Description

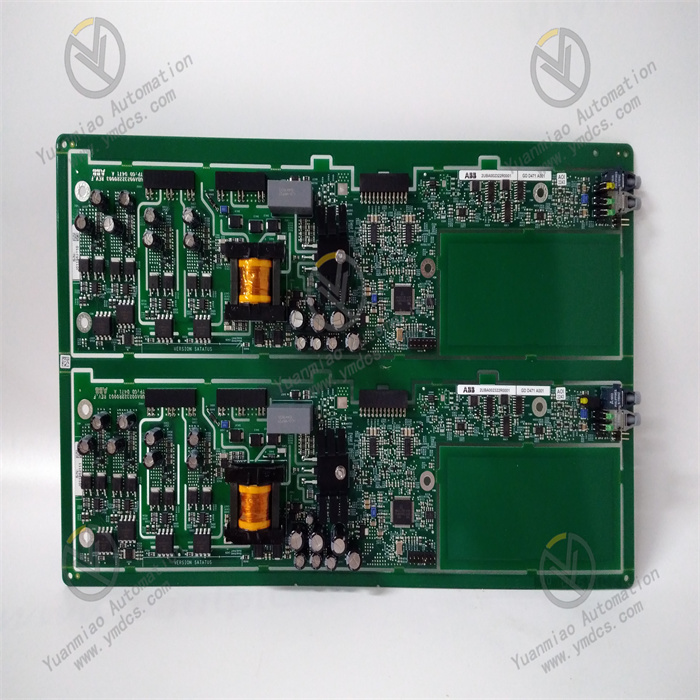

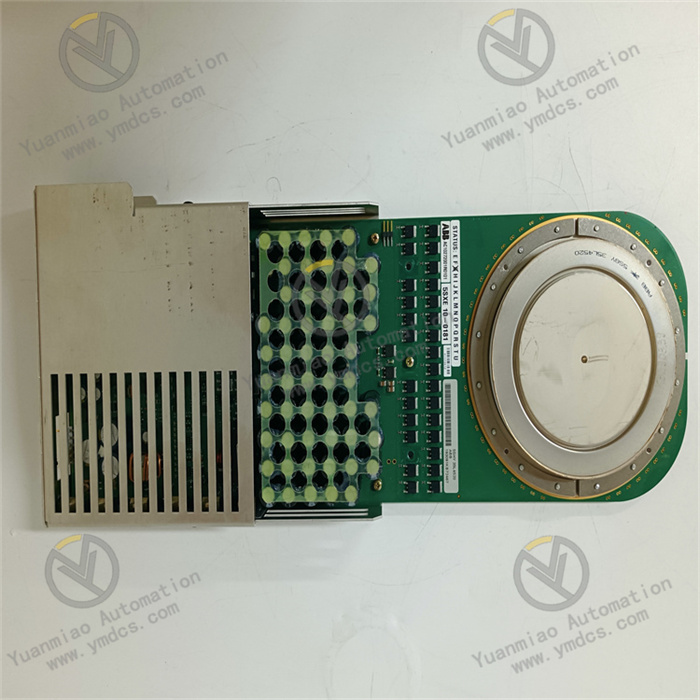

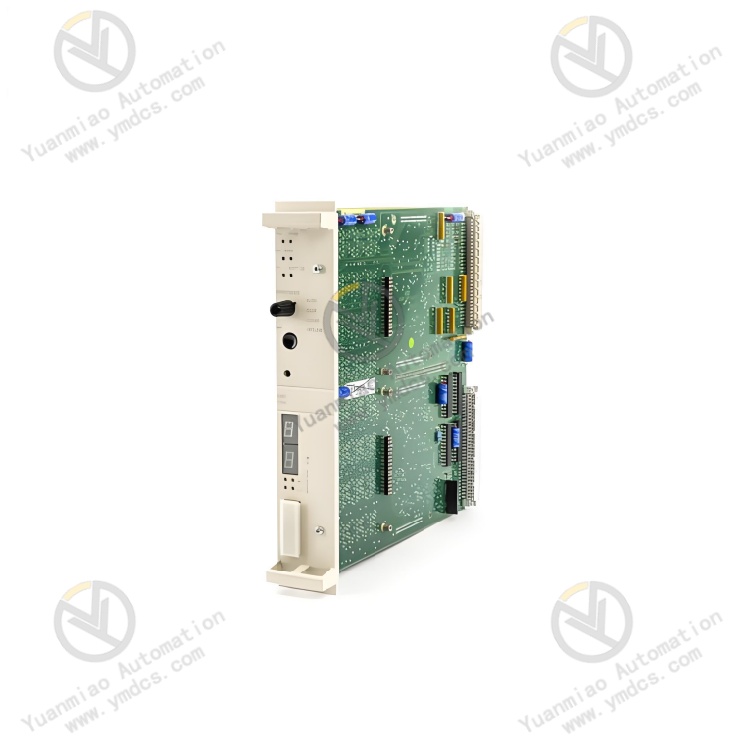

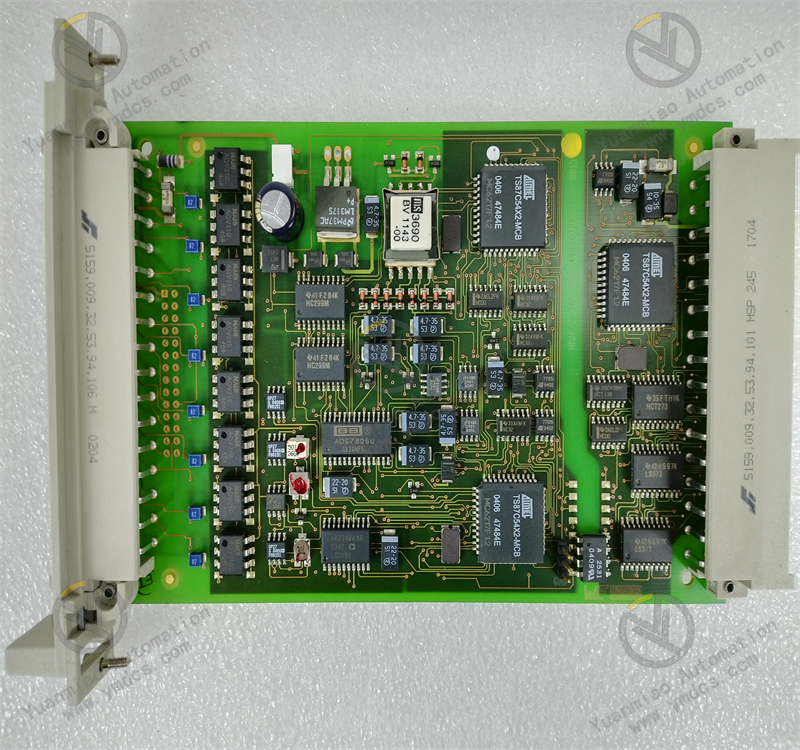

Functional Features: Analog Signal Processing: It can be used as an analog current source to output a stable analog current signal. At the same time, it can receive and process analog input signals, which helps to accurately control and monitor relevant electrical parameters. High-voltage Insulation and Voltage Control: It has the ability of high-voltage insulation and can withstand high voltage levels to ensure safe operation in a high-voltage environment. Meanwhile, it has precise voltage control ability, which can effectively control and distribute high voltage, ensuring the stability and reliability of the electrical system. Gate Signal Control: As a gate control board, it is responsible for managing the gate signals of power electronic devices (such as IGBTs or thyristors), ensuring the correct timing and sequence of the signals to control the operation of rectifiers and inverters, and optimizing the performance and reliability of the rectification process. Synchronization Function: It has a synchronization function, which can control the operation of the generator to synchronize it with other generators or the power grid in the power system. It ensures that the voltage, frequency, and phase parameters of the generator match those of the power system, enabling safe and reliable power transmission and generator grid connection. It is usually equipped with a variety of synchronization protection functions to protect the generator and the power system from potential faults and damages.

Technical Parameters: The operating voltage is generally 220V, and the output frequency is 80. However, there may be differences in different application scenarios and specific models. Application Fields: It is widely applied in various industrial automation fields that require analog current sources and high-voltage control, such as the power, petroleum, chemical, and metallurgical industries. In these fields, it is used to control and monitor various equipment in the production process to ensure the stability and efficiency of the production process. Design Features: It adopts a reliable and durable design, which can withstand harsh industrial environment conditions, reduce the probability of failures, and lower the maintenance cost. Moreover, it is easy to install and maintain.

How to detect the high-voltage insulation performance of GDB021BE05?

Appearance Inspection: Before conducting electrical detection, first conduct an appearance inspection of the GDB021BE05 control board. Check whether there are obvious damages, cracks, burnt marks, or signs of moisture on the surface of the circuit board, especially whether the insulation layer is damaged. These physical damages may affect the high-voltage insulation performance.

Insulation Resistance Test

Prepare the testing equipment: Use a high-resistance meter (insulation resistance tester) and ensure that its measuring range is suitable for measuring the insulation resistance of the control board. Generally, it should be able to measure at least several hundred megohms or even higher resistance values.

Connect the testing equipment: After the control board is powered off and fully discharged, connect the test probes of the high-resistance meter to the components or circuits whose insulation performance needs to be tested respectively. For example, connect between the high-voltage circuit and the grounding terminal, or between different high-voltage circuits.

Conduct the test: Perform the measurement according to the operation instructions of the high-resistance meter. Usually, a certain test voltage needs to be applied (such as 500V or 1000V DC voltage, which is specifically determined according to the specifications and requirements of the control board). Read and record the measured insulation resistance value. Generally speaking, a good insulation resistance value should be above several hundred megohms. The specific qualified standard can refer to the technical manual of the GDB021BE05 control board.

Withstand Voltage Test

Prepare the withstand voltage tester: Use a specialized withstand voltage tester and ensure that its output voltage range and capacity can meet the testing requirements of the control board.

Set the test parameters: According to the technical specifications of the control board, set appropriate test voltage and test time. The test voltage is usually a certain multiple higher than the normal operating voltage (such as 1.5 times or 2 times the rated operating voltage), and the test time is generally about 1 minute.

Connect the testing equipment: Connect the output terminal of the withstand voltage tester to the relevant test points of the control board. Also, pay attention to connecting between the high-voltage circuit and the grounding terminal or between different high-voltage circuits. Ensure that the grounding terminal of the testing equipment is reliably grounded.

Conduct the test: Start the withstand voltage tester, gradually raise the test voltage to the set value, and maintain the specified test time. During the test, observe whether the tester gives an alarm or trips, and at the same time, pay attention to whether there are discharges, flashovers, or other abnormal conditions on the control board. If the tester alarms or trips during the test, it indicates that there may be a problem with the insulation performance of the control board, and further inspection and analysis are required.

Partial Discharge Test (Optional): For some application scenarios with high requirements for insulation performance, a partial discharge test may be required. The partial discharge test can detect tiny defects or discharge phenomena inside the insulation material. These defects may gradually develop during long-term operation and eventually lead to insulation failure. The partial discharge test usually requires the use of a specialized partial discharge detector and should be carried out according to its operation instructions.

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage