Description

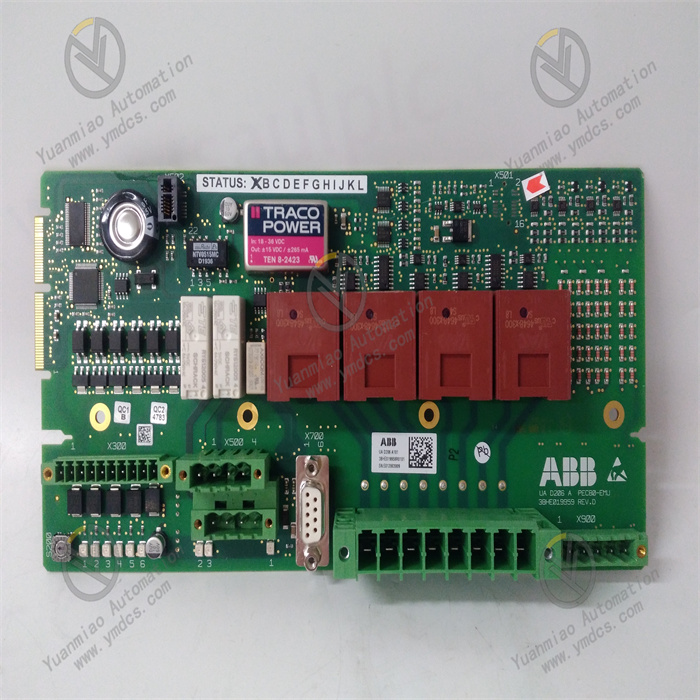

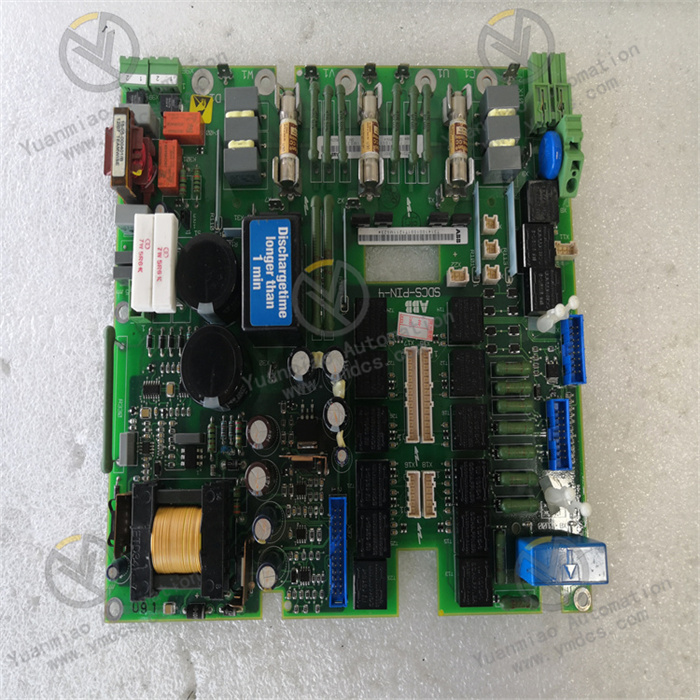

ABB PCD232A 3BHE022293R0101

Functional Features

Powerful Processing Capability: Equipped with an Intel® Atom® x5-E3940 quad-core central processing unit (CPU), it enables high-speed data processing and multitasking, capable of running multiple control tasks simultaneously. It supports floating-point arithmetic, mathematical functions, logical operations, etc., meeting the requirements of complex control algorithms.

Abundant Storage and Expansion: Features a built-in 204-pin DDR3L-1867 SO-DIMM slot memory module with a maximum capacity of 8GB, providing ample RAM. Additionally, it includes a PCI Express Mini Card slot supporting mSATA storage interface and an M.2 Key B slot supporting SATA storage interface or PCIe x2 interface for easy storage expansion.

Diverse Interface Design:

- USB Interfaces: 2 high-speed USB 3.1 Gen1 ports and 2 USB 2.0 ports for connecting various external devices.

- Network Ports: 3 GbE LAN ports for high-speed network communication.

- Serial Ports: 1 RS-232 port and 1 RS-232/422/485 port to meet different serial communication needs.

- Storage Interface: 1 SATA-600 port for connecting storage devices.

- Digital I/O: 8-channel DIO for digital input/output control.

- Audio Interface: 1 high-fidelity HD audio port for audio-related functions.

Flexible Communication Functions: Supports multiple communication protocols for seamless communication with other devices. It enables reliable data interaction between ABB AC800PEC controllers and other devices on the communication network, suitable for communication scenarios in various industrial automation systems.

Wide Temperature Operation: Capable of operating in a wide temperature range from -40°C to +70°C, adapting to harsh industrial environments and ensuring stable performance under different temperature conditions.

Technical Parameters

Power Supply: +12V DC input with AT auto-power-on function.

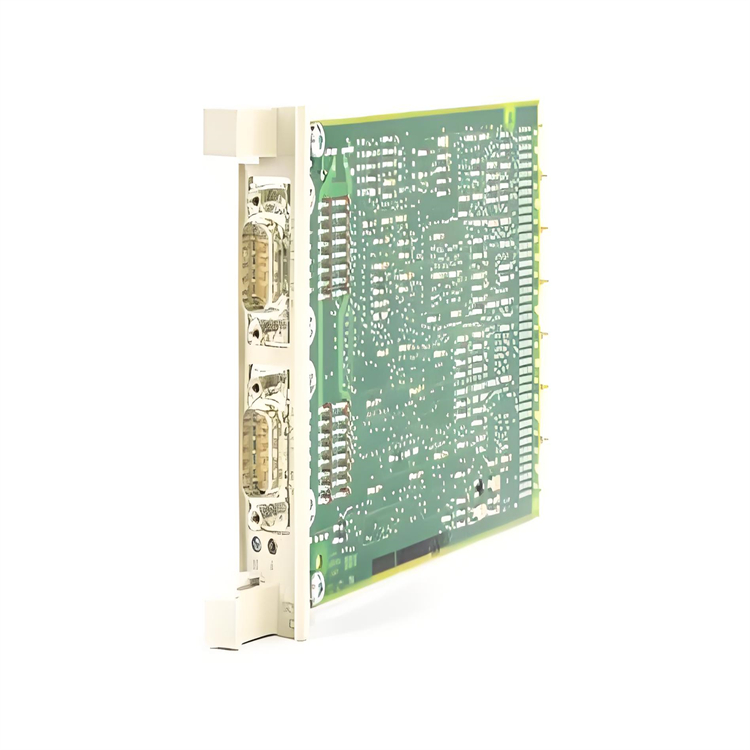

Dimensions and Weight:

Dimensions and Weight:

- Depth/Length: 142 mm

- Height: 373 mm

- Width: 73.5 mm

- Net Weight: Approximately 1.53 kg

Storage: Built-in DDR3L memory (up to 8GB), expandable via relevant slots.

Interfaces: - USB: 2 USB 3.1 Gen1 (high-speed) and 2 USB 2.0 ports

- Network: 3 GbE LAN ports

- Serial: 1 RS-232 port and 1 RS-232/422/485 port

- Storage: 1 SATA-600 port

- Digital I/O: 8-channel DIO

- Audio: 1 high-fidelity HD audio port

Working Principle

1. Data Acquisition and Input Processing

Sensor Signal Access:

- Acquires electrical parameters (e.g., terminal voltage, stator current, rotor current) of generators through analog input (AI) interfaces (e.g., 4-20mA, 0-10V), as well as non-electrical parameters (e.g., temperature, rotational speed).

- Receives switch status signals (e.g., circuit breaker on/off status) through digital input (DI) interfaces.

Signal Conditioning and Analog-to-Digital Conversion (ADC):

- Analog signals are conditioned (filtered, amplified, etc.) and converted to digital signals by ADC for processing by the module’s central processing unit (CPU).

2. Control Algorithms and Logical Operations

Core Control Algorithms:

- Voltage Regulation: Uses PID (Proportional-Integral-Derivative) control algorithms or advanced strategies (e.g., adaptive control, predictive control) to calculate required excitation current adjustments based on the deviation between the set voltage reference and actual measured values.

- Reactive Power Control: Balances reactive power distribution among generators in multi-machine parallel scenarios by adjusting excitation current to maintain grid stability.

- Protection Logic: Built-in protection algorithms for overvoltage, undervoltage, overcurrent, overheating, etc. Rapidly triggers protective actions (e.g., blocking excitation output, sending alarm signals) when anomalies are detected.

Multitask Processing:

- The module can simultaneously run logic control, parameter calculation, communication tasks, etc., with task scheduling and resource allocation managed by a real-time operating system (RTOS).

3. Output Control and Execution

Digital Output (DO) and Analog Output (AO):

- Sends switch signals (e.g., thyristor trigger pulses) through DO interfaces to control the on/off of excitation power units.

- Outputs analog signals (e.g., 4-20mA) through AO interfaces to adjust the set value of the excitation regulator.

Interface Expansion:

- If built-in I/O is insufficient, expandable modules can be connected via fieldbuses (e.g., PROFIBUS, PROFINET) to increase input/output channels.

4. Communication and System Integration

Industrial Communication Protocols:

- Supports Modbus TCP, Ethernet/IP, PROFINET, etc., for data exchange with host computers or other devices (e.g., PLCs, HMIs), enabling:

- Remote parameter setting (e.g., voltage setpoints, PID parameters)

- Real-time status monitoring (e.g., module operating temperature, I/O status)

- Fault data upload and historical record query

Redundant Communication Design (Optional):

- Some models support dual network port redundancy to enhance communication reliability and avoid single-point failures.

5. Power Supply and Reliability Design

Power Management:

- Typically powered by DC (e.g., 24V DC), with internal power modules converting it to voltages required by CPU, communication chips, I/O interfaces, etc. (e.g., +5V, +3.3V). Some models support power redundancy to prevent supply interruptions.

Anti-Interference and Protection:

- Uses industrial-grade components and electromagnetic compatibility (EMC) design to adapt to harsh environments (high temperature, vibration, strong electromagnetic interference).

- Built-in self-diagnostic functions to monitor module status in real time (e.g., memory errors, communication anomalies), with alarms indicated via LEDs or software.

Typical Application Scenarios

The PCD232A is commonly used in the following scenarios:

Synchronous Generator Excitation Control:

Synchronous Generator Excitation Control:

- Maintains generator voltage stability in power plants and captive power stations, supporting grid-connected or island operation modes.

Industrial Automation Systems:

- Serves as a core controller in closed-loop control of complex industrial processes (e.g., motor speed regulation, process parameter adjustment).

Renewable Energy Fields:

- Adjusts generator excitation in wind and hydropower systems to adapt to fluctuating input power and improve power quality.

Common Faults and Solutions

Communication Faults

Symptoms: Communication interruption with other devices, data transmission errors, or address conflicts.

Causes: Poor communication cable connections, damaged/wrongly wired cables, mismatched communication protocol settings, faulty communication chips or firmware, electromagnetic interference.

Solutions:

Causes: Poor communication cable connections, damaged/wrongly wired cables, mismatched communication protocol settings, faulty communication chips or firmware, electromagnetic interference.

Solutions:

- Check and replace communication cables or interface terminals.

- Verify that communication parameters match the system and reset to default configurations if needed.

- Use diagnostic tools to test module responses and troubleshoot protocol compatibility.

- Employ shielded cables, add filters, or relocate away from interference sources.

Power Supply Faults

Symptoms: No power to the module, unlit indicator lights, or frequent restarts.

Causes: Abnormal external power input, loose/oxidized power interfaces, internal power circuit failures.

Solutions:

Causes: Abnormal external power input, loose/oxidized power interfaces, internal power circuit failures.

Solutions:

- Check if the external power supply meets specifications and measure voltage stability with a multimeter.

- Reconnect power connectors and clean interfaces to remove oxidation.

- If the external power supply is normal but the module still fails to power on, contact ABB technical support or replace the module (likely an internal power fault).

Interface Faults

Symptoms: No response to input signals or abnormal output signals.

Causes: Faulty input signal sources, overloaded/short-circuited output loads, loose/oxidized/burnt I/O terminals, damaged internal I/O channels.

Solutions:

Causes: Faulty input signal sources, overloaded/short-circuited output loads, loose/oxidized/burnt I/O terminals, damaged internal I/O channels.

Solutions:

- Test input signals and replace sensors or repair circuits.

- Check if loads meet rated parameters and manually test outputs to identify faults.

- Clean and retighten I/O terminals; replace terminal blocks if necessary.

Overheating Faults

Symptoms: Excessive module temperature or overheat protection activation.

Causes: Poor ventilation/dusty environments blocking cooling vents, increased power consumption due to aging internal components.

Solutions:

Causes: Poor ventilation/dusty environments blocking cooling vents, increased power consumption due to aging internal components.

Solutions:

- Clean the module and its installation environment to ensure unobstructed vents.

- Reduce module load or improve environmental temperature (e.g., install cooling fans).

Firmware or Configuration Faults

Symptoms: Failed initialization, abnormal functions, or parameter loss.

Causes: Interrupted firmware updates, incorrect configuration parameters, memory failures.

Solutions:

Causes: Interrupted firmware updates, incorrect configuration parameters, memory failures.

Solutions:

- Redownload firmware or restore factory settings via dedicated software per ABB’s official manual.

- Re-enter correct configurations and backup configuration files.