Description

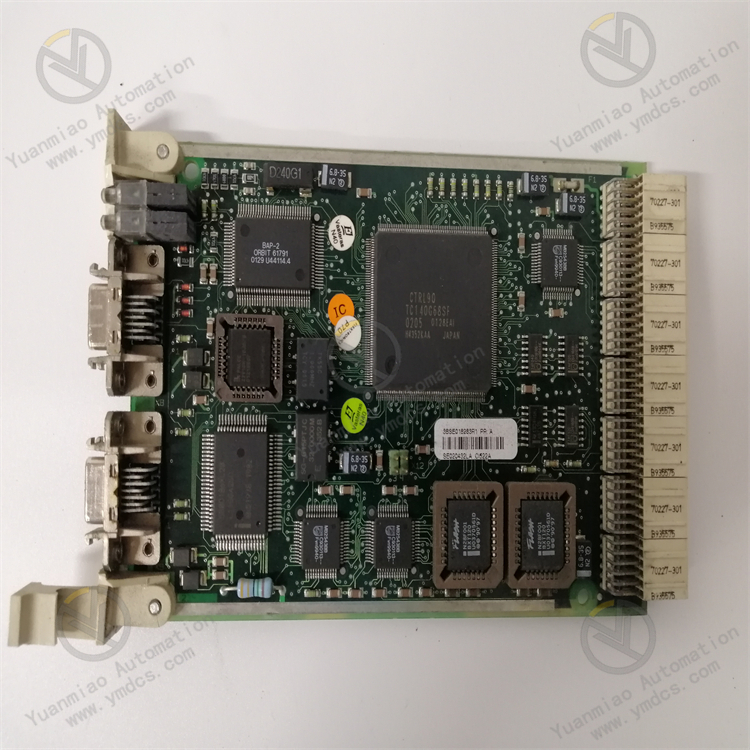

GE IC697CPX928

The GE IC697CPX928 is a Central Processing Unit (CPU) module, serving as a core control component of the Series 90-70 Programmable Logic Controller (PLC) system. It is mainly positioned as the "computing and control core" for medium-to-large industrial control systems. Equipped with a high-performance processor, large-capacity storage, and rich expansion interfaces, this module undertakes core tasks such as system program operation, logical calculation, data processing, equipment control, and communication coordination. It provides accurate and reliable control support for complex industrial processes in fields such as electric power, chemical engineering, metallurgy, and intelligent manufacturing.

Leveraging GE's profound technical accumulation in the industrial automation field, the IC697CPX928 module boasts core advantages including high computing speed, large storage capacity, strong expansion capability, high reliability, and wide compatibility. As a high-end CPU model in the Series 90-70 series, it is perfectly compatible with the series' backplane bus, I/O modules, communication modules, and special function modules, enabling flexible construction of distributed control systems ranging from small-to-medium to large scales. The module adopts an industrial-grade reinforced design, featuring excellent resistance to electromagnetic interference, voltage fluctuation, and wide-temperature adaptability. It can operate stably for a long time in harsh industrial sites with high temperature, high humidity, and strong interference. In addition, the module supports functions such as online programming, fault self-diagnosis, and redundant configuration, which greatly improve the maintainability and reliability of the system. It is a core component for medium-to-large industrial control projects to achieve precise control and efficient management.

The module is equipped with a 32-bit RISC high-performance processor with a main frequency of 200MHz. Combined with a hardware floating-point arithmetic unit and 2MB high-speed cache, it achieves extreme computing efficiency. The Boolean operation speed is as low as 0.1μs/instruction, enabling rapid processing of large-scale discrete control logic; the 64-bit floating-point operation speed is 1.2μs/instruction, which can accurately complete numerical calculations for complex processes (such as PID regulation, flow accumulation, temperature compensation, etc.). For example, in a large chemical reactor control system, the CPU needs to simultaneously handle 20 PID regulation loops, 1000+ I/O signal acquisitions, and 10 communication data interactions. The IC697CPX928 can ensure that the regulation cycle of each control loop is ≤ 10ms and the temperature control accuracy reaches ±0.1℃ through a multi-task scheduling mechanism, which is far superior to the control performance of ordinary CPU modules.

It is equipped with 16MB non-volatile Flash program memory (expandable to 32MB), which can store massive control programs, process parameters, and fault records to meet the program storage needs of medium-to-large systems; the 8MB RAM data memory is equipped with lithium battery backup (backup time ≥ 1000 hours) to ensure no loss of key data after power failure. It supports multi-rack expansion function, which can be expanded to 8 racks through the backplane bus, supporting a maximum of 8192 I/O points and enabling access to various I/O modules such as digital, analog, and pulse modules. In addition, it has 1 built-in PCI expansion slot, which can flexibly connect high-speed Ethernet modules, PROFINET modules, and special function modules (such as motion control modules and process control modules) to adapt to the personalized control needs of different industries and greatly improve system expandability.

It natively supports mainstream industrial communication protocols such as GE SRTP, Modbus RTU/ASCII, and EtherNet/IP, and can be compatible with protocols such as Profinet, DeviceNet, and Modbus TCP through expansion modules, realizing seamless connection with HMIs, DCSs, SCADA systems, and third-party intelligent devices. For example, in an intelligent manufacturing factory, the CPU connects local I/O modules through the EtherNet/IP protocol to achieve equipment control, communicates with the upper-level SCADA system through the Modbus TCP protocol to upload production data, connects to the robot system through the Profinet module to achieve collaborative operations, and accesses intelligent meters through the Modbus RTU protocol to collect energy consumption data, thereby building a comprehensive industrial communication network. The 4Mbps high-speed backplane bus ensures that the data transmission delay between the CPU and expansion modules is ≤ 5μs, guaranteeing the real-time performance of the multi-rack expansion system.

It supports 1+1 hot redundancy configuration. The main and standby CPU modules synchronize programs, data, I/O status, and control parameters in real time through a dedicated synchronization cable, with a synchronization delay ≤ 10μs. When the main CPU fails (such as power failure, operation abnormality, bus failure, etc.), the standby CPU can automatically switch to the working state within 50ms. During the switching process, the I/O output state remains unchanged and the control loop is undisturbed, ensuring continuous production process. For example, in the boiler control system of a thermal power plant, the application of redundant CPUs can avoid boiler shutdown accidents caused by a single CPU failure, improve system availability to over 99.99%, and significantly reduce economic losses caused by faults. The redundant system supports online maintenance, allowing maintenance or firmware upgrade of the main unit while the standby unit is running, further improving system maintainability.

It has a built-in comprehensive fault diagnosis system that can real-time monitor the CPU's own status (such as power supply, memory, arithmetic unit), backplane bus status, expansion module status, and I/O channel status. When a fault is detected, it immediately issues an intuitive alarm through LED indicators (power light, operation light, fault light), records the fault code, fault location, and fault time in the internal register, and uploads the information to the HMI or O&M platform through the communication interface. For example, when an analog input module fails, the CPU will accurately report "communication fault of the analog module in slot 3 of the rack", allowing O&M personnel to directly locate and replace the faulty module, reducing the fault troubleshooting time from hours to minutes. It supports online programming and program download functions, enabling program or parameter modification without shutdown, which greatly reduces the impact of O&M on production.

It adopts an industrial-grade reinforced circuit design and housing packaging, featuring excellent anti-interference and environmental adaptability. It complies with the IEC 61000-4 anti-interference standard, with ESD contact discharge of ±8kV and air discharge of ±15kV, which can resist electromagnetic radiation interference in industrial sites; its surge immunity is ±2kV, which can withstand the impact of grid voltage fluctuations. With an operating temperature range of 0℃~60℃ and a relative humidity of 5%~95% (non-condensing), it can operate stably in harsh environments such as metallurgical workshops, chemical plant areas, and outdoor control cabinets. The module has a built-in efficient heat dissipation structure, which, combined with the rack ventilation design, ensures that the temperature does not exceed 50℃ during full-load operation, extending the module's service life and reducing equipment failure rates.

Installation Specifications: Must be installed in the CPU-specific slot on the far left side of the Series 90-70 PLC standard rack; ensure the rack is well-grounded (ground resistance ≤ 4Ω); the module snaps must be fully engaged to avoid poor contact due to vibration; the distance between modules in the rack must be ≥ 15mm; the control cabinet must be equipped with a ventilation fan (air speed ≥ 1m/s) to ensure good heat dissipation; do not stack debris above the module.

Power Supply Guarantee: Ensure the backplane bus power supply outputs stably, with a voltage range of 4.75V~5.25V and a fluctuation range ≤ ±0.1V; if the on-site power grid is unstable, configure an UPS (Uninterruptible Power Supply) with a capacity ≥ 2kVA for the PLC system to ensure the CPU can complete data backup (backup time ≥ 30 seconds) in case of power failure; regularly check the lithium battery status (via programming software) and replace it in a timely manner when the battery voltage is below 3.0V to avoid data loss.

Program Management: Format the Flash memory before downloading the program for the first time to ensure the program storage area is clean; perform the "program solidification" operation after program download to prevent program loss after power failure; it is recommended to regularly back up control programs and process parameters (at least once a week), and mark the version and backup time on the backup files for easy fault recovery; enable the "online comparison" function when modifying programs to avoid incorrect modification of key logic.

Redundancy Configuration Requirements: When configuring a hot redundancy system, the main and standby CPUs must have the same model and firmware version; use GE original cables for the dedicated synchronization cable, with a length ≤ 5m to avoid signal attenuation; conduct "manual switching" and "fault switching" tests during the debugging of the redundancy system to ensure the switching time is ≤ 50ms and the control loop is undisturbed after switching; perform redundancy switching tests regularly (once a month) to verify the effectiveness of the redundancy function.

Anti-Interference Measures: The distance between the CPU module and high-voltage equipment (such as frequency converters, motors) must be ≥ 1.5m to avoid electromagnetic interference; use shielded twisted-pair cables for communication cables, with the shield layer grounded at one end; separate high-voltage cables (≥ 220V) and low-voltage cables (≤ 24V) when wiring in the control cabinet, with a distance ≥ 30cm between them, and adopt vertical crossing at intersections; it is recommended to install a surge protector at the power input end to resist lightning strikes or grid shocks.

Maintenance Taboos: Do not plug in or unplug the CPU module when the PLC system is running; the total power supply of the rack must be turned off before plugging or unplugging, otherwise the module or backplane bus may be damaged; do not touch the golden fingers on the module backplane or interface pins with metal tools to prevent short circuits; ensure stable power supply during firmware upgrade, and do not cut off the power or interrupt communication during the upgrade process, otherwise the CPU firmware may be damaged; do not modify the default system parameters inside the CPU (such as bus rate, interrupt priority); consult GE technical support if modification is necessary.

- Fault Handling: When an operation fault occurs, first check the status of the module's LED indicators (e.g., a steady-on fault light indicates an internal CPU fault, while a flashing fault light indicates a bus fault), then read the fault code via programming software; if it is a program fault (such as an infinite loop), rewrite the program through the "forced download" method; if it is a hardware fault (such as a memory fault or processor fault), replace the CPU module with the same model, and import the backup program and parameters after replacement.

![]()