Description

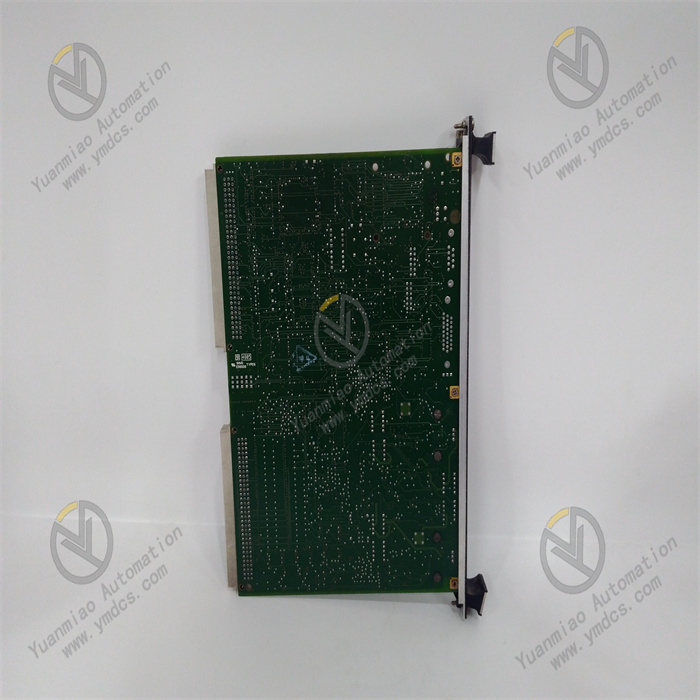

GE IS200VAICH1DAB

I. Product Overview

GE IS200VAICH1DAB is a core intelligent analog input module in the Mark VIe series digital control system for steam turbines. It is specifically designed for multi-channel, high-precision analog signal acquisition scenarios of key power equipment such as large-scale steam turbine generator units and gas turbines. It is widely used in fields with strict requirements for parameter monitoring accuracy and system reliability, including thermal power generation, combined cycle power generation, nuclear power auxiliary systems, and industrial captive power plants. As the "front-end signal acquisition hub" of the Mark VIe system, this module integrates multi-channel signal conditioning, high-precision analog-to-digital (AD) conversion, redundant communication, and full-link self-diagnosis functions. It can seamlessly connect to various analog sensors of steam turbines (for temperature, pressure, flow rate, vibration, liquid level, etc.), convert on-site physical quantities into digital signals, and transmit them to the main control module (e.g., IS200VCMIH2CAA), providing accurate and reliable raw data support for real-time monitoring, closed-loop control, and fault early warning of the unit.

II. Functional Features

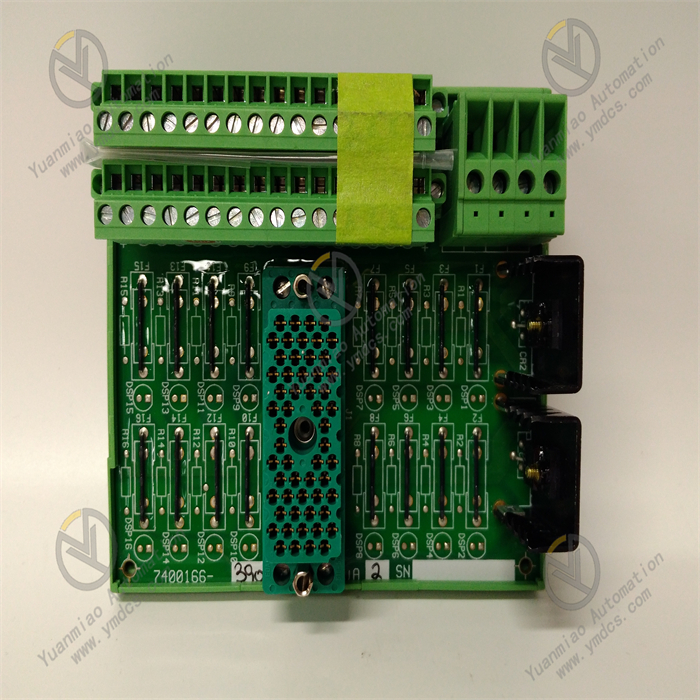

- Multi-Channel High-Precision Signal AcquisitionEquipped with 16 independent analog input channels, it supports multiple standard analog signal types including 4-20mA, 0-20mA, 0-5V, 1-5V, thermocouples (Types K, J, T, E, etc.), and RTDs (Resistance Temperature Detectors, such as PT100, Cu50, etc.). The signal type of each channel can be independently configured via configuration software to meet sensor access requirements in different scenarios. It adopts a 16-bit high-precision AD conversion chip with a conversion accuracy of ±0.05% FS, and the sampling rate can be adjusted in grades within the range of 10Hz-1000Hz. For slow-changing parameters such as temperature and liquid level, a low sampling rate can be selected to reduce system load; for fast-changing parameters such as pressure and vibration, a high sampling rate can be used to ensure signal integrity. Each channel has a built-in independent signal conditioning circuit, with overvoltage protection (±30V DC), overcurrent protection (≤50mA), and anti-aliasing filtering functions. It can effectively suppress on-site electromagnetic interference (EMC complies with IEC 61000-6-2 standard), ensuring the stability and accuracy of collected data. For example, the acquisition error of the main steam pressure of the steam turbine can be controlled within ±0.02MPa, and the acquisition error of bearing temperature is ≤±0.3℃.

- Intelligent Signal Processing and Data PreprocessingThe module has a built-in 32-bit high-performance microprocessor, supporting real-time preprocessing of collected raw signals, including functions such as signal filtering, linearization correction, range conversion, and cold-junction compensation (for thermocouple signals). For thermocouple signals, the module integrates a high-precision cold-junction compensation circuit with a compensation accuracy of ±0.1℃, effectively eliminating the impact of ambient temperature changes on temperature measurement accuracy. For non-linear sensor signals, custom non-linear correction curves can be imported via configuration software to achieve linear conversion of signals. The module has a data buffering function, which can store 1000 sets of historical collected data and support on-demand reading by the main control module. It also has functions for statistics of peak value, valley value, and average value of data, and can directly upload statistical results to the main control module, reducing the computational load of the main control module.

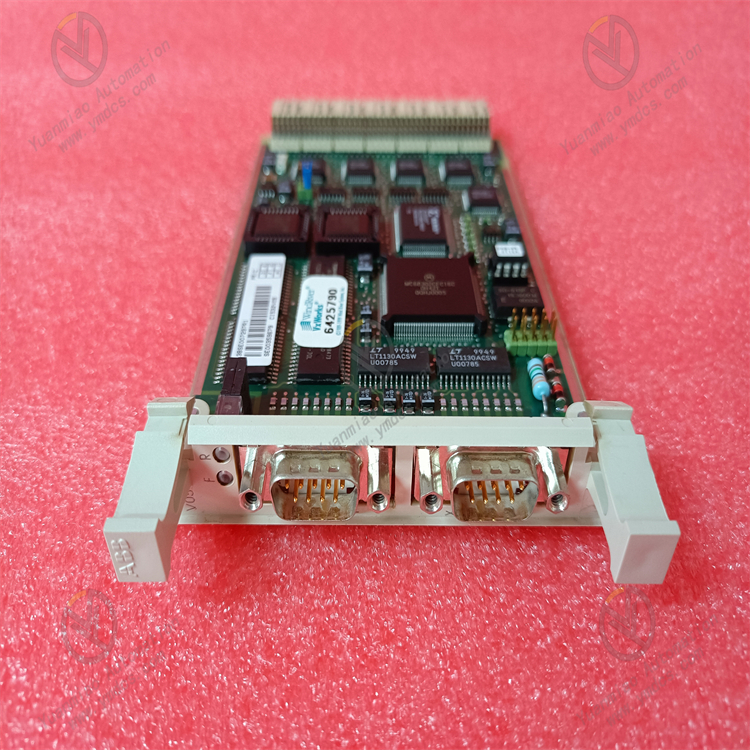

- Redundant Communication and Flexible ExpansionIt uses a dual-channel Genius redundant bus as the main communication interface, combined with one standby EtherNet/IP interface, to achieve high-speed data interaction with the main control module and upper-level systems. The communication rate of the Genius bus reaches 1Mbps, with a data transmission delay of ≤2ms. The redundant link has an automatic switching function: when the packet loss rate of the main link is ≥1% or communication is interrupted, it can seamlessly switch to the standby link within 1ms, ensuring uninterrupted data transmission. It supports the "master-slave" cascading mode: a single main control module can cascade up to 16 IS200VAICH1DAB modules, and realize inter-module data sharing via the Genius bus. It can be expanded to a maximum of 256 analog input channels, meeting the centralized acquisition needs of multiple measurement points in large-scale units. The module supports hot-swapping, allowing replacement and maintenance of the module without shutting down the system, significantly improving system availability.

- Full-Dimensional Self-Diagnosis and Fault Early WarningA three-level self-diagnosis system ("channel-level - module-level - link-level") is built, with a diagnostic coverage rate of 99.9%. Channel-level diagnosis monitors the signal status of each channel in real time: when signal over-range, short circuit, open circuit, or drift exceeding the threshold is detected, the faulty channel is immediately marked and an alarm is triggered. Module-level diagnosis performs a self-check every 10ms to monitor the working status of core components such as the AD conversion chip, microprocessor, power module, and signal conditioning circuit; if chip failure or power anomaly (input voltage lower than 19V DC or higher than 27.6V DC) is detected, a fault signal is output in a timely manner. Link-level diagnosis monitors the connection status with the main control module in real time via communication check codes, and records fault information such as communication interruption, packet loss, and data check error. Diagnostic information can be displayed locally via the LED indicators on the front panel of the module (a red light indicates a fault, and a green light indicates normal operation), and can also be uploaded to the main control module and upper-level operation and maintenance platform via the communication link. It supports storage of 1000 fault logs, each containing information such as fault time, fault type, and fault channel, facilitating quick location and troubleshooting by operation and maintenance personnel.

- Wide-Range Environmental Adaptability and Modular DesignIt has excellent environmental adaptability, with an operating temperature range of -10℃~65℃, a storage temperature range of -40℃~85℃, and a relative humidity of 5%~95% (no condensation). It can adapt to power plant environments in different regions with high altitude (≤4000m) and high humidity. Its vibration resistance complies with IEC 60068-2-6 standard (5-200Hz, 1.0g acceleration). It adopts 35mm standard DIN rail mounting, with dimensions of 160×180×85mm and a compact structure. A spacing of ≥5mm between adjacent modules can meet heat dissipation requirements, adapting to the installation layout of mainstream control cabinets. The module adopts a modular split design: the signal conditioning unit, AD conversion unit, and communication unit can be independently disassembled and replaced, reducing maintenance costs. The front panel is equipped with 16 input channel status LEDs, 2 communication status LEDs, and 1 power status LED, which can intuitively display the operating status of each channel and the module, facilitating quick on-site inspection.

- Convenient Configuration and Calibration ManagementIt supports full-parameter configuration via GE ControlST V7.0 and above configuration software. The software provides a graphical operation interface, allowing intuitive setting of parameters such as signal type, sampling rate, range, alarm threshold, and filtering coefficient for each channel. It has a built-in channel parameter copying function, enabling quick unified configuration of multiple channels. It is equipped with an online calibration function: by issuing calibration commands via the configuration software and cooperating with a standard signal source, zero-point and full-scale calibration can be performed for each channel without disassembling the module, and the calibration accuracy can be traced to national metrology standards. It supports batch import and export of parameters, facilitating unified configuration and backup of multiple modules, significantly shortening the debugging cycle and reducing debugging costs.

III. Technical Parameters

| Parameter Category | Parameter Name | Specific Parameters | Unit |

|---|---|---|---|

| Basic Parameters | Model | GE IS200VAICH1DAB | - |

| Module Type | Intelligent Analog Input Module | - | |

| Overall Dimensions (L×W×H) | 160×180×85 | mm | |

| Weight | Approximately 1.1 | kg | |

| Analog Input Parameters | Number of Input Channels | 16 channels (independent channels, signal type configurable individually) | Channel |

| Supported Signal Types | 4-20mA, 0-20mA, 0-5V, 1-5V DC; Thermocouples (Types K, J, T, E, S, R); RTDs (PT100, Cu50) | - | |

| AD Conversion Accuracy | 16-bit, ±0.05% FS | - | |

| Sampling Rate | 10Hz-1000Hz, configurable in grades (independently adjustable per channel) | Hz | |

| Input Impedance | Current signal: ≤100Ω; Voltage signal: ≥1MΩ; Thermocouple: ≥10MΩ; RTD: ≤10Ω | Ω | |

| Overvoltage Protection | ±30V DC, automatic recovery | V DC | |

| Cold-Junction Compensation Accuracy (for Thermocouple) | ±0.1℃ | ℃ | |

| Filtering Method | Digital filtering + analog anti-aliasing filtering, configurable filtering coefficient | - | |

| Power Supply Parameters | Power Supply Mode | DC power supply, supporting redundant backup | - |

| Input Voltage Range | DC 24V±15% (19.2-27.6V DC) | V DC | |

| Rated Supply Current | ≤0.6A (full load, including all channels in operation) | A | |

| Power Supply Ripple Rejection Ratio | ≥60dB (100Hz-1MHz) | dB | |

| Communication Parameters | Standard Communication Interfaces | 2-channel Genius redundant bus, 1-channel standby EtherNet/IP interface | - |

| Supported Protocols | Genius, EtherNet/IP, Modbus TCP (optional) | - | |

| Communication Rate | Genius bus: 1Mbps; EtherNet/IP: 100Mbps (full-duplex) | bps | |

| Data Transmission Delay | ≤2ms | ms | |

| Cascading Quantity | Up to 16 modules in cascade | Unit | |

| Environmental & Reliability Parameters | Operating Temperature Range | -10~65 | ℃ |

| Storage Temperature Range | -40~85 | ℃ | |

| Relative Humidity | 5%~95% (no condensation) | % | |

| Protection Class | IP20 (front panel) | - | |

| Vibration Resistance | 5-200Hz, 1.0g acceleration (IEC 60068-2-6) | - | |

| Mean Time Between Failures (MTBF) | ≥400,000 | Hour | |

| Diagnostic Parameters | Diagnostic Coverage Rate | 99.9% | - |

| Fault Log Storage | 1000 logs, including fault time, type, and channel information, non-volatile (retained when power off) | Log |

IV. Working Principle

As the core of front-end analog acquisition in the steam turbine control system, the working principle of GE IS200VAICH1DAB revolves around six core links: "signal access - signal conditioning - data conversion - intelligent processing - data transmission - diagnostic feedback". Through high-precision signal processing and redundant communication mechanisms, it achieves efficient collaboration with the main control module and provides accurate data support for unit control. The specific process is as follows:

- Power Supply and Preprocessing Link:After 24V DC power is connected through the module's power interface, it first passes through an EMC filter circuit and a surge suppression circuit to filter out high-frequency interference, transient surges, and spike pulse signals in the power grid, ensuring stable input power. Then, the DC-DC conversion unit outputs multiple sets of precise voltages such as 5V, 3.3V, and ±15V to supply power to core components including the signal conditioning unit, AD conversion unit, microprocessor, and communication unit. The output ripple is ≤5mV to ensure stable operation of each unit. At the same time, the power monitoring circuit monitors the input voltage, output voltage, and module operating current in real time. When the input voltage is lower than 19.2V or higher than 27.6V, or the operating current exceeds 0.8A, a power fault alarm is triggered immediately and uploaded to the main control module via the communication link.

- Analog Signal Access and Conditioning Link:Analog signals output by on-site sensors (such as 4-20mA current signals from pressure sensors, millivolt-level signals from thermocouples, and resistance signals from RTDs) are connected to the 16 independent input channels of the module via shielded cables. Each channel automatically matches the corresponding signal conditioning circuit according to the configuration parameters. For current/voltage signals, the conditioning circuit first adjusts the signal amplitude and performs anti-aliasing filtering, then sends the signal to the AD conversion unit after filtering out high-frequency noise. For thermocouple signals, the conditioning circuit first performs cold-junction compensation (collects ambient temperature via a built-in temperature sensor to compensate and correct the thermocouple signal), then amplifies and filters the signal. For RTD signals, the conditioning circuit generates a voltage signal through constant current source excitation, which is amplified and filtered before being sent to the AD conversion unit. During conditioning, the gain and filtering coefficient of each channel can be independently configured according to the signal type, ensuring the signal adapts to the optimal input range of the AD conversion unit.

- Analog-to-Digital Conversion and Intelligent Processing Link:The conditioned analog signal is sent to the 16-bit high-precision AD conversion chip, which converts the analog signal into a digital signal at the preset sampling rate (10Hz-1000Hz). The converted digital signal is temporarily stored in the buffer unit. The 32-bit microprocessor reads the raw digital signal from the buffer and performs intelligent preprocessing: linearization correction for non-linear signals (such as signals from some pressure sensors), secondary correction for thermocouple signals after cold-junction compensation, digital filtering for signals with large fluctuations (such as vibration signals), and calculation of statistical parameters such as peak value, valley value, and average value of the signal. The processed accurate data and statistical results are stored in the data storage unit, which can store 1000 sets of historical data for on-demand reading by the main control module.

- Data Transmission and Main Control Collaboration Link:The module establishes a communication link with the main control module via the dual-channel Genius redundant bus, and the main link is used for data transmission by default. The processed data in the data storage unit is encapsulated via the communication protocol (Genius protocol) and uploaded to the main control module according to the preset transmission cycle (synchronized with the sampling rate), while receiving configuration commands issued by the main control module (such as sampling rate adjustment, channel signal type modification, calibration commands, etc.). During communication, the link monitoring circuit verifies the CRC check code of the data frame in real time. If the main link has a packet loss rate ≥1%, communication interruption, or data check error, it immediately switches to the standby link with a switching time of ≤1ms, ensuring uninterrupted data transmission. When communication between the module and the main control module is interrupted for more than 500ms, the module automatically activates the local data storage mode to continuously store collected data, and automatically supplements and transmits historical data after communication is restored to avoid data loss.

- Full-Link Diagnosis and Feedback Link:The module performs three-level diagnosis in real time: ① Channel-level diagnosis: Each channel monitors the signal amplitude (over-range, under-range), line status (short circuit, open circuit), and signal drift (deviation from the historical average exceeds ±0.5% FS) in real time; if an anomaly is detected, the faulty channel is immediately marked and an alarm is triggered. ② Module-level diagnosis: A self-check is performed every 10ms to monitor the working status of core components such as the AD conversion chip, microprocessor, buffer unit, and power module; if a non-responsive chip, data read/write error, or power anomaly is detected, it is marked as a module hardware fault. ③ Link-level diagnosis: The communication packet loss rate and data transmission delay are counted every 100ms; if the packet loss rate is ≥1% or the delay is ≥5ms, it is marked as a communication link fault. All diagnostic information is displayed locally via the LED indicators on the front panel (a red light for the corresponding channel indicates a channel fault, and a flashing communication light indicates a communication anomaly), and is also uploaded to the main control module and upper-level platform via the communication link. Fault logs are stored in chronological order with timestamps, supporting traceability and query.