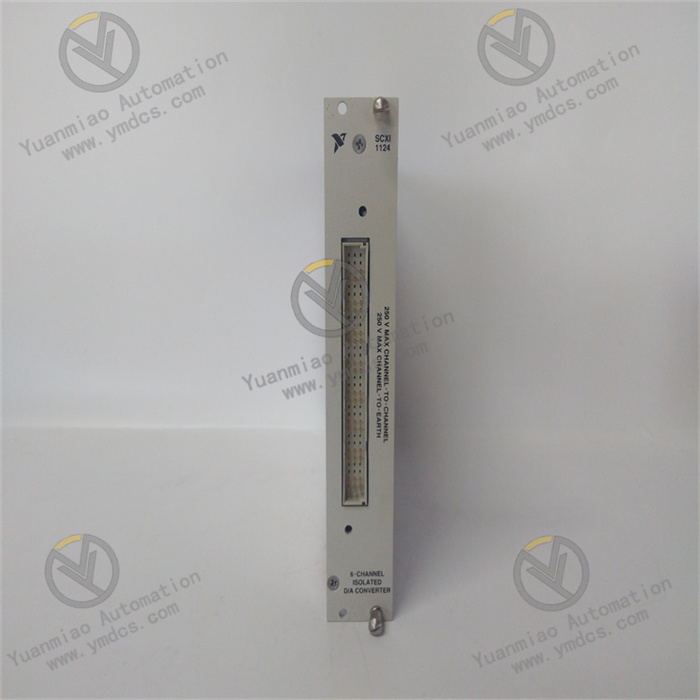

Description

SCXI - 1124 belongs to NI's SCXI (Signal Conditioning eXtension for Instrumentation) series products, and is mainly used for conditioning analog signals so that data acquisition devices can accurately collect and process these signals. Functional Features Input Types: It supports various types of analog input signals, including signals from sensors such as thermocouples, resistance thermometers, and strain gauges. For example, it can directly connect to a thermocouple to measure the temperature signal and convert it into a voltage signal suitable for processing by a data acquisition card. High-precision Measurement: It has high measurement precision and resolution, and can accurately measure tiny signal changes. It can convert input analog signals into digital signals, and maintain high precision during the conversion process to ensure the accuracy and reliability of the collected data. Signal Conditioning Function: It has various signal conditioning functions, such as amplification, filtering, and linearization. By amplifying the input signal, it can increase the amplitude of weak signals, making them easier to be detected by the data acquisition card; the filtering function can remove noise and interference in the signal to improve the signal quality; the linearization function can correct the output of non-linear sensors to make the relationship between their output and the measured quantity linear, facilitating subsequent data processing and analysis. Number of Channels: It usually has multiple input channels and can simultaneously collect signals of different positions or types. In this way, synchronous collection of multiple signals can be achieved on one module, which is convenient for comprehensive monitoring and analysis of complex systems. Isolation Characteristics: In order to prevent interference between different signals and protect the safety of equipment and personnel, SCXI - 1124 usually has an electrical isolation function. It can isolate the input signal from other parts of the data acquisition system to avoid the influence of problems such as ground potential differences and electromagnetic interference on the measurement results.

Application Scenarios Industrial Automation: In the industrial production process, it is used to monitor various physical quantities, such as temperature, pressure, and strain, to achieve the status monitoring and control of production equipment. For example, in chemical production, by collecting signals such as the temperature and pressure of the reaction kettle, the reaction process can be monitored in real time to ensure production safety and product quality. Scientific Research Experiments: In the field of scientific research, it can be used for data collection and analysis of various experiments. For example, in materials mechanics experiments, by connecting strain gauges to measure the strain changes of materials during the stress process, the mechanical properties of materials can be studied; in environmental science experiments, environmental parameters such as temperature, humidity, and air pressure can be collected to analyze the laws of environmental changes. Automotive Engineering: It is used for automotive performance testing and fault diagnosis. For example, on an automotive engine test bench, various parameters of the engine, such as temperature, pressure, and rotational speed, can be collected to analyze the working performance of the engine; during the driving process of the vehicle, by collecting vibration signals of the chassis, body and other parts, the driving comfort and reliability of the vehicle can be evaluated. Energy Field: In the power system, it is used to monitor the operating status of equipment such as generators and transformers. By collecting signals such as temperature and vibration, potential faults of the equipment can be detected in a timely manner to ensure the stable operation of the power system; in the field of new energy, such as solar and wind power generation, signals such as the voltage and current of photovoltaic cells, as well as the rotational speed and torque of wind turbines can be collected to evaluate the performance of power generation equipment and optimize control.

Some Common Faults and Solutions of NI SCXI - 1124: 1. No Signal Input in the Channel Possible Causes: Poor connection of the sensor, damaged cable, incorrect channel configuration. Solutions: Check whether the connection between the sensor and the module is firm, replace the damaged cable, confirm whether the channel configuration is correct, and reconfigure the channel parameters. 2. Inaccurate Measurement Data Possible Causes: Sensor calibration issues, external interference, improper module range setting. Solutions: Calibrate the sensor, check whether there are strong electromagnetic interference sources around, and take shielding measures. Adjust the range setting of the module to ensure that it matches the output range of the sensor. 3. Module Overheating Possible Causes: Excessive environmental temperature, poor heat dissipation, excessive module load. Solutions: Improve the installation environment of the module, ensure that there is enough space for heat dissipation around, reduce the load of the module, and avoid using too many channels simultaneously or connecting high-power sensors. 4. Communication Fault Possible Causes: Bus connection problems, un-installed or damaged driver, device address conflict. Solutions: Check whether the bus connection between the module and the computer or other devices is normal, reinstall or update the driver, ensure that the device address setting is correct, and avoid conflicts with other devices. 5. Crosstalk between Channels Possible Causes: Unreasonable cable routing, poor internal isolation of the module. Solutions: Optimize the cable routing, arrange the cables of different channels separately to avoid being close to each other. If there are suspected internal isolation problems of the module, contact NI technical support for repair or replacement. 6. Module Not Recognized Possible Causes: Hardware failure, power supply problem, software setting error. Solutions: Check whether there are signs of damage to the hardware of the module, such as bulging capacitors, etc. Ensure that the power supply of the module is normal. Check whether the device manager in the software correctly recognizes the module. If it is not recognized, try to rescan the device or update the driver.

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage