Description

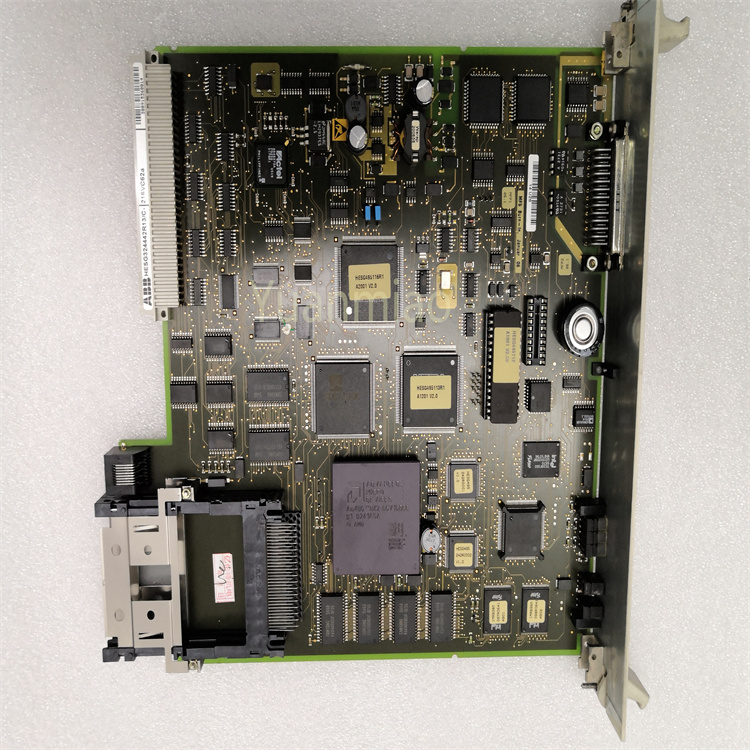

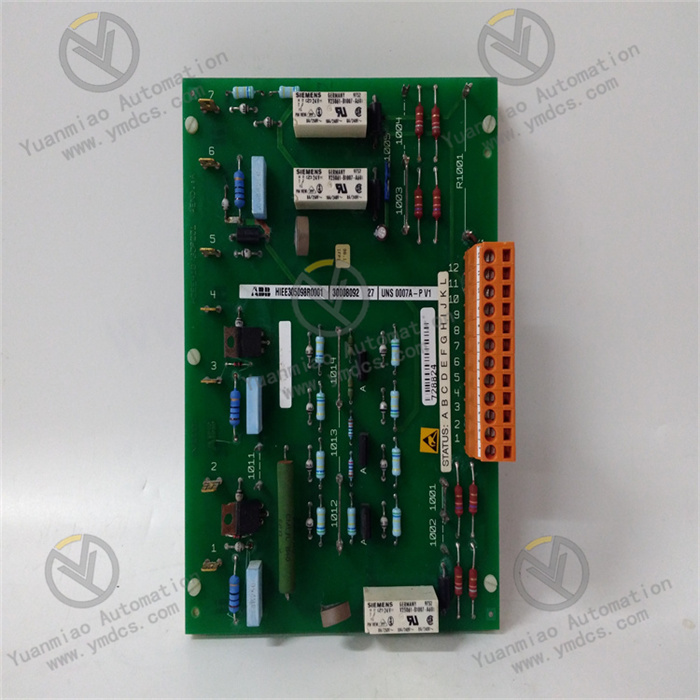

Meaning of Model Components: "HIEE" is generally a specific identification prefix for ABB's products, indicating that the product is from ABB. The part "410730P201" is likely the specific model code of the product, which contains relevant information such as the product type, specifications, version, etc. Different combinations of numbers and letters correspond to specific functions and characteristics. "UNS0007A-P" may be another number or classification identifier for the product, which may be related to the product series, application scenarios, installation methods, etc. "V1" clearly indicates that the product is version 1, and there may be updates to other versions in the future. Different versions may have differences in functions, performance, or compatibility. Speculation on Functional Characteristics: It may possess high-precision signal acquisition and processing capabilities to ensure accurate control and monitoring; it may support multiple communication protocols, facilitating data interaction with other devices and integration into automation systems; it may have reliable electrical isolation and anti-interference capabilities to adapt to the complex electromagnetic interference situations in industrial environments. Application Fields: It may be applied in industrial automation production lines to monitor and control various parameters in the production process; in the power system, it is used for the control and protection of power equipment; it may also play a role in the process control field, such as in the production processes of industries like chemical, petroleum, and natural gas.

Application Cases:

Industrial Robot Control: In industrial robot systems such as ABB Robots, this product can serve as part of the control module, responsible for processing the robot's motion control commands and receiving sensor feedback signals to ensure that the robot accurately performs various actions, such as welding, handling, assembly, and other tasks. For example, in the welding workshop of an automobile manufacturing factory, multiple industrial robots work in coordination. The HIEE410730P201 UNS0007A-P, V1 product helps the robots accurately complete the welding process of the automobile body, ensuring the welding quality and precision.

Distributed Control System (DCS): In large-scale industrial production processes, such as the distributed control systems in industries like chemical and power, it is used to achieve data collection, processing, and control of each production link. For instance, in a chemical production unit, it can collect various on-site process parameters, such as temperature, pressure, flow rate, etc., transmit the data to the central control unit for analysis and processing, and output control signals according to the preset control strategies to adjust the valve openings, pump speeds, etc. in the production process, so as to ensure the stable operation of the production process and improve production efficiency and product quality.

Large Servo Control System: It is applied in some large servo control systems that require high-precision position control and speed control, such as numerical control machine tools, textile machinery, and other equipment. Taking a numerical control machine tool as an example, this product can cooperate with the servo motor driver to precisely control the moving position and speed of the machine tool worktable, achieving high-precision machining of workpieces and meeting the processing technology requirements of complex parts.