Description

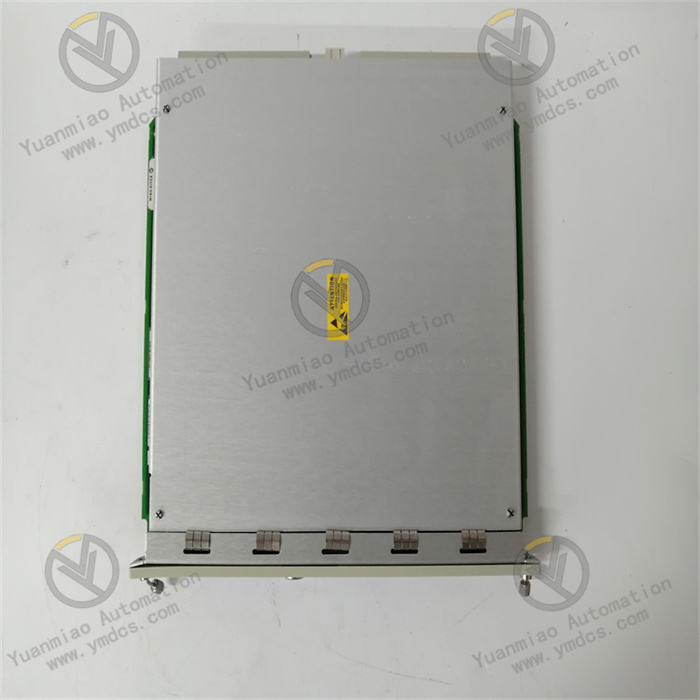

ABB PFSA140 3BSE006503R1

I. Basic Information

- Full Model: PFSA140 3BSE006503R1

- Series: Fieldbus adapter module of ABB Industrial IT System 800xA control system, belonging to the Process Field System (PFS) series, used to connect field devices and control systems.

- Purpose: As an interface between fieldbus and control systems, it supports multiple industrial communication protocols (such as Profibus DP, Modbus, etc.), enabling data collection and control of devices like sensors and actuators. It is suitable for automation scenarios in process industries (chemical, petroleum, power, pharmaceutical, etc.).

II. Core Functions and Features

Communication Protocol Support

- Supports Profibus DP V0 master/slave mode, connecting up to 126 slave devices (e.g., intelligent instruments, distributed I/O modules).

- Compatible with Modbus RTU protocol (optional for some models), supporting communication with third-party devices (e.g., frequency converters, PLCs).

- Supports hot-swapping to ensure replacing modules during system operation does not affect overall communication.

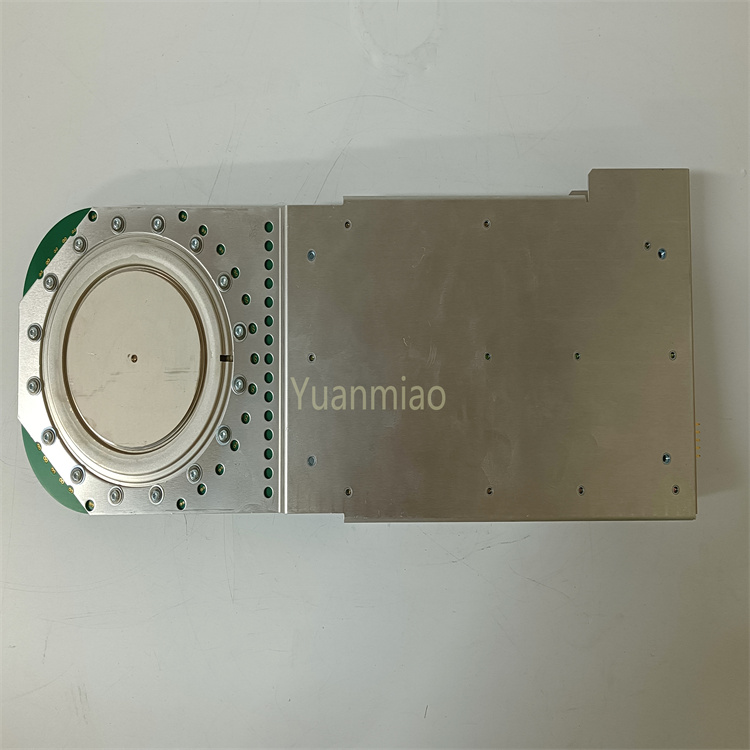

Electrical and Physical Characteristics

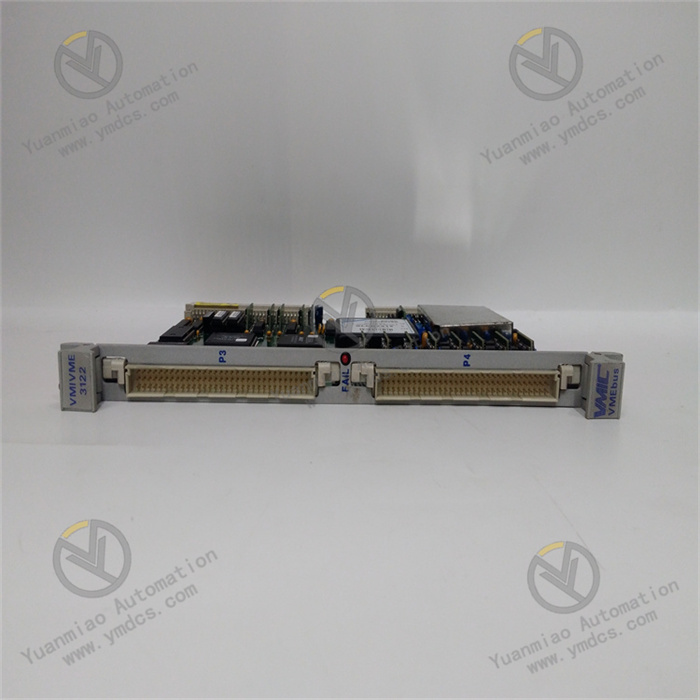

- Interface Type: Profibus interface uses 9-pin D-type connector, supporting shielded twisted-pair cables with a maximum communication rate of 12 Mbps.

- Isolation Design: Electrical isolation voltage ≥ 500V AC prevents field interference from affecting control system stability.

- Status Indication: Built-in LED indicators (e.g., RUN, FAULT, BUS ACTIVE) display module operation and communication status in real time.

Diagnosis and Redundancy Functions

- Supports channel-level fault detection (e.g., bus disconnection, slave communication failure), and reports alarms through the control system.

- Redundant modules (e.g., dual Profibus buses) can be configured in some application scenarios to enhance system reliability.

III. Technical Parameters (Refer to Official Manual)

| Parameter Dimension | Specific Indicators |

|---|---|

| Communication Protocol | Profibus DP V0 (master/slave), optional Modbus RTU |

| Maximum Number of Slave Stations | 126 (depending on communication rate) |

| Communication Rate | 9.6 kbps ~ 12 Mbps (adaptive) |

| Operating Voltage | DC 24V (±10%), power consumption ≤ 3W |

| Operating Temperature | -20℃ ~ +60℃, humidity 5%~95% (non-condensing) |

| Protection Level | Panel IP20 (needs to be installed in control cabinet) |

| Installation Method | DIN rail installation, compatible with ABB 800xA system racks |

IV. Application Scenarios

Process Industry Automation

- Chemical Production Lines: Connects pressure transmitters, temperature sensors, control valves, etc., to achieve data collection and control command issuance via Profibus bus.

- Power Systems: Docks with smart meters and relay protection devices to realize communication interconnection of substation automation systems.

Large Equipment Monitoring

- Metallurgical Industry: Connects blast furnace level meters and rolling mill speed sensors to transmit data to the central control system in real time.

- Pharmaceutical Equipment: Communicates with controllers of equipment such as mixing kettles and sterilizers to meet GMP compliance data recording requirements.

Distributed Control System (DCS)

- As the fieldbus hub of the 800xA system, it integrates dispersed field devices and reduces cable wiring complexity.

V. Installation and Usage Key Points

Hardware Installation

- Fix in the control cabinet using DIN rail, with a spacing ≥ 15mm from adjacent modules to ensure heat dissipation.

- Profibus bus needs to connect terminal resistors (terminal stations require 120Ω resistors), cables need to be twisted and shielded, and grounding resistance ≤ 1Ω.

Software Configuration

- Use ABB Control Builder M or 800xA Engineering software to configure module parameters (e.g., station address, communication rate, slave device mapping).

- Define input/output data mapping tables in the system to associate field device signals with controller variables.

Fault Troubleshooting

- If the LED displays "FAULT", check whether the bus cable connection, terminal resistors are normal, or whether the slave device is powered off.

- When communication is interrupted, use software diagnostic tools to check bus load rate (recommended ≤ 30%) to avoid communication delay caused by high load.

VI. Typical Supporting Equipment

- Controllers: ABB 800xA CPU modules (e.g., PM866, PM891).

- Field Devices: ABB PP846 distributed I/O modules, Siemens ET200M slaves, various Profibus protocol intelligent instruments.

- Auxiliary Modules: PFSP101 power module (powering PFS series), PFSK151 communication expansion module (for multi-bus protocol conversion).