Description

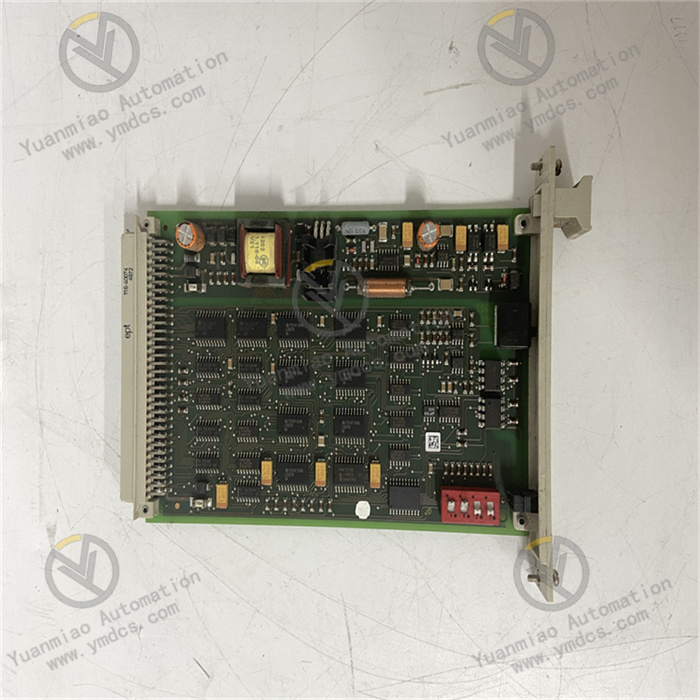

ABB CI869K01 3BSE049110R1

Functional Features:

Fieldbus Connection: As a communication interface module for AC 800M, it connects to the AF100 fieldbus via twisted pair (TWP) to enable AF100 bus-based communication between the AC 800M controller and other devices.

Fieldbus Connection: As a communication interface module for AC 800M, it connects to the AF100 fieldbus via twisted pair (TWP) to enable AF100 bus-based communication between the AC 800M controller and other devices.

Multi-Device Communication Support: Enables the connected AC 800M controller to act as an AF100 station, allowing it to connect with other AC 800M, AC 160, or connection servers, and receive data or device information from other AF100 stations. This facilitates information interaction and collaborative operation among multiple devices in the system.

High-Integrity System Application: Suitable for AC 800M high-integrity systems, meeting application scenarios with high requirements for system reliability and stability, such as critical control processes in industrial automation.

Redundancy Configuration Capability: Can be configured with redundant cables and communication interfaces. Using two CI869 modules supports Advant Fieldbus 100 redundancy. If one communication path or module fails, the other automatically takes over, ensuring continuous communication and system stability.

Integrated Modem: Incorporates a twisted pair modem to facilitate effective signal transmission, modulation, and demodulation over twisted pair cables, ensuring communication quality and efficiency.

Internal Structure: The CI869 expansion unit includes CEX-Bus logic, a communication unit, and a DC/DC converter. The DC/DC converter provides the required voltage from a +24V power supply via the CEX-Bus, ensuring stable power for the normal operation of internal units.

Application Scenarios: Mainly applied in industrial automation control scenarios related to the AC 800M controller in ABB Advant 800xA systems. For example, in production process control for industries such as chemical, power, and metallurgy, it enables reliable communication between controllers and field devices, other controllers, or servers to monitor, control, and optimize production processes.

Working Principle:

Power Supply and Conversion: The DC/DC converter in the CI869 expansion unit draws power from a +24V supply via the CEX-Bus and converts it into the voltages required by internal units, providing stable power support for the module’s operation.

Power Supply and Conversion: The DC/DC converter in the CI869 expansion unit draws power from a +24V supply via the CEX-Bus and converts it into the voltages required by internal units, providing stable power support for the module’s operation.

Fieldbus Communication: Connected to the AF100 fieldbus via twisted pair (TWP), it uses a built-in twisted pair modem to modulate data signals from the AC 800M controller for transmission over the AF100 bus, and demodulates signals from other devices into digital signals understandable by the AC 800M controller. This enables data interaction between the AC 800M controller and other AF100 stations (e.g., other AC 800M, AC 160, or connection servers).

Acting as an AF100 Station: Enables the connected AC 800M controller to function as an AF100 station, communicating with other devices on the bus according to AF100 bus protocol specifications to receive and transmit data, thereby participating in information interaction and control processes within the entire industrial automation system.

Redundancy Function Implementation: Configurable with redundant cables and communication interfaces, using two CI869 modules supports Advant Fieldbus 100 redundancy. During normal operation, both CI869 modules monitor and transmit data simultaneously. If one fails, the other automatically assumes full communication tasks, ensuring uninterrupted communication and enhancing system reliability.

How to Configure Redundancy for ABB CI869K01 3BSE049110R1?

Configuring the redundancy function of ABB CI869K01 3BSE049110R1 requires corresponding hardware and software settings. The main steps are as follows:

Configuring the redundancy function of ABB CI869K01 3BSE049110R1 requires corresponding hardware and software settings. The main steps are as follows:

1. Hardware Configuration

Dual Module Installation

Install two CI869K01 modules in the CEX bus expansion slots of the AC 800M controller, each connected to a separate physical channel (e.g., redundant AF100 buses).

Install two CI869K01 modules in the CEX bus expansion slots of the AC 800M controller, each connected to a separate physical channel (e.g., redundant AF100 buses).

Redundant Cable Connection

- Connect the two CI869 modules to redundant AF100 bus cables (typically labeled “Redundant Bus A” and “Redundant Bus B”).

- Ensure proper configuration of bus termination resistors (usually enabled on devices at both ends of the bus).

Power Redundancy

Ensure both CI869 modules are powered by a redundant power supply to avoid single-point failures.

Ensure both CI869 modules are powered by a redundant power supply to avoid single-point failures.

2. Software Configuration (Control Builder M)

1. Create Redundant CI869 Devices

- Add two CI869 modules as independent devices in the Control Builder M project.

- Assign unique hardware addresses (e.g., Slot numbers) to each module.

2. Configure Redundancy Parameters

- Open the property settings of the CI869 module and, in the “Redundancy” tab:

- Enable redundancy mode (typically select “Redundant Pair” or a similar option).

- Specify primary and secondary relationships (e.g., “Primary” and “Secondary”).

- Configure switching logic (e.g., automatic or manual switching).

3. Set Bus Parameters

- Configure AF100 bus parameters for each CI869 module to ensure:

- Consistent baud rate and communication protocol.

- Unique device addresses compliant with AF100 bus specifications.

4. Redundancy Diagnostics and Monitoring

- Add system variables to monitor CI869 module status (e.g., communication quality, redundancy status).

- Configure alarm functions to trigger alerts when redundancy switching occurs or module faults are detected.

3. Example Configuration Code Snippet

The following is a partial code example for configuring CI869 redundancy in Control Builder M (using ST language):

iecst

// Define CI869 redundancy status variables VAR CI869_RedundancyStatus : BOOL; // Redundancy status (TRUE = normal, FALSE = fault) CI869_PrimaryOK : BOOL; // Primary module status CI869_SecondaryOK : BOOL; // Secondary module status END_VAR // Monitor CI869 module status CI869_PrimaryOK := CI869_1^.Status.Word.Bits.OK; // Primary module status bit CI869_SecondaryOK := CI869_2^.Status.Word.Bits.OK; // Secondary module status bit // Determine redundancy status CI869_RedundancyStatus := CI869_PrimaryOK OR CI869_SecondaryOK; // Redundancy switching logic (example) IF NOT CI869_PrimaryOK AND CI869_SecondaryOK THEN // Trigger switch from primary to secondary module CI869_2^.Control.RedundancySwitch := TRUE; END_IF;

4. Verification and Testing

Online Monitoring

Check the status of both CI869 modules via Control Builder M’s online monitoring function.

Check the status of both CI869 modules via Control Builder M’s online monitoring function.

Redundancy Switching Test

- Simulate a primary module failure (e.g., disconnect power or communication cables) in a safe environment.

- Observe whether the system automatically switches to the secondary module and whether communication remains uninterrupted.

Recovery Test

- After fixing the fault, verify whether the system automatically restores redundancy or switches back to the primary module according to predefined logic.