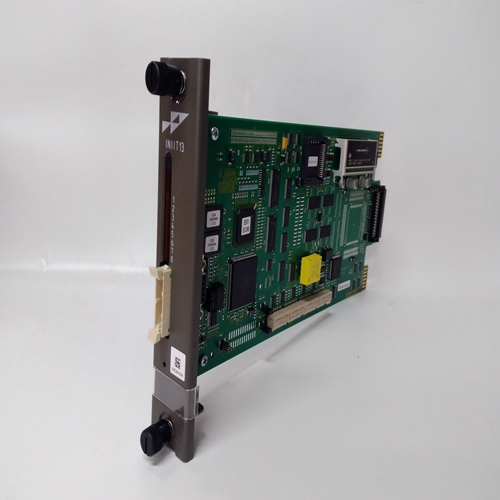

Description

GE IC693PWR322F

I. Overview

GE IC693PWR322F is a high-performance power supply module in the GE Fanuc 90-30 series, specially designed to provide stable and reliable power support for industrial automation control systems. In the field of industrial automation, stable power supply is the cornerstone to ensure the normal operation of the entire control system. With excellent performance and reliability, this module can continuously supply power to PLCs, I/O modules and other related equipment in complex industrial environments, ensuring that data transmission, logical operations and execution of control instructions between various devices are not affected by power fluctuations. It is an indispensable key component in industrial automation systems.

II. Technical Parameters

- Input Parameters: It supports a wide range of AC input voltages, usually 100-240V AC, 50/60Hz. This wide voltage input design enables it to adapt to the power grid voltage standards of different countries and regions, and can be flexibly applied in industrial scenarios worldwide. The input current varies according to the input voltage. Under the rated input voltage, the input current is about 1.5A-3A, which can meet the power demand of the module itself and the connected equipment.

- Output Parameters: It provides a variety of DC output voltages, mainly including 5V DC and 24V DC. The 5V DC output current can reach 10A, and the 24V DC output current can reach 2A, which can provide sufficient power for 90-30 series CPU modules, I/O modules, etc. The output voltage accuracy is high. The accuracy of 5V DC output is usually within ±5%, and that of 24V DC output is within ±10%, ensuring stable voltage for the equipment and avoiding damage to the equipment caused by voltage fluctuations.

- Efficiency and Power Consumption: It has high conversion efficiency, which can reach more than 85% under rated load, effectively reducing energy loss and operating costs. Under no-load or light-load conditions, the power consumption is low, meeting the requirements of modern industry for energy-saving equipment.

- Physical Parameters: The module has a compact size, approximately 110mm×160mm×80mm, and adopts a standard rail mounting method, which is convenient for compact arrangement and installation with other modules in the control cabinet, saving installation space. The overall weight is light, about 0.5kg, facilitating installation and maintenance operations.

- Environmental Parameters: The operating temperature range is 0°C to 60°C, and it can work stably in the common temperature environment of industrial sites, whether it is a high-temperature production workshop or a relatively cool control room, it can output power normally. The relative humidity adaptation range is 5%-95% (non-condensing), which can cope with humid industrial environments and prevent circuit faults caused by humidity problems. At the same time, it has a certain anti-vibration and anti-shock capability, meeting the environmental adaptability standards of industrial-grade equipment.

III. Functional Characteristics

- Stable and Reliable Output Performance: It adopts advanced power conversion technology and voltage stabilizing circuit, which can effectively suppress the impact of input voltage fluctuations and load changes on the output voltage, ensuring the stability of the output voltage. Even when the industrial power grid voltage fluctuates instantaneously or the equipment load changes, it can adjust quickly to ensure that the output voltage is within the specified accuracy range, providing continuous and stable power for the connected equipment, and reducing equipment failures caused by unstable power supply.

- Multiple Protection Functions: It has a complete protection mechanism, including overcurrent protection, overvoltage protection, short-circuit protection and overheating protection, etc. When the output current exceeds the rated value, the overcurrent protection function will start quickly to limit the output current or cut off the output, preventing damage to the module and connected equipment due to overcurrent; overvoltage protection can play a role when the output voltage rises abnormally, protecting the equipment from high-voltage impact; short-circuit protection can immediately cut off the power output when a short-circuit fault occurs at the output end, avoiding the module being burned due to excessive short-circuit current; overheating protection will automatically reduce the output power or stop the output when the internal temperature of the module is too high, and restart after the temperature returns to normal, ensuring the service life of the module.

- Convenient Status Indication: It is equipped with multiple status indicators, such as power input indicator, 5V DC output indicator, 24V DC output indicator and fault indicator, etc. Through the on-off status of the indicators, technicians can intuitively understand the working status of the module, such as whether there is input power, whether each output voltage is normal, whether there is a fault, etc., which is convenient for quickly judging the operation of the module during daily inspection and fault Investigation,and improving maintenance efficiency.

- Compatibility and Expandability: It is specially designed for GE 90-30 series PLC systems, and has good compatibility with CPU modules, I/O modules of this series, etc., and can be seamlessly integrated into the system. At the same time, the output capacity of the module can meet the power supply requirements of a certain number of I/O modules and other equipment. If the system needs to expand more equipment, it can be realized by adding this type of power module or matching with power modules of other powers, which has good expandability.

- Industrial-Grade Durable Design: The shell is made of high-strength, corrosion-resistant industrial-grade materials, which has good mechanical strength and protective performance, and can withstand vibration, impact and dust pollution in industrial environments. The internal circuit uses high-quality electronic components, which have passed strict industrial environment tests, ensuring the reliability and stability of the module during long-term continuous operation, and reducing equipment failure rate and maintenance costs.

IV. Common Faults and Solutions

- No Output Voltage

- Phenomenon: Both 5V DC and 24V DC outputs have no voltage, the corresponding output indicators are not on, and the connected equipment cannot work normally.

- Possible Causes: The input power is not connected or the input voltage is abnormal; the internal input circuit of the power module is faulty, such as fuse blown, rectifier bridge damaged, etc.; the internal main circuit of the module is faulty and cannot perform power conversion.

- Solutions: Check whether the connection of the input power is firm, use a multimeter to measure whether the input voltage is within the specified input range of the module, and ensure that the input power is normal; if the input power is normal, check whether the internal fuse of the module is blown, if it is blown, replace it with a fuse of the same specification (note that first eliminate the fault causes leading to the fuse blowing, such as short circuit, etc.); if the fuse is normal or blows again after replacement, there may be an internal circuit fault, and it is necessary to contact professional maintenance personnel for repair or replace the module.

- Unstable Output Voltage

- Phenomenon: The output voltage fluctuation exceeds the specified accuracy range, causing the connected equipment to work unstable, such as indicator flashing, data transmission errors, etc.

- Possible Causes: The input voltage fluctuation is too large, exceeding the adaptation range of the module; the load at the output end is unstable or too large, exceeding the rated output current of the module; the internal voltage stabilizing circuit of the module is faulty, such as voltage regulation chip damage, filter capacitor aging, etc.

- Solutions: Use a voltage stabilizer to stabilize the input voltage, ensuring that the input voltage is within the rated input range of the module; check the load at the output end, avoid excessive load or frequent fluctuations, if the load exceeds the module capacity, replace it with a higher-power power module; if the input voltage and load are normal, there may be a fault in the internal voltage stabilizing circuit, and the module needs to be repaired or replaced.

- Frequent Activation of Overcurrent Protection

- Phenomenon: The module frequently enters the overcurrent protection state, the output current is limited or the output is interrupted, and the equipment shuts down frequently.

- Possible Causes: The equipment connected to the output end has a short-circuit fault, causing the output current to increase instantaneously; some equipment has internal faults, and the working current increases abnormally; the overcurrent protection circuit of the module is too sensitive or faulty.

- Solutions: Check the equipment connected to the output end one by one, disconnect all equipment, then connect the equipment step by step, find out the equipment with short circuit or abnormal current, and repair or replace it; if all equipment is normal, there may be a fault in the overcurrent protection circuit, and it is necessary to repair the protection circuit of the module or replace the module.

- Activation of Overheating Protection

- Phenomenon: During operation, the module enters the overheating protection state due to excessive temperature, the output power is reduced or the output is stopped, and resumes work after the temperature drops, and this repeats.

- Possible Causes: The working environment temperature of the module is too high, exceeding its working temperature range; the heat dissipation channel of the module is blocked, such as excessive dust accumulation on the surface, affecting heat dissipation; the internal cooling fan (if any) of the module is faulty, and the heat dissipation capacity is reduced.

- Solutions: Improve the working environment of the module, reduce the ambient temperature, such as strengthening the ventilation of the control cabinet, installing cooling fans, etc.; regularly clean the dust on the surface of the module to ensure that the heat dissipation channel is unobstructed; check whether the cooling fan is working normally, if it is faulty, replace the fan to enhance the heat dissipation effect.