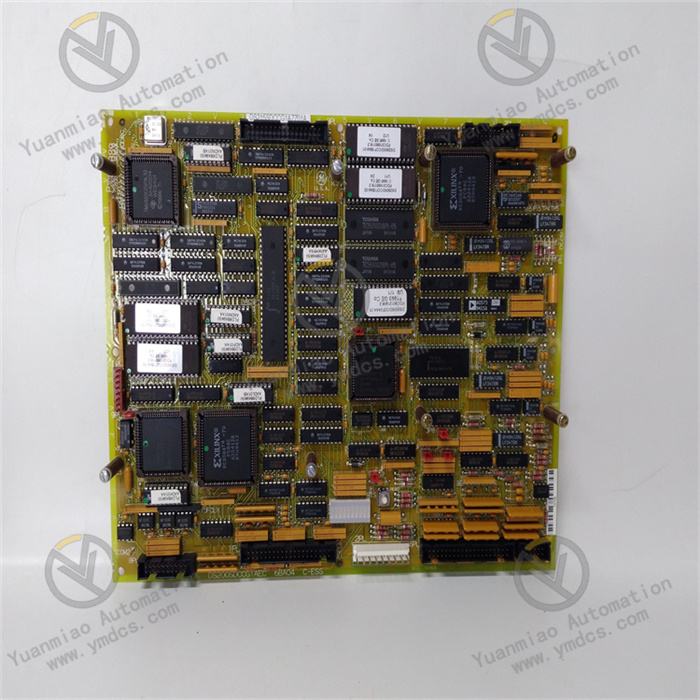

Description

GE IS200TVBAH2ACC

GE IS200TVBAH2ACC is a high-performance steam turbine valve control module developed for the Mark VIe series steam turbine control system, and it belongs to the core executive control unit family of the Mark VIe system. As a key core component of the steam turbine valve control loop, this module mainly realizes the precise drive and closed-loop control of key valves of the steam turbine, such as high-pressure main stop valves, intermediate-pressure main stop valves, high-pressure control valves, and intermediate-pressure control valves. By receiving control commands issued by the system controller and combining with valve position feedback signals, it outputs stable drive signals to servo valves or actuators, realizing accurate adjustment of valve opening. This further controls the steam intake volume and speed of the steam turbine, and ultimately ensures the stable operation of the unit.

Based on GE's advanced dedicated architecture for steam turbine control, this module adopts a 32-bit dual-core processor and high-precision closed-loop control chips. It features high control accuracy, fast response speed, strong anti-interference capability, comprehensive diagnostic functions, and support for redundant backup. It has passed the IEC 61508 functional safety certification (SIL 3 level), IEC 61000-6-4 electromagnetic compatibility certification, and UL 508 industrial safety certification. It can operate stably in harsh industrial environments with a wide temperature range of -40℃ to 70℃, high humidity, high dust, and strong electromagnetic interference. It is fully compatible with the distributed control topology of the Mark VIe system and meets the high reliability, high real-time performance, and high safety requirements for valve control of large steam turbines in fields such as thermal power, nuclear power, and petrochemical industry.

High-Precision Multi-Channel Valve Closed-Loop Control: The module integrates 4 independent valve control channels, and each channel can be independently configured to control different types of valves such as high-pressure main stop valves, intermediate-pressure main stop valves, and control valves. It supports two modes: servo valve drive and actuator control, which can be flexibly configured through the Control ST configuration software. Adopting an advanced PID + feedforward composite control algorithm and combining with the linearization processing technology of valve flow characteristic curves, the valve position control accuracy reaches ±0.1% FS. Under dynamic working conditions such as steam turbine start-stop and load fluctuation, the valve opening response time is ≤5ms and the overshoot is ≤2%, which can accurately follow the command signals issued by the controller and effectively suppress speed or load fluctuations. Each channel supports the acquisition of valve position feedback signals (4~20mA or LVDT linear displacement sensor signals) with a sampling frequency of 1kHz per channel, ensuring the accuracy of closed-loop control.

Strong Signal Conditioning and Anti-Interference Capability: Each control channel adopts an independent signal conditioning circuit and a triple isolation design (power supply isolation, input isolation, output isolation) with an isolation voltage of 2500V AC. This can effectively suppress common-mode interference, differential-mode interference, and electromagnetic radiation interference in industrial fields, ensuring the stability of signal transmission. The input channel has a built-in programmable gain amplifier (PGA) and low-pass filter, which can automatically adjust the gain (1~100 times adjustable) according to the amplitude of the feedback signal and filter out high-frequency noise (cut-off frequency 10Hz~1kHz adjustable). For LVDT feedback signals, the module has a built-in dedicated LVDT signal conditioning circuit that supports single-coil and dual-coil LVDT sensors, with a signal acquisition accuracy of ±0.05% FS. The output channel adopts a constant current/constant voltage dual-mode drive circuit, supporting ±10V voltage output or 4~20mA current output, with a load regulation rate of ≤±0.03%. It is equipped with short-circuit protection and overload protection functions. When the output is short-circuited, it can automatically limit the current to 20mA and recover automatically after the fault is eliminated, avoiding damage to the module and servo valve.

Full-Link Diagnosis and Fault Early Warning Function: The module has a built-in triple diagnostic mechanism at the channel level, module level, and system level. A dedicated diagnostic core in the dual-core processor monitors the control command signals, feedback signals, drive output signals, servo valve status, LVDT sensor status, module power supply status, and communication status of each channel in real time. The diagnostic content includes valve sticking detection (judged by comparing the difference and change rate between command and feedback), feedback signal open/short circuit detection, servo valve coil fault detection, LVDT sensor disconnection/short circuit detection, output overload/short circuit detection, power supply voltage abnormality detection, and communication interruption detection. The diagnostic information includes the fault channel number, fault type, fault timestamp, and key parameter curves (command value, feedback value, output value) before and after the fault. It can be displayed in real time through the Control ST software and uploaded to the controller and background monitoring system via the VersaWave communication bus. At the same time, the LED indicators on the front of the module will flash differently for different fault types, facilitating quick on-site fault location. In addition, the module supports a fault early warning function, which can issue early warning signals in advance by monitoring parameters such as valve sticking trends and feedback signal fluctuation amplitudes, providing data support for preventive maintenance.

Redundant Backup and Hot-Swap Support: The module adopts GE's patented redundant control architecture and supports 1+1 module-level redundant configuration. The main module and redundant module synchronize control commands, feedback data, configuration parameters, and operating status in real time through a high-speed synchronization bus, with a synchronization delay of ≤1ms. When the main module fails, the redundant module can switch to the working state without disturbance within ≤3ms, and the valve opening fluctuation during the switching process is ≤±0.5% FS, ensuring the continuity of steam turbine valve control and avoiding unit operating condition fluctuations. The module supports the hot-swap function, adopting a dedicated hot-swap mechanical structure and circuit design. When the Mark VIe system is not shut down and the unit is operating normally, the module can be directly plugged in and replaced. After replacement, the module automatically synchronizes configuration parameters and control algorithms from the controller without re-calibration and re-configuration, greatly shortening maintenance downtime and improving unit availability.

Flexible Configuration and System Integration Capability: The module supports full-parameter visual configuration through the GE Control ST configuration software. It can configure parameters such as channel control type (main stop valve/control valve), control algorithm parameters (PID proportional coefficient, integral time, derivative time), valve flow characteristic curve (linear, quick-opening, slow-opening), feedback signal type (4~20mA/LVDT), alarm threshold, and fault handling strategy. After configuration, it can be downloaded to the module online without restarting the device. Adopting the standard VersaWave communication interface of the Mark VIe system, it supports high-speed communication with the system controller (such as IC695CRU320) via optical fiber or copper cable, with a communication rate of 1Gbps and a data transmission delay of ≤1ms, meeting the strict real-time requirements for steam turbine control. The module supports connection with the GE Predix industrial cloud platform, and can upload data such as valve control parameters, operating status, and diagnostic information to the cloud, realizing remote monitoring, fault diagnosis, and performance optimization.

High Reliability and Wide Environmental Adaptability Design: It adopts a fanless natural heat dissipation design. The module shell is made of high-strength aluminum alloy with dense heat dissipation fins. Combined with the optimized internal circuit layout and thermal pads, it ensures the module operates stably within a wide temperature range of -40℃ to 70℃. The core components are all industrial-grade long-life products, such as high-precision AD/DA conversion chips (service life ≥100,000 hours), imported military-grade capacitors (service life ≥80,000 hours @85℃), and gold-plated connectors (plug-in times ≥1,000 times). Combined with strict environmental stress screening (ESS) tests (including high-temperature aging, low-temperature impact, vibration test, electromagnetic compatibility test, etc.), the mean time between failures (MTBF) of the module is ≥250,000 hours, meeting the long-term continuous operation requirements of large steam turbines.

![]()