Description

Schneider Electric's 140CRA93200 is an RIO (Remote I/O) introduction adapter module in the Modicon Quantum series, mainly used to expand the I/O capabilities of the PLC, connect the remote I/O modules to the PLC, and implement a distributed I/O system. Working Principle: This module is designed to be installed on the same backplane as the control CPU module, and it transmits data bidirectionally between the PCU and the RIO drop modules located on different backplanes. To interconnect this RIO header module, a coaxial cable network is used together with at least one other RIO introduction module.

Functional Features RIO Introduction and Signal Transmission: It can connect the remote I/O modules to the PLC to expand the I/O capabilities, and it can transmit digital signals and analog signals at high speed. High Reliability and Flexible Configuration: It adopts a redundant design and supports multiple configuration methods, which can adapt to different application requirements and improve the reliability of the system. Good Electrical Characteristics: It has a dynamic range of 35dB, a 500V DC coaxial center and ground isolation voltage, ensuring the quality and safety of signal transmission. Technical Parameters Electrical Parameters: It requires a bus current of 750mA, and the typical power consumption is 3 - 3.8W. It supports 1mA CRP, and the transmission rate reaches 1544Mbit/s. Mechanical Parameters: The weight is approximately 0.55kg. There are 4 LED indicators in appearance, which are used to indicate the status of readiness, communication, Error A, and Error B, etc.; below the LED area is the ROP coaxial connector area, with Connector A and Connector B, which are used to connect to the coaxial cable network. Other Parameters: It has 31 branches and can be used in combination with the Quantum 200 series, 500 series, 800 series, or SY/MAX (any combination). It has 64 in words per drop and 64 out words per drop. The module has 2 ports per branch, with a maximum of 32 ports (16 branches), and it requires the use of AS-P892-000, AS-J892-101/102, or AS-J290-0X0 at the RIO branch.

Common Faults and Solutions Communication Faults: These may be caused by poor communication line connections, incorrect communication parameter settings, or damage to the module communication interface. It is necessary to check whether the communication line is properly connected, confirm whether the communication parameter settings are consistent with other devices, and contact the manufacturer for repair or replace the module communication interface if it is damaged. Module Faults: For situations such as abnormal LED indicators or the module not working properly. It may be due to hardware faults of the module itself, power supply problems, or external interference. First, check whether the power supply of the module is normal, check whether there are strong electromagnetic interference sources around, try to reset or reinitialize the module. If the problem still exists, contact professional maintenance personnel for inspection and repair. Abnormal Data Transmission: There may be problems such as data loss, errors, or transmission delays. The reasons may be network faults, electromagnetic interference, or incorrect module configuration. Check whether the network connection is stable, eliminate electromagnetic interference factors, check whether the data transmission configuration parameters of the module are correct, and reconfigure them if there are errors.

Application Scenarios: Manufacturing Production Lines: In production lines such as automotive manufacturing and electronic device manufacturing, it can connect various field devices such as sensors and actuators to achieve real-time monitoring and control of the production process. For example, in an automotive assembly line, through the 140CRA93200, the operation status information of devices such as body welding robots and component handling manipulators can be transmitted to the control system in real time, and at the same time, it can receive commands issued by the control system to ensure the efficient and stable operation of the production line. Power Systems: It is used in power facilities such as substations and power plants to achieve remote monitoring and control of power equipment. It can connect various intelligent devices in the power system, such as relay protection devices, smart meters, switchgear, etc., and transmit the data of these devices to the remote control center, so that the staff can master the operation status of the power system in real time, discover and handle faults in a timely manner, and ensure the safe and reliable operation of the power system. Water Treatment Systems: In water treatment facilities such as waterworks and sewage treatment plants, it can connect devices such as water quality sensors, water pumps, and valves to achieve automated control and remote monitoring of the water treatment process. Through the 140CRA93200, the staff can monitor water quality parameters and the operation status of equipment in the remote control center in real time, and remotely control the start and stop of water pumps, the opening degree of valves, etc. as needed to ensure the stable and efficient operation of the water treatment process and ensure that the water quality meets the standards. Transportation Field: For example, in rail transit systems such as subways and light rails, it can be used to connect the train signal system, station equipment monitoring system, etc. to achieve real-time monitoring and control of the train operation status and the operation of station equipment. Through the 140CRA93200, the dispatching personnel can master information such as the position, speed, and door status of the train in the control center in real time, as well as the operation status of equipment such as ventilation, lighting, and elevators in the station, so as to achieve efficient operation management and emergency handling of faults. Petrochemical Industry: In processes such as oil extraction, oil refining, and chemical production, a large number of field devices need to be monitored and controlled. The 140CRA93200 can connect various sensors (such as temperature, pressure, flow sensors) and actuators (such as control valves, pumps, etc.) to achieve precise control and remote monitoring of the production process, ensure the safety, stability, and efficiency of the production process, and facilitate the staff to discover and handle potential safety hazards and production faults in a timely manner.

Schneider Related Products

| 140XTS00200 | 140NOC77100 |

| 140XTS00500 | 140NOC77101 |

| 140CPS42400 | 140NOC78000 |

| 140CPS51100 | 140NOC78100 |

| 140ACI03000 | 140NOE25100 |

| 140AIO33000 | 140NOE31100 |

| 140ARI03000 | 140NOE35100 |

| 140ARI03010 | 140NOE51100 |

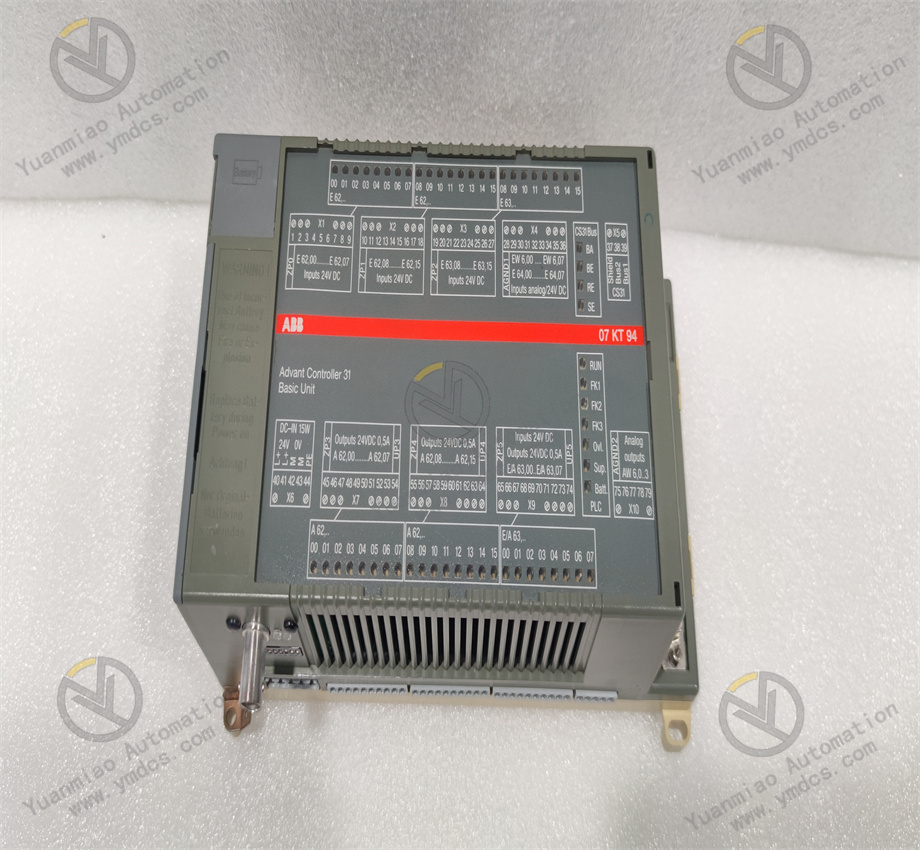

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage