Description

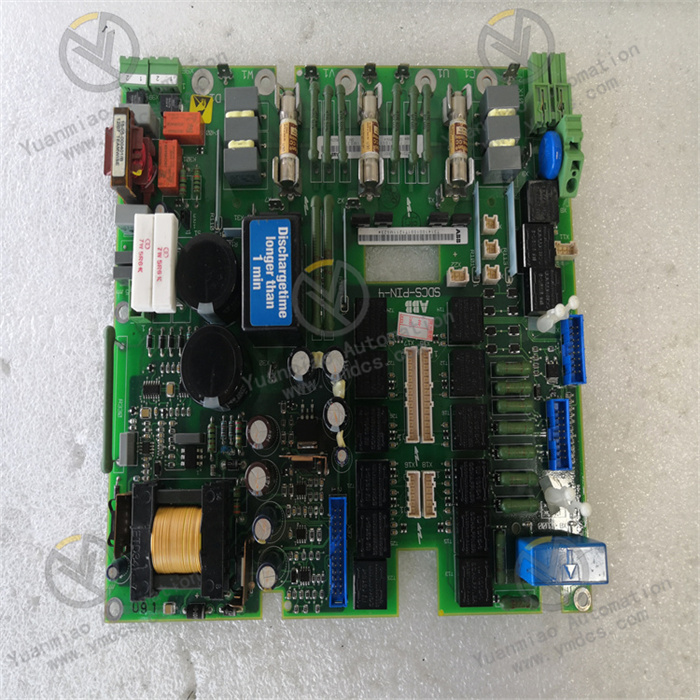

ABB CI627A 3BSE017457R1

Functional Features

Powerful I/O and Processing Capability: Equipped with multiple input channels, it can receive and process analog signals (such as voltage, current) and digital signals (such as switch states, counter inputs, etc.). It provides 2048 I/O ports, expandable to 4096 I/O ports, with a processing speed of 200 MHz and 1 MB of RAM to meet complex control requirements.

Support for Multiple Communication Protocols: Supports various communication protocols such as EtherNet/IP, Modbus TCP/IP, PROFINET, and RS485, facilitating integration with other devices and systems.

Abundant Advanced Functions: Includes powerful logic functions, such as complex algorithms and control functions, as well as report capabilities for automatic report saving, capable of generating over 70 unique reports for data tracking and analysis.

Performance Parameters

- Input Voltage: 24VDC

- Output Current: 20mA

- Output Power: 480mW

- Output Voltage: 24VDC

- Power Consumption: <1W

- Operating Temperature Range: -25°C to +60°C

Advantages and Characteristics

- High Stability and Reliability: Designed to withstand various industrial environments, ensuring stable operation.

- Easy Programming and Installation: Facilitates configuration and maintenance by technicians.

- Rich Interfaces: Equipped with multiple communication interfaces for communication and data exchange with different industrial devices and systems.

Application Scenarios

- Automated Manufacturing: Connects various production line devices to achieve automated control and monitoring of production processes.

- Process Control: Monitors and controls process parameters in industries such as chemicals, pharmaceuticals, oil, and gas.

- Power Systems: Acquires and processes various data in power systems to monitor and protect power equipment.

- Building Automation: Controls and manages building equipment such as lighting, air conditioning, and elevators.

- Logistics and Warehousing: Enables automated operation of logistics equipment and monitoring of warehousing environments.

How to Troubleshoot Faults in ABB CI627A Modules?

I. Common Fault Types and Solutions

- Module Power Failure (Abnormal PWR Light)

- Fault Symptoms:

- PWR light off: Module not powered or power supply abnormal.

- PWR light flashing: Caused by power fluctuations or poor backplane contact.

- Troubleshooting Steps:

- Check Power Supply:

Confirm the AC 800M backplane power is normal (24V DC) using a multimeter to measure the voltage at the backplane slot. If the module is externally powered (if applicable), check the external power supply. - Hardware Contact:

Re-plug the module to ensure good contact with the backplane and secure latching. Inspect the backplane bus for oxidation or damage, and clean or replace the backplane if necessary. - Redundancy Configuration:

If the system supports redundant power, switch to the backup power for testing. - Communication Failure (Abnormal COM Light or Module Not Recognized)

- Fault Symptoms:

- COM light off or constantly on: Communication interruption between the module and controller.

- The module appears "offline" or "unrecognized" in controller software (e.g., Control Builder M).

- Troubleshooting Steps:

- Software Configuration Verification:

Ensure the module type (CI627A) is correctly added in Control Builder M, and the configured address (e.g., slot number) matches the hardware. Check if the project has been downloaded to the controller, and try re-downloading the configuration. - Backplane Communication Test:

Move the module to another slot to rule out backplane bus faults. Compare the communication status with a normal module of the same type to confirm hardware damage. - Firmware Version:

Check if the controller firmware supports the CI627A module, and upgrade to the latest version if necessary (refer to ABB official documentation). - Abnormal Analog Input Signals (Data Errors or Out-of-Range)

- Fault Symptoms:

- Input values fluctuate, remain at maximum/minimum (e.g., 27648 or -27648), or display "NaN".

- Signals do not match actual physical quantities (e.g., 4 mA input from a pressure sensor shows 0%).

- Troubleshooting Steps:

- Signal Type Configuration:

Ensure module channel parameters match the actual signals (e.g., 4-20 mA, 0-10 V, thermocouple type, etc.). Check the "Range" and "Filter" settings for channels in Control Builder M. - Wiring and Cables:

Verify correct input signal wiring (e.g., differential/single-ended input) and secure terminal connections to avoid looseness or short circuits. For voltage signals, keep cables away from strong EMI sources (e.g., motors, variable frequency drives) and use shielded cables with single-point grounding. For thermocouples/thermal resistors, check for compensating wires and correct polarity. - Signal Source Testing:

Use a calibrator to input standard signals (e.g., 4 mA, 20 mA, 0 V, 10 V) directly to the module and observe readings. If readings are normal, the fault may lie with the field sensor or transmitter (further inspect sensor power supply and output characteristics). - Channel Damage:

Switch to a backup channel for testing. If the backup channel works, the current channel may be faulty and require module replacement. - Module Overheating or Environmental Faults

- Fault Symptoms:

- Excessive surface temperature on the module or false fault alarms due to environmental factors.

- Troubleshooting Steps:

- Environmental Conditions:

Ensure the operating temperature is within -20°C to +60°C, and avoid direct sunlight or poor ventilation in the control cabinet. Check if cabinet fans are operational to ensure air circulation and reduce internal temperature. - Vibration and Electromagnetic Interference:

Check if the module is securely installed to prevent loose wiring due to vibration. Keep it away from high-power equipment (e.g., transformers, variable frequency drives) to reduce EMI interference. - System Compatibility or Configuration Errors

- Fault Symptoms:

- Abnormal data during multi-module collaboration or incompatibility with third-party devices.

- Troubleshooting Steps:

- System Resource Conflicts:

Check for I/O address conflicts with other modules (e.g., overlapping input/output addresses). Ensure the controller’s memory and processing power can support the module’s sampling rate and channel count. - Cross-Device Integration:

When used with third-party sensors/transmitters, ensure their output signal ranges are within the CI627A’s supported range (e.g., configure 0-20 mA as 4-20 mA and calibrate offsets).

II. Advanced Maintenance and Replacement Procedures

- Online Hot-Swap (Caution Required)

- The module is disabled or removed from the software.

- Anti-static wrist straps are worn to avoid electrostatic damage.

- If the system supports redundant configuration, faulty modules can be replaced under power, but ensure:

- Procedure:

- Stop module data acquisition or disable channels in Control Builder M.

- Disconnect the faulty module’s wiring (if externally connected) and remove the module.

- Insert the new module, restore wiring, reconfigure, download the configuration, and test.

- Module Calibration and Firmware Upgrade

- Calibration:

Use ABB’s official tools (e.g., Calibration Tool) to perform zero-point and full-scale calibration for measurement accuracy. - Firmware Upgrade:

Update module firmware via Control Builder M or ABB service tools (e.g., Boot Loader) to resolve known bugs or compatibility issues (refer to official upgrade guides).

III. Fault Recording and Preventive Measures

- Fault Logging:

View fault codes in the controller (e.g., error messages in the diagnostic buffer) and use the CI627A Diagnostic Manual to locate issues. Record operation steps and environmental parameters (e.g., temperature, voltage) at the time of the fault for follow-up analysis. - Preventive Maintenance:

Regularly inspect module wiring tightness and clean control cabinet dust. Back up system configuration files to avoid loss during module replacement. Set up redundant modules (e.g., dual-channel hot standby) for critical channels to enhance system reliability.