Description

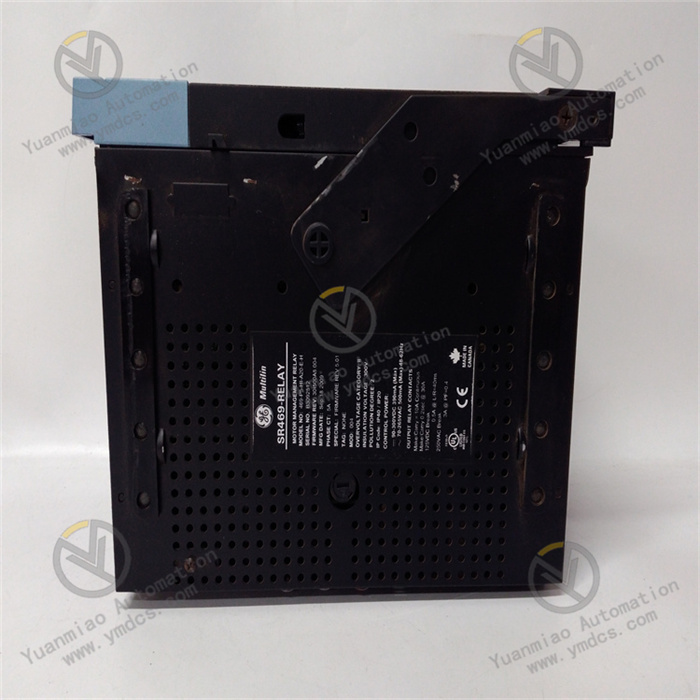

GE Multilin SR469-P1-LO-A20-E

I. Product Overview

The GE Multilin SR469-P1-LO-A20-E is an integrated motor protection relay specifically designed for medium-and high-voltage asynchronous motors, synchronous motors, and other rotating equipment. Positioned as an "intelligent protection and monitoring terminal for full operating conditions of large motors", its core function is to achieve full-lifecycle protection for motors during startup, operation, and shutdown through high-precision electrical parameter collection, multi-dimensional fault criterion analysis, and rapid protection action output. Meanwhile, it integrates real-time monitoring, data recording, and communication interaction functions, providing reliable safety guarantees and operation & maintenance support for key equipment such as large fans, water pumps, compressors, and steel rolling motors in fields including electric power, petrochemicals, metallurgy, and cement.

With comprehensive protection functions, precise measurement accuracy, flexible configuration capabilities, and strong anti-interference performance, this relay is highly adaptable to the high-load, multi-condition, and harsh environmental operating requirements of medium-and high-voltage motors. It serves as a core component for closed-loop management of "fault early warning - precise protection - data traceability" in industrial motor control systems. It performs outstandingly in different industrial scenarios:

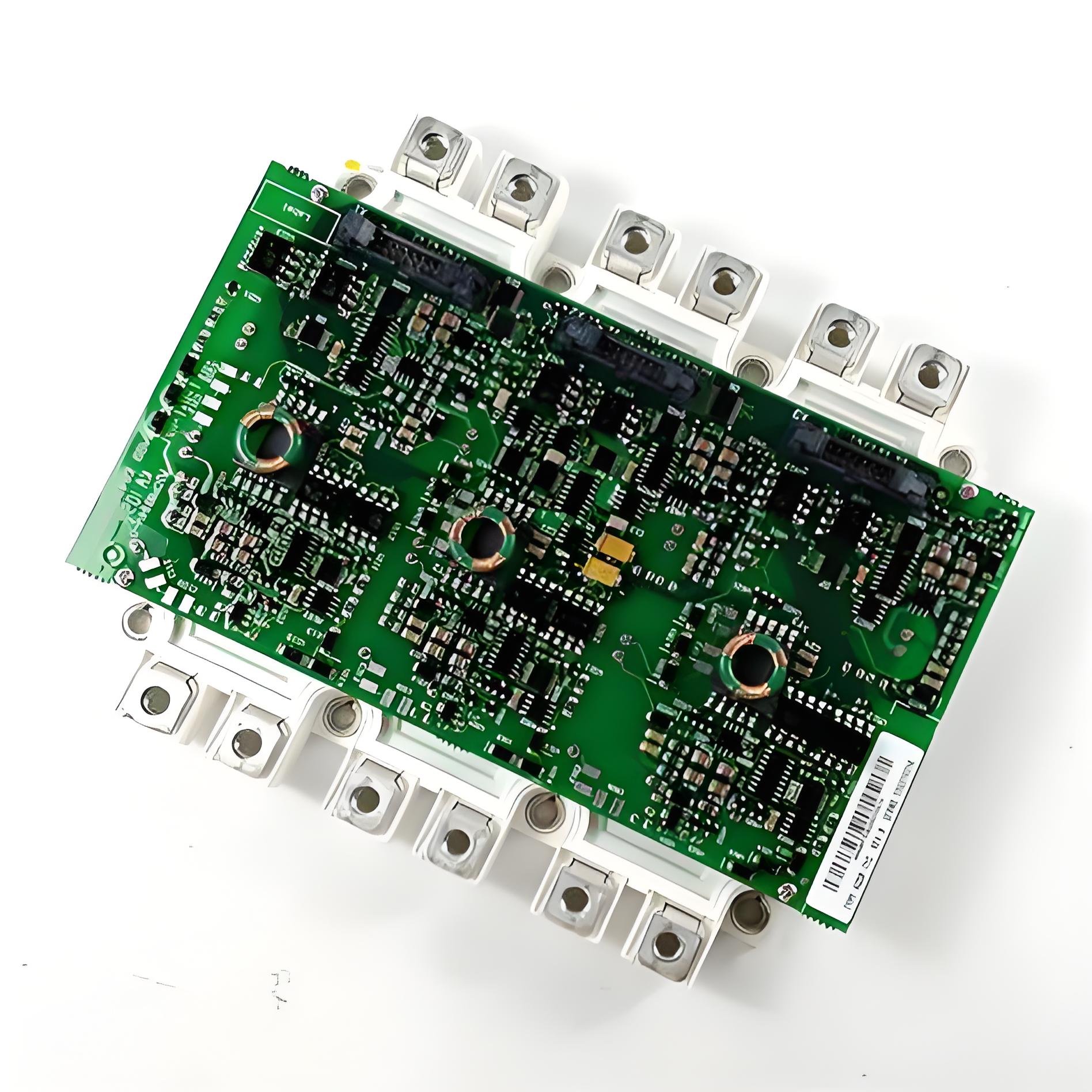

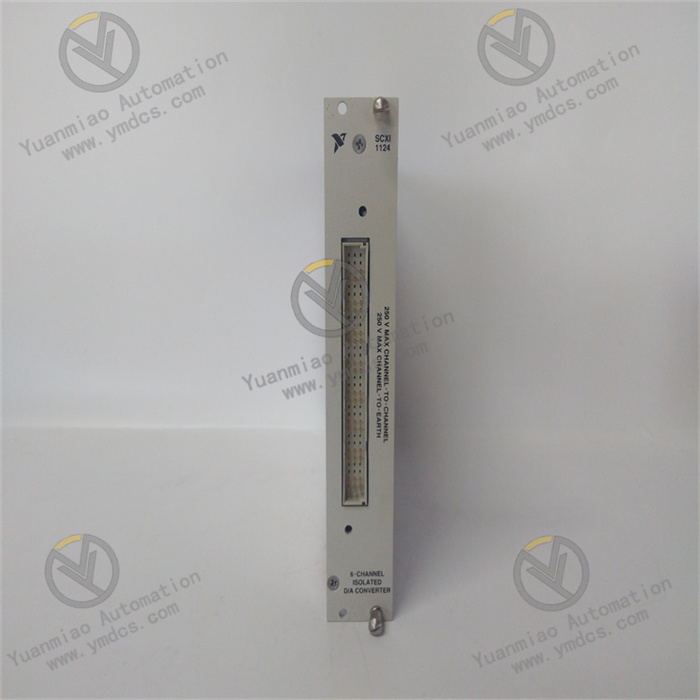

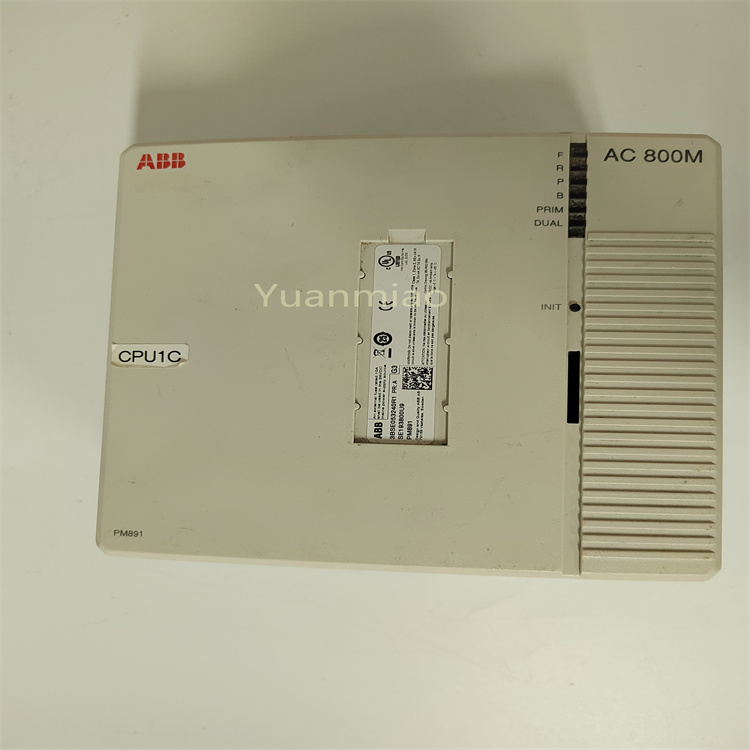

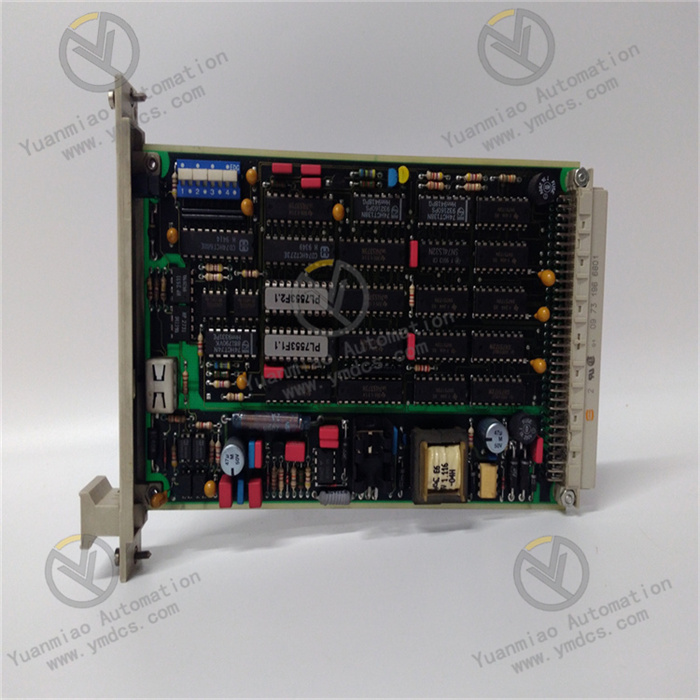

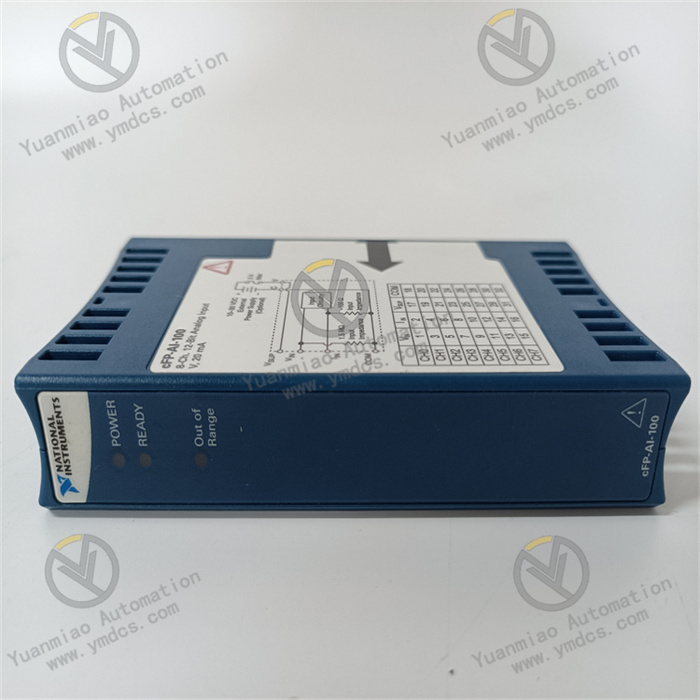

In terms of hardware architecture, the relay adopts a design of "high-precision data acquisition + multi-core processor + redundant communication". Its core consists of a 32-bit dual-core industrial-grade processor, a 16-bit high-precision A/D sampling chip, multi-channel protection output interfaces, and a multi-protocol communication module. It is equipped with 3 current input channels (compatible with programmable CT ratios from 1:1 to 1:10000), 2 voltage input channels (supporting multiple voltage levels such as 100V/220V/400V), 8 digital input channels, and 6 relay output channels (with a capacity of AC250V/5A and DC24V/10A). It has built-in dual communication interfaces (RS485 and EtherNet/IP) and supports seamless connection with mainstream monitoring systems such as GE CIMPLICITY and Siemens WinCC. Its protection functions cover all types of motor faults, including over 20 protection types such as overload protection (optional inverse time/definite time), short-circuit protection (instantaneous trip/delayed instantaneous trip), grounding protection (zero-sequence current/residual current), locked-rotor protection, phase failure protection, under-voltage/over-voltage protection, rotor bar breakage protection, and bearing temperature protection. The protection logic and action thresholds can be customized via configuration software. With an industrial-grade reinforced design, it uses wide-temperature components (-40℃~70℃), a metal shielded enclosure, and enhanced anti-electromagnetic interference circuits. Complying with international standards such as IEC 61850 and IEC 60255, it can operate stably in industrial sites with strong electromagnetic interference, high dust levels, and high humidity.

II. Technical Parameters

III. Functional Features

1. Precise Protection for Full Operating Conditions, Covering the Entire Motor Lifecycle

The relay integrates over 20 protection functions to achieve fault protection for motors during startup, operation, and shutdown phases. It adopts a "multi-criterion fusion + adaptive algorithm" to improve protection accuracy:

All protection parameters can be configured via software, with an action threshold adjustment accuracy of ±1%, making it compatible with motors of different models and specifications.

2. High-Precision Measurement & Data Recording for O&M Analysis Support

Equipped with a 16-bit high-precision A/D sampling chip and a sampling frequency of 128 points/cycle, it enables precise measurement of electrical parameters such as current, voltage, power, and frequency. The measurement accuracy is ±0.2% FS for current and voltage, and ±0.5% FS for power, meeting the requirements of energy metering levels.

It supports historical data export. Data can be exported in CSV format via USB interface or communication network, and analyzed for waveform and trend statistics using GE Multilin EnerVista software, improving the intelligence level of operation and maintenance.

3. Flexible Configuration & Intelligent Monitoring for Multi-Scenario Adaptation

It supports remote monitoring and control. Through the EtherNet/IP network, it enables remote configuration of protection parameters, real-time data collection, and remote fault diagnosis. Maintenance personnel can complete equipment debugging and fault troubleshooting without on-site operations, improving O&M efficiency.

4. Strong Anti-Interference & High Reliability for Harsh Industrial Environments

Wide-temperature components (-40℃~70℃) are used in combination with an intelligent heat dissipation design to ensure stable operation in high and low temperature environments. With an MTBF of ≥200,000 hours, it meets industrial-grade high-reliability requirements and is suitable for harsh industrial scenarios such as petrochemicals and metallurgy.

5. Multi-Protocol Compatibility & System Integration for Enhanced Expandability