Description

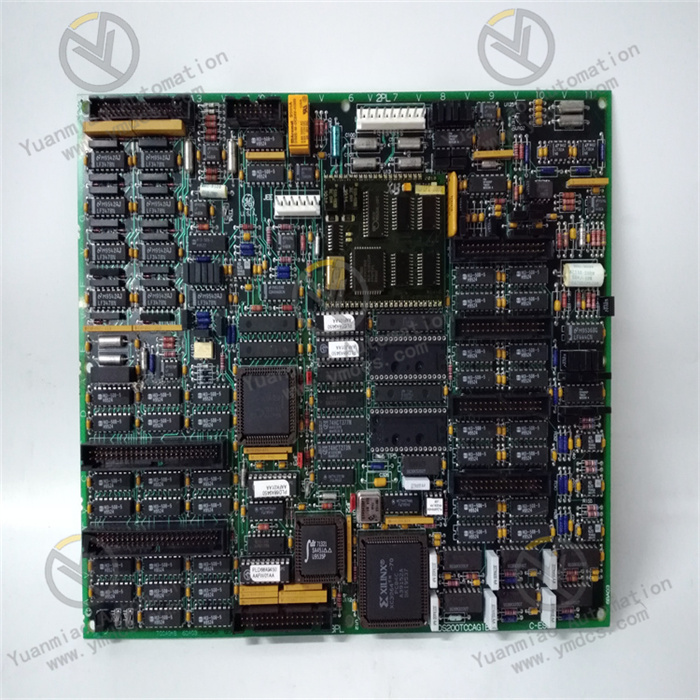

GE DS200SDCCF1AFD

Overview: GE DS200SDCCF1AFD is likely an input/output card, associated with the GE Speedtronic Mark V turbine control unit. It plays an important role in signal processing and transmission in industrial automation systems. It can be used to connect various sensors and actuators, enabling signal interaction between the control system and external equipment. It is widely applied in industries such as electric power, oil and gas, and chemical engineering, for the control and monitoring of equipment like steam turbines and gas turbines.

Functional Features:

- Precise Control: It can achieve precise control of motor speed and torque, with a speed control accuracy of up to ±0.1% and a torque control accuracy of ±5%, which can meet various industrial application requirements.

- Reliable Protection: It has multiple protection functions such as overvoltage, overcurrent, and short circuit protection, which can effectively protect the motor from damage and improve the stability and reliability of the system.

- Real-time Monitoring: It supports real-time monitoring of parameters such as temperature, pressure, and flow rate, making it convenient for operators to timely understand the operating status of equipment and detect potential problems.

- Strong Compatibility: It supports multiple communication protocols such as RS-232, facilitating integration with other equipment and adapting to different industrial control system architectures.

- Easy Maintenance: Adopting a modular design, it has a compact structure, which is convenient for installation and disassembly, and easy to maintain, thus reducing equipment downtime.

Technical Parameters:

- Power Parameters: The input voltage is usually 24VDC, the output voltage can also be 24VDC, the input current is approximately 10mA, and the output current can reach 500mA.

- Communication Interfaces: It may support communication interfaces such as Ethernet and RS-232/485 to meet different communication needs.

- Operating Environment: The operating temperature range is generally -40°C to +70°C, and the operating humidity is 0% to 95% RH (non-condensing), which can adapt to relatively harsh industrial environments.

- Installation Method and Dimensions: It is usually installed on a DIN rail, with dimensions possibly around 100mm x 70mm x 25mm and a weight of approximately 0.3kg, saving installation space.

Working Principle: This module receives signals from devices such as sensors through input channels, such as analog signals from temperature and pressure sensors, or digital signals from buttons and limit switches. After converting and processing these signals, it transmits them to the core processor of the control system. The processor analyzes and calculates the signals according to preset control logic and algorithms, and then sends the processing results to actuators through output channels, such as controlling the speed of the motor and the opening of the regulating valve. At the same time, the module may also exchange data with other devices through communication interfaces, upload its own status information to the monitoring system, or receive control commands from other devices to realize the coordinated operation of the entire system. In addition, the built-in protection circuit of the module will monitor electrical parameters in real-time. When abnormal situations such as overvoltage and overcurrent occur, it will promptly trigger the protection mechanism, cut off the relevant circuits, and protect the safety of the equipment.