Description

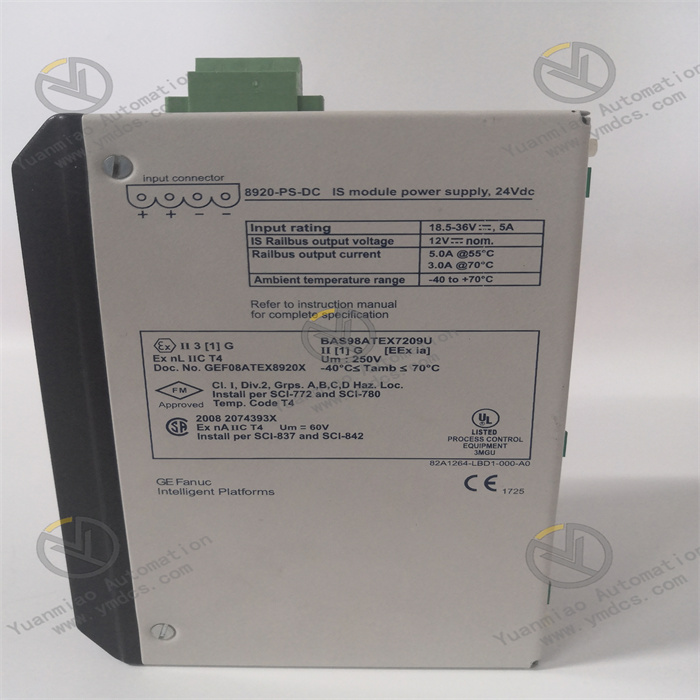

GE 8920-PS-DC

I. Overview

The GE 8920-PS-DC is a high-performance DC redundant power supply module specifically designed for industrial automation control systems. It can accurately convert the input DC voltage into a stable output power supply, providing reliable power support for control equipment such as PLCs (Programmable Logic Controllers) and DCSs (Distributed Control Systems). As an indispensable core component of GE's industrial power supply solutions, this power module plays a crucial role in power protection within complex and variable industrial environments. It ensures the continuous and stable operation of core control equipment, safeguarding the safety and efficiency of industrial production.

This product adopts a modular design, supports redundant configuration, and enables hot-swappable replacement— a feature that significantly enhances system availability. Meanwhile, it is compatible with a variety of industrial standards and can be seamlessly integrated with GE's controller series, including ControlLogix and Mark VIe, facilitating the construction of industrial automation systems. Boasting high conversion efficiency and a wide input voltage adaptation range, the GE 8920-PS-DC can meet the power supply needs of different industrial scenarios, laying a solid power foundation for the safe and reliable operation of automation systems.

II. Technical Specifications

(I) Power Supply Parameters

- Input Voltage: Supports a wide DC input range of 18-72VDC. This feature allows it to adapt to different industrial DC power supply environments without the need for additional voltage conversion equipment, simplifying the system wiring and configuration process while improving the equipment's applicability across various scenarios.

- Output Voltage: Provides a stable output of 24VDC with an error margin controlled within ±0.5V. The stable output voltage ensures that the connected control equipment is not affected by voltage fluctuations, enabling the automation system to operate accurately and reducing equipment failures and data errors caused by unstable voltage.

- Output Current: Offers a maximum output current of up to 20A, capable of powering multiple control devices simultaneously. This meets the power requirements of multi-device collaborative operations in industrial automation systems.

- Conversion Efficiency: Typically reaches 92% under full-load conditions. High conversion efficiency effectively reduces energy loss, lowers the temperature rise of the equipment during operation, enhances the overall system energy efficiency, and aligns with the industrial development trend of energy conservation and environmental protection.

(II) Physical and Environmental Parameters

- Dimensions: Features physical dimensions of 160mm×100mm×60mm. Its compact structural design allows for easy installation in control cabinets with limited space, improving the space utilization rate inside the cabinets.

- Weight: Weighs approximately 500g. The lightweight design not only facilitates transportation and installation but also reduces the labor intensity during the installation process.

- Operating Temperature: Operates within a temperature range of -25℃ to +70℃, enabling normal operation in extreme temperature environments and adapting to various harsh industrial on-site conditions.

- Storage Temperature: Can be stored within a temperature range of -40℃ to +85℃. Even when stored for extended periods without use, it ensures the product's performance remains unaffected, extending its service life.

- Protection Rating: Achieves an IP20 protection rating, making it suitable for installation inside control cabinets. It can effectively prevent dust and other debris from entering the module, protecting internal circuit components from damage.

(III) Other Key Parameters

- Redundancy Function: Supports N+1 redundant configuration. When one of the power modules fails, the redundant module can realize seamless switching, avoiding system power supply interruptions. This greatly improves the reliability of the power supply system and is suitable for industrial scenarios with extremely high requirements for continuity.

- Protection Functions: Equipped with comprehensive protection functions, including overcurrent protection, overvoltage protection, overtemperature protection, and short-circuit protection. When abnormal conditions occur, the module automatically activates protection mechanisms to prevent damage to itself and the connected control equipment, enhancing system safety.

- Certifications: Has obtained multiple certifications such as UL 508, CE, and IEC 61010. It complies with international industrial standards and safety regulations, ensuring safety and reliability during product use.

- Installation Method: Adopts DIN rail mounting, which enables a simple and fast installation process, facilitating system assembly and maintenance for users.

III. Functional Features

(I) High Efficiency and Stability

The GE 8920-PS-DC boasts a conversion efficiency of up to 92%, meaning minimal energy loss during power conversion. This effectively lowers the equipment's operating temperature, reduces the risk of equipment failures caused by high temperatures, and enhances the overall system energy efficiency. At the same time, the stable 24VDC output provides continuous and reliable power for control equipment, ensuring that the control equipment is not disturbed by voltage fluctuations during operation. This guarantees the accurate operation of the automation system and improves the quality and efficiency of industrial production.

(II) Redundancy and Reliability

This power module supports N+1 redundant configuration, and this redundant design is key to ensuring the continuous operation of industrial systems. Under normal working conditions, multiple power modules operate simultaneously and share the load; when one module fails, the redundant module can be put into operation with instant seamless switching, ensuring no interruption to the system power supply. This function is of vital significance for industrial scenarios with extremely high requirements for production continuity, such as the petrochemical and power industries. It can effectively avoid production downtime and significant economic losses caused by power supply failures.

(III) Flexible Adaptability

The wide input voltage range of 18-72VDC allows the GE 8920-PS-DC to adapt to different industrial DC power supply environments. Whether in small industrial equipment with relatively low voltage or large industrial control systems with higher voltage, this module can operate normally without additional voltage conversion equipment. This simplifies the system wiring and configuration process and reduces the difficulty and cost of system integration.

(IV) Safety Protection

Comprehensive protection functions are a major highlight of the GE 8920-PS-DC. When the system encounters abnormal conditions such as overcurrent, overvoltage, overtemperature, or short circuit, the module quickly activates protection mechanisms, automatically cutting off the output or taking other protective measures to prevent damage to itself and the connected control equipment. This not only improves the safety and reliability of the equipment but also reduces equipment maintenance costs and fault troubleshooting time.

(V) Convenient Integration and Maintenance

The modular design enables the GE 8920-PS-DC to be seamlessly integrated with GE's controller series such as ControlLogix and Mark VIe, facilitating the construction of industrial automation systems. Meanwhile, the hot-swappable replacement feature allows the module to be replaced without shutting down the entire system when a fault occurs. This significantly shortens system downtime and improves the maintainability and availability of the system.

IV. Application Scenarios

(I) Petrochemical Industry

In petrochemical production facilities, the GE 8920-PS-DC provides stable and reliable power supply for the control modules and I/O (Input/Output) cards of DCS systems. The petrochemical production environment is complex and hazardous, requiring extremely high reliability of equipment. The redundant design of this power module ensures that the system can continue to operate normally when a power module fails, avoiding production accidents caused by power supply interruptions and safeguarding the continuous progress of chemical production and personnel safety.

(II) Power Industry

In power substation automation systems, the GE 8920-PS-DC supplies power to key equipment such as protective relays and measurement and control devices. The stable operation of the power system is related to the electricity safety of the entire society, and power grid fluctuations may cause damage to equipment. The protection functions of this module, such as overtemperature and overvoltage protection, can effectively protect the equipment from damage when abnormalities occur in the power grid, ensuring the safe and stable operation of the substation and the continuous supply of electricity.

(III) Metallurgical Industry

In the control systems of metallurgical processes, the GE 8920-PS-DC plays an important role in power supply. The metallurgical production environment is usually characterized by high temperatures and high dust levels, requiring high environmental adaptability of power supply equipment. This module can operate stably under harsh environmental conditions, providing reliable power for various equipment in the metallurgical control system and ensuring the smooth progress of the metallurgical production process.

(IV) Mining Industry

In the control systems of mining machinery and equipment, the GE 8920-PS-DC provides stable power support. The mining operation environment is complex and variable, and equipment often needs to operate in remote and harsh conditions. The wide input voltage range and robust design of this module enable it to adapt to the power supply environment and working conditions in mines, ensuring the normal operation of the control systems of mining machinery and equipment and improving the safety and efficiency of mining production.

V. Common Faults and Troubleshooting Methods

(I) Abnormal Output Voltage

Possible Causes

- The input voltage exceeds the normal range of 18-72VDC, preventing the module from converting the voltage normally.

- Internal circuit faults of the module, such as damaged power devices or aged capacitors.

- Excessive load, exceeding the maximum output current of 20A of the module, resulting in a drop in output voltage.

Troubleshooting Methods

- Use a multimeter to detect the input voltage and ensure it is within the range of 18-72VDC. If the input voltage is abnormal, check the front-end power supply equipment and adjust the input voltage to the normal range.

- If the input voltage is normal, check the load condition and calculate whether the total load current exceeds 20A. If the load is excessive, appropriately reduce the load or add a power module for current shunting.

- If both the input voltage and the load are normal, there may be an internal circuit fault in the module. It is recommended to replace the module or contact professional maintenance personnel for repair.

(II) Module Overtemperature Protection

Possible Causes

- The working environment temperature is too high, exceeding the module's operating temperature range of -25℃ to +70℃.

- The module operates under full load for a long time, resulting in severe self-heating.

- Blockage of the module's heat dissipation channels, leading to poor heat dissipation.

Troubleshooting Methods

- Check the working environment temperature. If the environment temperature is too high, take cooling measures (such as installing cooling fans or air conditioners) to control the environment temperature within the normal range.

- Distribute the load reasonably to avoid the module operating under full load for a long time. If the load remains large, consider adding redundant modules to share the load.

- Clean the dust and debris around the module to ensure the heat dissipation channels are unobstructed and improve the module's heat dissipation effect.

(III) Abnormal Redundancy Switching

Possible Causes

- Improper setting of redundancy configuration parameters, preventing normal communication and switching between modules.

- Loose or poor contact of the connection lines between redundant modules.

- A hidden fault in one of the modules, affecting the redundancy switching function.

Troubleshooting Methods

- Check the redundancy configuration parameters to ensure they are set correctly and meet the system requirements. Reconfigure the parameters with reference to the product manual.

- Check the connection lines between redundant modules, reinsert the lines to ensure firm connection. If the lines are damaged, replace them in a timely manner.

- Conduct a one-by-one inspection of the redundant modules to identify any hidden faults. If a faulty module is found, replace it promptly.

(IV) Communication Faults (If Equipped with a Communication Interface)

Possible Causes

- Loose connection, poor contact, or damage to the communication lines.

- Inconsistent communication parameter settings (such as baud rate and protocol) that do not match the upper computer.

- Damage to the module's communication interface.

Troubleshooting Methods

- Check whether the communication lines are firmly connected and reinsert the communication lines. Use a multimeter to detect whether the lines have open circuits or short circuits. If the lines are damaged, replace them.

- Verify the communication parameters to ensure they are completely consistent with those of the upper computer, including baud rate and protocol.

- If both the communication lines and parameters are normal, the module's communication interface may be damaged. Contact professional maintenance personnel to replace the interface or the module.