Description

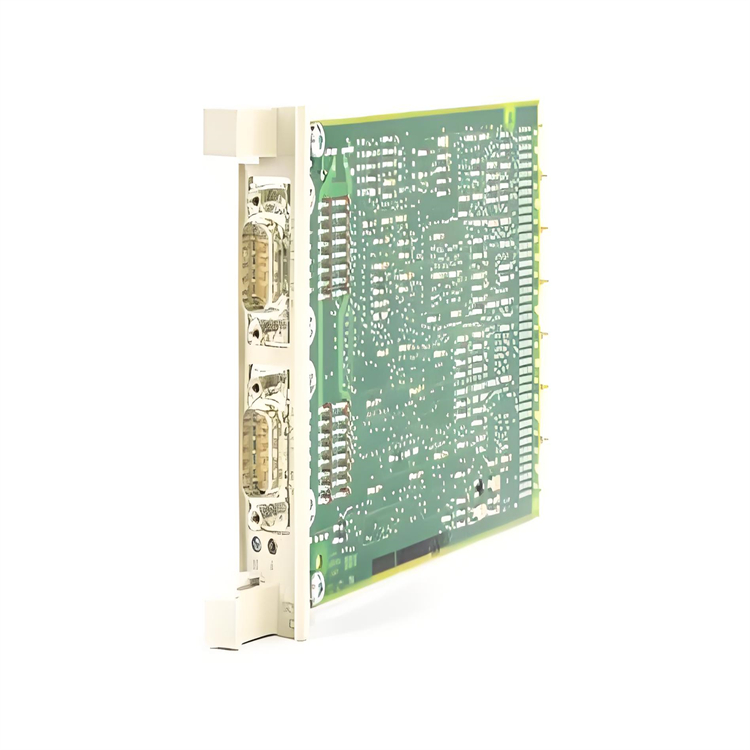

ABB SD821 3BSC610037R1

I. Overview

ABB SD821 3BSC610037R1 is an AC-DC power supply module, with its core positioning as a compact and stable power supply unit for industrial automation control systems. Designed specifically for precision control scenarios, this module supports manual switching between two input voltage ranges: 115V AC and 230V AC, and outputs stable 24V DC power with a rated output current of 2.5A. Adopting a DIN rail mounting method with a width of only 50mm, it features a compact structure and easy integration. It is compatible with mainstream DCS systems such as ABB System 800xA and high-precision tension control systems, and can directly provide pure and reliable power support for controllers, I/O modules, tension controllers and other equipment. It is a key power component to ensure the stable operation of automation systems in industries such as textiles, printing, steel and papermaking.

II. Core Features

Manual Switching Between Dual Voltage Ranges: Supports two input voltages, 115V AC and 230V AC, with the voltage range selected manually via the switch on the module. It can accurately adapt to the grid standards of different countries and regions, providing a flexible power supply solution for cross-regional equipment deployment without the need for additional transformers.

High-precision and Stable Output: Rated output of 24V DC power with a maximum output current of 2.5A, the output voltage accuracy can reach ±0.5% with low ripple and strong stability. It can provide pure power for high-precision equipment such as tension controllers, ensuring low drift and high response performance of the system.

Redundant Expansion and Multiple Protections: Can be connected with SS82x series voting units to build a redundant power supply system. When the main module fails, the standby module quickly switches to take over the power supply, ensuring power supply continuity. Built-in overcurrent and overvoltage protection circuits, combined with 500V AC electrical isolation design, can effectively resist power supply abnormalities and electromagnetic interference, protecting the safety of the module and subsequent equipment.

Compact and Easy Installation: Adopts standard DIN rail mounting with a width of only 50mm and a net weight of 0.5kg, which can efficiently utilize the space of the control cabinet, especially suitable for high-density integration scenarios. The modular structural design simplifies the installation and disassembly process, facilitating later maintenance, upgrading and component replacement of the system.

- Industrial-grade Environmental Adaptability: Complies with industrial Electromagnetic Compatibility (EMC) standards with excellent anti-interference capability. It can operate stably in a wide temperature range of -25℃~70℃ and a humidity range of 5%~95% (non-condensing), adapting to harsh industrial sites with heavy dust, large temperature fluctuations and severe electromagnetic interference.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB SD821 3BSC610037R1 |

| Product Type | Industrial-grade AC-DC Power Supply Module |

| Input Voltage | 115V AC/230V AC, manual switch selection; Allowable fluctuation range ±10% |

| Maximum Input Current | 25A |

| Output Parameters | DC 24V, rated output current 2.5A, voltage accuracy ±0.5%, rated power 60W |

| Mounting Method | DIN Rail Mounting |

| Dimensions | Width 50mm, overall dimensions approximately 120mm (H) × 80mm (D) × 50mm (W) |

| Product Weight | Net weight 0.5kg, shipping weight 2kg |

| Operating Environment | Temperature -25℃~70℃, relative humidity 5%~95% (non-condensing), protection class IP20 |

| Protection and Isolation | Built-in overcurrent and overvoltage protection; Electrical isolation voltage 500V AC (1 minute) |

| Redundant Configuration | Supports connection with SS82x series voting units to realize redundant power supply |

IV. Working Principle

The core working principle of the ABB SD821 3BSC610037R1 module is a closed-loop power supply process of voltage range switching - rectification and filtering - precise voltage regulation - protection and feedback. Through the coordination of internal circuits, it realizes the conversion from AC input to stable DC output, balancing power supply accuracy, safety and reliability. The specific working process can be divided into four core stages:

Stage 1: Voltage Range Selection and Input PreprocessingAccording to the on-site grid standard, select the 115V AC or 230V AC input voltage range via the manual switch. After receiving the corresponding voltage, the module filters out interference clutter and surge signals in the power grid through the input filter circuit, suppresses voltage fluctuations, and provides a relatively pure AC signal for the subsequent circuits.

Stage 2: Rectification and Power ConversionThe preprocessed AC signal is converted into DC power through the built-in rectifier circuit, and then the power conversion unit optimizes the energy conversion efficiency, reduces energy consumption and heat generation, and adjusts the voltage to a range close to the target value of 24V DC, laying the foundation for precise voltage regulation.

Stage 3: Precise Voltage Regulation and OutputThe converted power signal enters the core voltage regulation unit. The output voltage is stabilized at the rated value of 24V DC through a high-precision feedback adjustment mechanism, with the voltage accuracy controlled within ±0.5%. At the same time, the ripple is further filtered out to ensure the pure and stable output power supply, meeting the power supply requirements of high-precision equipment.

V. Common Fault Troubleshooting

1. No Module Output, Power-off of Subsequent Equipment

2. Unstable Output Voltage, Drift of High-precision Equipment

3. Switching Failure After Redundant Configuration, Power Supply Interruption