Description

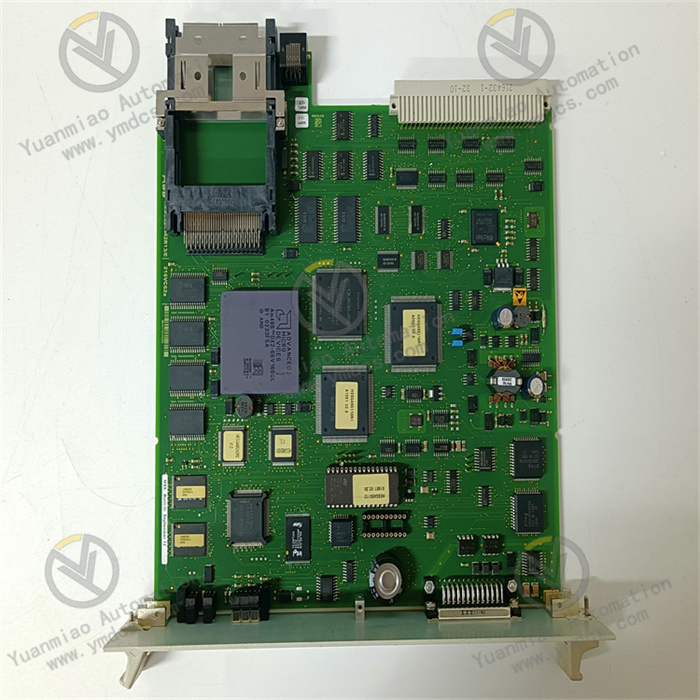

GE IS220PSVOH1B

I. Overview

IS220PSVOH1B retains a compact and robust structure, with dimensions still at 120mm×80mm×40mm (compatible with the original installation space), but its core components have been fully upgraded: the processor board adopts a 32-bit high-performance MCU (with a 30% higher computing speed than the previous generation), supporting more complex control algorithms; 2 additional servo drive status acquisition channels are added (for monitoring drive temperature and current); the accuracy of the on-board temperature sensor is improved to ±0.5℃ (compared with ±1℃ of the previous generation), enabling more accurate capture of the module's internal temperature rise; the flash memory capacity is expanded from 16MB to 32MB, supporting the storage of more comprehensive fault logs and control programs; the PCB coating is upgraded to a thickened conformal coating (with thickness increased from 20μm to 30μm), enhancing chemical corrosion resistance; "DRV 1/DRV 2" drive status lights are added to the front-panel LED indicators, allowing maintenance personnel to intuitively judge the operating status of the servo drive; at the same time, it retains two installation methods: standard 35mm guide rail installation and screw fixing, which is compatible with both old and new control cabinet layouts and reduces the cost of upgrade and replacement.

II. Technical Parameters

1. Electrical Interface and Control Parameters

| Parameter Category | Specific Specifications | Difference Comparison with Model 1A |

|---|---|---|

| Ethernet Interface | Supports 2 I/O Ethernet networks (redundant design) with a communication rate of 100Mbps; added Ethernet link quality monitoring (packet loss rate ≤0.1%) | Added link quality monitoring to improve communication reliability |

| Servo Valve Control | Controls 2 servo valve position loops with an adjustment accuracy of ±0.005mm (vs. ±0.01mm of the previous generation); supports servo valve dynamic response optimization (response time ≤0.5ms) | 50% higher accuracy and 20% faster response speed |

| Input Type | 8-channel LVDT input (resolution: 0.0005mm, vs. 0.001mm of the previous generation); 2-channel pulse rate input (supports a maximum pulse frequency of 1MHz, vs. 500kHz of the previous generation); 2 additional servo drive status inputs (temperature: -20℃~120℃, current: 0-5A) | Doubled LVDT resolution, increased pulse frequency, and added drive monitoring |

| Output Capability | 2-channel control output (0-10V DC/4-20mA) with an output accuracy of ±0.05% FS (vs. ±0.1% FS of the previous generation); supports output signal overload protection (maximum current: 30mA) | 50% higher output accuracy and added overload protection |

2. Diagnostic and Configuration Parameters (New Functions Marked)

| Parameter Category | Specific Specifications | New/Optimized Functions |

|---|---|---|

| Fault Diagnosis Function | Basic diagnosis: faults in power supply, network, processor, and servo loop (response time ≤30ms, vs. ≤50ms of the previous generation); new diagnosis: servo drive overheating (threshold: 90℃), drive overcurrent (threshold: 5A), and LVDT signal drift (alarm when deviation exceeds 5%) | 40% faster diagnostic response and 3 new types of fault diagnosis |

| Automatic Reconfiguration | Supports automatic reconfiguration with ToolboxST V11.0 and above (the previous generation supports V10.0+); added "configuration backup/restore" function for one-click export of configuration files | Compatible with new software versions and added configuration backup |

| Log Storage | Can store up to 500 recent fault logs (vs. 200 of the previous generation); each log includes a timestamp (accuracy: 1ms), fault type, and key parameters at the time of the fault (e.g., servo valve position, drive temperature) | Doubled log capacity and added parameter recording |

| Configuration Method | Retains graphical configuration via Control System Toolbox; added "Quick Configuration Wizard" for beginners to complete basic parameter settings (e.g., LVDT range, servo valve type) step by step | Added Quick Configuration Wizard to lower the operation threshold |

3. Environmental Adaptability Parameters (Enhanced Features Marked)

| Parameter Category | Specific Specifications | Enhancement Direction |

|---|---|---|

| Operating Temperature | -5℃~65℃ (vs. 0℃~60℃ of the previous generation); optimized low-temperature startup performance (startup time ≤3s at -5℃, vs. ≤5s of the previous generation) | Expanded wide temperature range and faster low-temperature startup |

| Storage Temperature | -40℃~85℃ (same as the previous generation), but with improved temperature resistance of components (capacitor temperature resistance: -55℃~125℃, vs. -55℃~105℃ of the previous generation) | Enhanced temperature resistance of components and extended storage life |

| Relative Humidity | 5%~95% (no condensation); added humidity over-limit alarm (alarm triggered when humidity ≥90%) | Added humidity alarm to prevent moisture-related risks in advance |

| Electromagnetic Compatibility | Complies with EN 55022 Class A; upgraded immunity: ESD ±15kV air discharge (vs. ±8kV of the previous generation), EFT ±4kV for power ports (vs. ±2kV of the previous generation) | Significantly improved anti-interference capability |

4. Physical Characteristic Parameters (Detailed Optimization Marked)

| Parameter Category | Specific Specifications | Optimization Details |

|---|---|---|

| Installation Method | 35mm guide rail installation/screw fixing (same as the previous generation), but the guide rail clip material is upgraded to stainless steel (vs. galvanized steel of the previous generation) for improved rust resistance | Upgraded clip material to adapt to high-humidity environments |

| Weight | Approximately 0.55kg (vs. 0.5kg of the previous generation); the weight increase is due to the thickened PCB coating and additional components | Slightly increased weight with enhanced reliability |

| PCB Coating | Thickened conformal coating (30μm, vs. 20μm of the previous generation); made of high-temperature-resistant polyimide, with 50% improved chemical corrosion resistance | Thickened coating for enhanced corrosion resistance |

| Indicator Light Configuration | Retains ENET 1/2, power, ATTN, and ENA 1/2 lights; added DRV 1/2 lights (green: normal, yellow: warning, red: fault) | Added drive indicator lights for more intuitive status display |

III. Functional Characteristics

1. Ultra-High-Precision Servo Control and Dynamic Response Optimization

- Micron-Level Adjustment Accuracy: With a servo valve opening control accuracy of ±0.005mm, it can precisely adjust the fuel flow in the fuel valve control of a 150MW gas turbine, increasing the thermal efficiency of the gas turbine by 0.3 percentage points and saving over 100,000 cubic meters of natural gas annually.

- Faster Dynamic Response: With a servo response time of 0.5ms and combined with the "predictive adjustment algorithm", when there is a sudden change in grid load (e.g., a sudden increase of 20MW load), the module can predict the servo valve adjustment amount in advance to avoid overshoot (overshoot reduced from 5% to 2%), ensuring stable turbine speed.

- High-Fidelity Processing of LVDT Signals: With an LVDT resolution of 0.0005mm, it can capture micro-vibrations of the servo valve core (e.g., high-frequency vibrations of 0.001mm). In a steam turbine system, by analyzing the vibration frequency, it detected valve core wear 20 days in advance (vibration frequency increased from 50Hz to 80Hz), avoiding valve core jamming faults.

2. Full-Lifecycle Monitoring of Servo Drives

- Real-Time Monitoring of Multiple Parameters: The 2-channel drive status input can simultaneously monitor temperature (accuracy: ±0.5℃) and current (accuracy: ±0.01A). In the servo system of a petrochemical compressor, when the current of the wsvo drive slowly increased from 3A to 4.8A (threshold: 5A), the module triggered a "drive overload warning". After maintenance personnel cleaned the drive's heat dissipation channel, the current returned to normal, avoiding overheating damage.

- Trend Analysis and Life Prediction: By storing historical temperature/current data of the drive, it can generate trend curves to predict the remaining service life of the drive (e.g., with an annual temperature rise of 3℃, it is predicted to reach the threshold in 5 years). In the turbine system of a power plant, aging drives were replaced in advance based on trend analysis, avoiding sudden faults.

- Fault Linkage Protection: When the drive experiences overheating (exceeding 90℃) or overcurrent (exceeding 5A), the module immediately cuts off the output signal and activates the standby drive for switching, with a switching time of ≤100ms. This prevented blast furnace air cut-off caused by drive faults in the blast furnace blower system of an iron and steel plant (each hour of air cut-off would result in losses exceeding 500,000 yuan).

3. Enhanced Adaptability to Extreme Environments

- Wide Temperature Range and Optimized Low-Temperature Startup: With an operating temperature range of -5℃~65℃ and combined with a low-temperature startup preheating circuit, the module's startup time was reduced from 5s to 3s in the outdoor turbine control cabinet in northern winter (-5℃), avoiding control delays caused by low temperatures. In the high-temperature workshop in southern summer (65℃), the internal temperature of the module is 8℃ lower than the ambient temperature through optimized heat dissipation paths, ensuring stable operation of components.

- Strong Electromagnetic and Corrosion Protection: With ±15kV ESD air discharge protection and a thickened PCB coating, the module's communication bit error rate was ≤1×10⁻⁸ in the turbine system of a chemical industrial park (with high-frequency welding equipment nearby and electromagnetic interference of 15V/m), which is an order of magnitude lower than that of the previous generation. In coastal power plants (high salt spray environment), the thickened coating can resist salt spray corrosion, and the module has operated continuously for 3 years without PCB rust.

- Humidity Warning and Protection: When the ambient humidity ≥90%, the module triggers a humidity warning and uploads data via Ethernet. Maintenance personnel promptly turn on the dehumidification device of the control cabinet, avoiding circuit short-circuit faults caused by moisture in the turbine control system of a hydropower station (with 95% humidity in the rainy season).

4. Improved Efficiency of Intelligent Operation and Maintenance

- Visual Status and Log Management: With the newly added DRV 1/DRV 2 indicator lights and 500 fault logs, in the turbine cluster of a large factory, maintenance personnel can quickly locate faulty drives through the indicator lights. Combined with detailed logs (including temperature and current at the time of the fault), the troubleshooting time was reduced from 2 hours to 30 minutes.

- Quick Configuration and Backup: With the "Quick Configuration Wizard" and configuration backup function, when replacing the module, novice maintenance personnel can complete basic configuration within 10 minutes through the wizard, and parameter restoration can be achieved with one click using backup files, avoiding configuration errors. In the system upgrade of a petrochemical plant, the configuration time for 10 modules was reduced from 1 day to 2 hours.

- Remote Diagnosis and Firmware Upgrade: It supports remote reading of fault logs, parameter adjustment (e.g., servo valve accuracy compensation), and firmware upgrade via Ethernet. In cross-regional power plants, technical personnel at the headquarters can remotely upgrade the firmware of modules in different locations without on-site trips, saving more than 100,000 yuan in travel expenses annually.