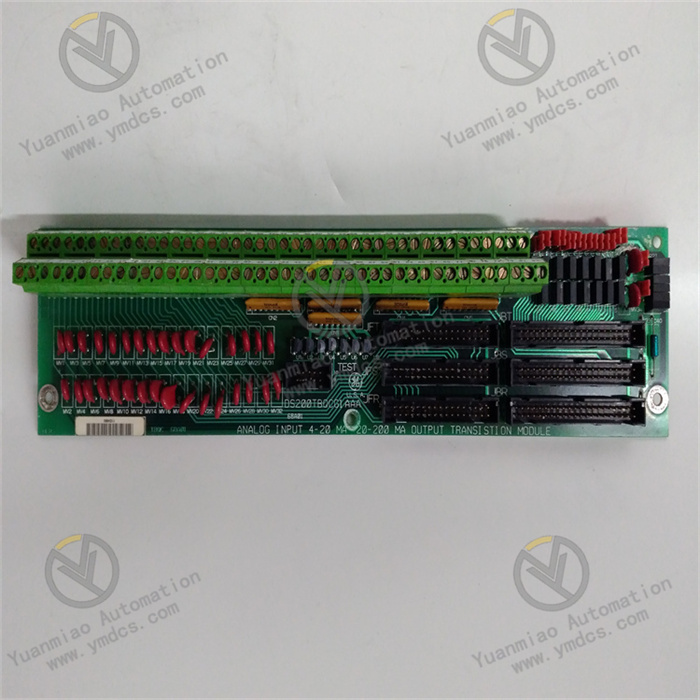

GE DS200TBQDG1AFF

I. Overview

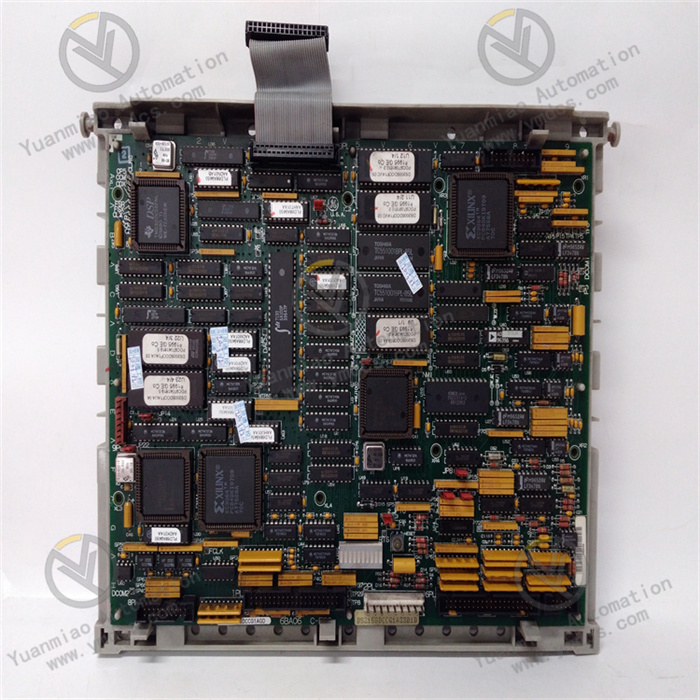

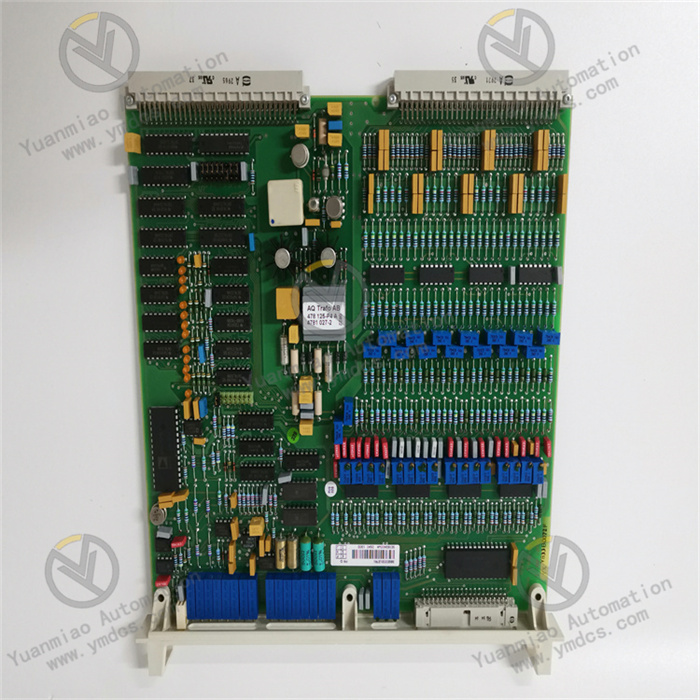

The GE DS200TBQDG1AFF is an excellent extended analog terminal board that plays a pivotal role in industrial automation. Belonging to GE's classic MARK V series, it is tailor-made for complex industrial environments with extremely high stability requirements. As a crucial expansion board for the RST (Remote Slave Terminal) system, its core mission is to add extra analog input and output channels, significantly enhancing the system's capability to connect analog sensors and actuators. This feature enables its wide application in industrial automation, making it a reliable assistant for the stable operation of many key industrial systems.

In the power industry, the DS200TBQDG1AFF plays a key role in both precise measurement and control of operating parameters (such as temperature, pressure, flow, etc.) of various equipment in the power generation link and real-time monitoring and regulation of key indicators in transmission and distribution systems. By accurately collecting and processing analog signals, it ensures the stable and efficient operation of power systems, providing reliable power support for social production and daily life. In the petrochemical industry, every link from oil refining to chemical product production involves numerous complex physical and chemical reaction processes, requiring strict control of parameters like temperature, pressure, and liquid level. The DS200TBQDG1AFF can precisely process analog signals corresponding to these parameters, assisting petrochemical enterprises in achieving safe and efficient production, reducing energy consumption, and minimizing environmental pollution. In the metallurgical industry, production processes such as blast furnace ironmaking, converter steelmaking, and steel rolling also rely on precise monitoring and control of key parameters like temperature and pressure. This device provides solid support for the stable operation of metallurgical production processes through effective analog signal processing, helping improve product quality, reduce production costs, and enhance production efficiency. Additionally, in fields such as gas turbine control systems, industrial automation production lines, process control, and laboratory testing, the DS200TBQDG1AFF plays an indispensable role with its excellent performance and reliability, driving the continuous improvement of automation levels across industries.

II. Technical Parameters

Power Parameters

- Voltage: The operating voltage is 24VDC. This DC power supply mode has wide applicability in industrial applications, enabling good matching with most industrial power systems and providing reliable power support for the stable operation of the device.

- Power Consumption: The device features low power consumption, effectively reducing energy consumption. In long-term operation, it helps enterprises save electricity costs, aligning with the current green and energy-saving industrial development concept.

Electrical Parameters

- Input Range: It can receive input signals ranging from -10V to +10V. Such a broad input range allows it to adapt to the access of output signals from various analog sensors, greatly improving the device's versatility and facilitating flexible application in different industrial scenarios.

- Output Range: The output signal range is also -10V to +10V, capable of providing precise analog signals that meet the working requirements of subsequent connected actuators, ensuring the accuracy of signal transmission and control in the entire industrial control system.

- Accuracy: With a sampling accuracy of up to 0.1%, it can extremely accurately convert analog signals into digital signals during the signal collection and processing process, providing high-precision data support for the system. This is of great significance for industrial application scenarios with extremely high measurement accuracy requirements, such as precision instrument manufacturing and high-end chemical production.

- Isolation Voltage: It has an isolation voltage of 2500Vrms, effectively achieving electrical isolation between input and output, as well as between the device and external circuits. This can largely prevent external interference signals from affecting the internal circuits of the device, while also avoiding interference generated by the device itself from affecting other equipment, improving the device's anti-interference capability and operational stability in complex electromagnetic environments.

Communication Parameters

- Communication Interface: Equipped with an RS485 communication interface, which is widely used in industrial communication for its advantages of long transmission distance and strong anti-interference capability. Through the RS485 interface, the DS200TBQDG1AFF can conveniently and stably communicate data with other devices. Whether connected to a host computer control system or forming an industrial automation network with other intelligent devices, it can achieve efficient data interaction to ensure the collaborative operation of the entire system.

Other Parameters

- Number of Channels: It has 8 analog input/output channels and features expandability, allowing flexible increase in the number of channels according to actual industrial application requirements. This meets the requirements of different-scale industrial control systems for the number of analog signal processing channels, providing convenience for system upgrading and expansion.

- Operating Temperature Range: It can stably operate in the temperature range of -10°C to 50°C, adapting to the temperature conditions of most industrial environments. Whether in outdoor industrial facilities in cold regions or production workshops in high-temperature environments, it can operate normally to ensure the continuous and stable operation of the system.

- Protection Level: The protection level reaches IP20, which can effectively prevent solid foreign objects larger than 12mm from entering the device, providing a certain protective effect on the internal electronic components, reducing the risk of device failure caused by foreign object intrusion, and improving the device's reliability in general industrial environments.

- Dimensions: The external dimensions are 120mm x 60mm x 25mm. The compact design gives it obvious advantages in installation environments with limited space, such as industrial control cabinets, facilitating flexible layout and installation and saving valuable installation space.

- Weight: It weighs only 0.2kg. The light weight facilitates the installation, handling, and maintenance of the device, reducing the difficulty and labor intensity of manual operations.

III. Functional Features

High Expandability

It can flexibly expand the number of analog input/output channels according to actual industrial control needs. When facing industrial automation projects with expanding scales and increasingly complex control requirements, there is no need to replace the entire system. Simply increasing the number of DS200TBQDG1AFF or expanding their channels can easily meet the new analog signal connection and processing needs, saving system upgrade costs for enterprises and improving the system's adaptability and expandability.

High-precision Signal Processing

With a high-precision sampling capability of 0.1%, it can accurately restore the true value of analog signals during collection and processing. In industrial applications with strict measurement accuracy requirements, such as precise control of reaction temperature and pressure in the pharmaceutical industry and precise monitoring of process parameters in semiconductor manufacturing, it provides accurate and reliable data foundations for the system, ensuring product quality stability and consistency, effectively reducing defective rates, and improving enterprises' economic benefits.

High Reliability

Manufactured with industrial-grade high-quality components, these components undergo strict screening and testing, featuring excellent stability and durability. In the complex and changeable industrial field environments, such as those with strong electromagnetic interference, high humidity, and heavy dust, it can still operate stably, effectively reducing device failure rates, minimizing production downtime caused by device failures, ensuring the continuity of industrial production, and improving enterprise production efficiency. Meanwhile, its good anti-interference design and electrical isolation measures further enhance the device's reliability in complex electromagnetic environments, ensuring the accuracy and stability of signal transmission.

Modular Design

The entire device adopts a modular design concept, where each functional module works independently yet collaboratively. This design makes device installation, maintenance, and fault troubleshooting more convenient. When a module fails, technicians can quickly locate and replace the corresponding module without large-scale maintenance of the entire device, greatly shortening device downtime and reducing maintenance costs. At the same time, modular design also facilitates device upgrading and optimization, allowing enterprises to flexibly replace or add functional modules according to their needs to enhance device performance and functions.

Multifunctional Configuration

It has a flexible input/output range configuration function, allowing adjustment of the input/output range according to the signal characteristics of different analog sensors and actuators. Whether low-voltage signals, high-voltage signals, or different types of current signals, the device can be adapted to them through simple configuration operations, greatly improving the device's versatility and applicability in different industrial scenarios and facilitating enterprises' use in diversified industrial control projects.

Convenient Diagnosis and Operation

Equipped with multiple test points (such as TP1, TP2, TP3), qualified service personnel can use these points to comprehensively detect each circuit of the device, facilitating quick location of device faults. Meanwhile, if the testing instrument does not identify clear issues, in-depth troubleshooting can be carried out with the diagnostic tools provided by the driver. The device features a user-friendly operation interface. Through the keyboard on the driver, operators can easily access diagnostic tools to achieve real-time monitoring and adjustment of the device's operating status, such as stopping or starting the motor, changing the motor's direction and speed, etc., reducing device operation difficulty and improving work efficiency.