Description

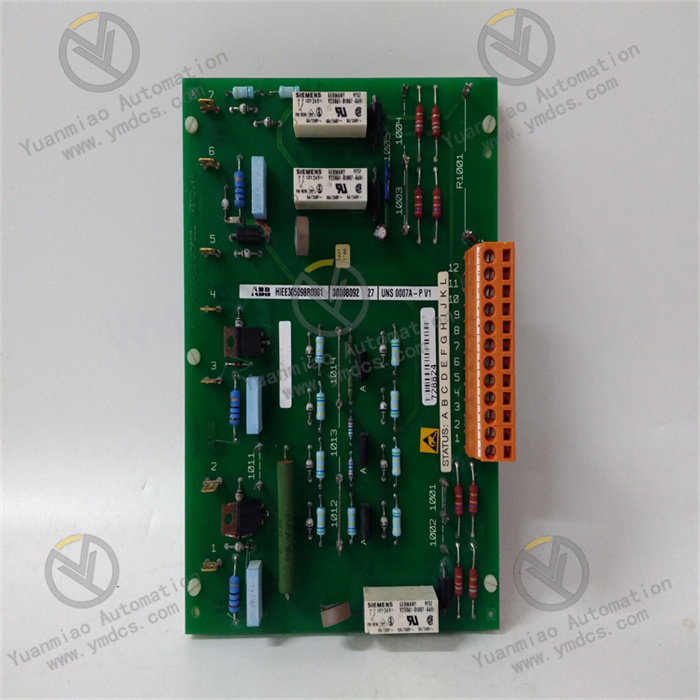

ABB PP882 3BSE069275R1

I. Functional Features

- Core Controller Module Positioning

Belongs to the processor module of ABB AC 800M series controllers, serving as the core control unit of industrial automation systems, responsible for logical operations, data processing, and system coordination.

Supports multiple industrial communication protocols such as Profibus, Ethernet/IP, Modbus, etc., enabling seamless communication with distributed I/O modules, sensors, actuators, and other devices. - High-Performance Processing Capability

Multi-core processor architecture: Enables high-speed data processing and multi-task parallel execution, supporting complex control algorithms (such as PID control, motion control, safety logic, etc.).

Real-time operating system (RTOS): Ensures precise timing and deterministic response for control tasks, meeting industrial real-time control requirements. - High Reliability and Redundancy Design

Industrial-grade durability: Adaptable to harsh environments such as high temperature, vibration, and electromagnetic interference, passing strict anti-interference tests (e.g., EMC certification).

Supports hot redundancy configuration: Can form a redundant system with another PP882 module to enhance system availability and avoid single-point failures (requires redundant power supplies and communication modules). - Flexible Expandability and Compatibility

Modular system integration: Can access ABB's S800 I/O modules, communication gateways, etc., to build distributed control systems (DCS) or programmable logic controller (PLC) systems.

Compatible with ABB engineering tools: Programmed and configured via ABB Control Builder M software, supporting IEC 61131-3 standard programming languages (such as LD, FBD, ST, etc.).

II. Technical Parameters

| Parameter | Description |

|---|---|

| Model | 3BSE069275R1 (PP882) |

| Processor | Multi-core processor (specific model undisclosed), main frequency ≥1 GHz |

| Memory | - Program memory: Approximately 16 MB (Flash) - Data memory: Approximately 8 MB (RAM) |

| Communication Interfaces | - 2× Ethernet interfaces (10/100 Mbps, supporting redundancy) - 1× Serial port (RS-232/485) |

| Real-Time Clock | Built-in battery backup to maintain time synchronization during power outages |

| Operating Voltage | DC 24 V (±10%) |

| Power Consumption | Approximately 10 W |

| Operating Temperature | -40°C ~ +70°C (industrial-grade wide temperature range) |

| Protection Level | IP20 (requires installation in control cabinets) |

| Dimensions (W×H×D) | Approximately 100 mm × 160 mm × 80 mm |

| Certifications | CE, ATEX (optional explosion-proof certification), IEC 61508 (functional safety, requires specific configuration) |

III. Application Scenarios

- Industrial Automation

- Manufacturing production lines: Such as automotive manufacturing, food packaging, electronic assembly, etc., to achieve equipment logic control, motion coordination, and process optimization.

- Machine tool and robot control: As a host controller, connecting to CNC systems or robot controllers to perform high-precision positioning and trajectory planning.

- Process Control and Energy Industry

- Chemical/petroleum/metallurgy: Used in distributed control systems (DCS) to monitor parameters such as temperature, pressure, and flow rate of reactors, distillation columns, kilns, and other equipment.

- Power and renewable energy: Implements energy management, grid connection control, and fault protection in power plants, photovoltaic inverters, and energy storage systems.

- Municipal and Infrastructure

- Sewage treatment plants: Controls the start-stop and interlocking of pumps, valves, and aeration systems to automate sewage treatment processes.

- Rail transit: Used for tunnel ventilation systems, elevator control, or platform equipment monitoring to ensure stable operation of public facilities.

IV. Operation and Maintenance Recommendations

- Installation Notes

- Physical installation: Vertically installed on a standard DIN rail, ensuring sufficient heat dissipation spacing between modules (≥20 mm).

- Electrical connections:

- Power cables must use shielded cables and be routed separately from communication cables to reduce electromagnetic interference.

- In redundant systems, correctly connect redundant communication cables and synchronization signal lines.

- Environmental requirements: Install in dust-proof and moisture-proof control cabinets to avoid direct exposure to corrosive gases or dusty environments.

- Parameter Configuration and Programming

- Initialization setup: Download programs to the module via Control Builder M software, configuring parameters such as IP address, communication protocols, and I/O mapping.

- Redundancy configuration (if needed): Enable hot redundancy to ensure real-time data synchronization between primary and backup modules, with no control interruption during switching.

- Maintenance and Fault Troubleshooting

- Status monitoring:

- Judge operating status via module indicator lights:

- PWR (Power): Constantly on indicates normal power supply.

- RUN (Operation): Flashing indicates program is running.

- ERR (Error): Constantly on indicates hardware or software faults, requiring diagnosis log review.