Description

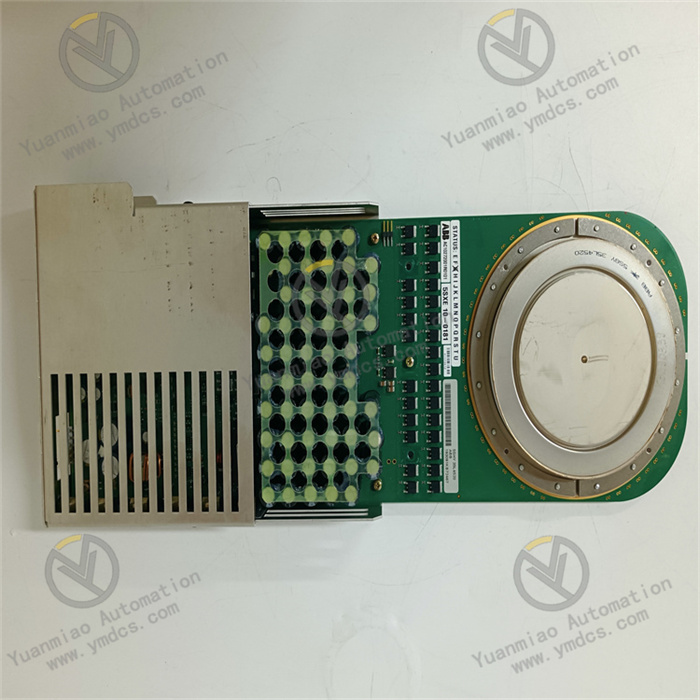

ABB CI630K02 3BSE011002R1

ABB CI630K02 3BSE011002R1 is a communication interface module.

Functional Features

It has communication interface functions to enable data transmission and communication with other devices. Specific communication protocols and methods may be related to specific systems and application scenarios. It supports standard USB storage devices, and through the portable program download device IC690ACC990, it can store and load VersaMax Micro 23/28 PLC application programs without a PC.

Technical Parameters

- Interface Type: Redundant interface, suitable for AF100 bus.

- Communication Protocols: Supports protocols such as Profinet, Profibus DP/V1, and multiple redundancy protocols. It is compatible with ABB's proprietary software suite and third-party control systems, enhancing interoperability and integration in complex automation networks.

- Dimensions: Length 150mm, Width 100mm, Height 50mm.

- Weight: Approximately 0.5kg.

- Operating Temperature Range: -20°C to +60°C.

- Storage Temperature Range: -40°C to +70°C.

- Input Voltage: 24VDC.

- Power Consumption: Less than 10W.

- Data Transfer Rate: Maximum 10Mbps.

- Redundancy Type: Active/active redundancy.

- Number of Channels: 16 channels.

- Connector Type: Features two ports with M12 connectors, providing flexibility to connect various devices and systems. It complies with the ISO/IEC 11801 standard to ensure compatibility with global industry standards.

Working Principle

Through relevant communication protocols and interface circuits, it encodes, decodes, and transmits data from connected devices to achieve information interaction with other devices. When the button on the portable program download device is pressed, and the name in the PLC matches and the download is complete, the relevant LED indicator lights up. If the CPU does not match or the memory stick does not have the correct file, the LED will flash, with different flashing frequencies indicating different statuses.

Application Scenarios

As an industrial control card module, it is mainly used in automated PLC/DCS equipment and suitable for industrial automation control systems. It can be applied in production process control of industries such as chemical, power, and metallurgy to achieve communication between controllers and other devices, participating in monitoring, control, and optimization of production processes.

Detailed Introduction to Common Faults and Solutions for ABB CI630K02 3BSE011002R1

1. Module Overview

CI630K02 is an Ethernet communication interface module launched by ABB, belonging to the AC 800M controller series. It is mainly used to realize data communication between controllers and Ethernet devices (such as PLCs, HMIs, third-party systems), supporting industrial Ethernet protocols such as Modbus TCP, EtherNet/IP, and Profinet. Its typical application scenarios include data interaction, monitoring, and remote control in industrial automation systems.

2. Common Fault Types and Solutions

Power Supply Faults

- Phenomena:

- Module indicator lights do not turn on (e.g., the power indicator "PWR" is off).

- The module frequently reboots or fails to initialize.

- Possible Causes:

- Loose or disconnected power supply wiring.

- Abnormal supply voltage (outside the rated range: DC 20.4V~28.8V).

- Faults in the power module or CEX bus.

- Solutions:

- Check power supply wiring: Ensure the module is properly powered via the CEX bus or an independent power supply (if available), with secure and oxidation-free terminal connections.

- Measure voltage: Use a multimeter to check if the input voltage is within the rated range and eliminate faults in the power adapter or supply circuit.

- Switch power supply paths: Try powering via redundant power supplies or replacing CEX bus slots to determine if the issue lies with the power module itself.

- Inspect surrounding modules: If multiple modules fail simultaneously, the backplane or power module may be faulty and requires step-by-step troubleshooting.

Communication Faults

- Phenomena:

- Failure to establish a connection with Ethernet devices (e.g., Modbus TCP timeout).

- Interrupted data transmission, packet loss, or high error rates.

- Abnormal communication indicator lights (e.g., "LINK/ACT" remain off, flash too fast, or show unusual colors).

- Possible Causes:

- Incorrect network parameter configuration (IP address conflicts, subnet mask, gateway errors).

- Physical connection issues (damaged network cables, loose interfaces, faulty switch ports).

- Incorrect protocol configuration (e.g., Modbus slave address, EtherNet/IP port number errors).

- Incompatible or corrupted module firmware versions.

- Signal instability due to electromagnetic interference (EMI).

- Solutions:

- Hardware Level:

- Check network cables: Use a cable tester to confirm connectivity and replace with shielded twisted-pair cables (recommended for industrial use).

- Replace switch ports or network cables to rule out switch faults.

- Ensure proper grounding of the module and keep it away from strong electromagnetic sources (e.g., motors, frequency converters).

- Software Configuration:

- Confirm that the module's IP address is compatible with the network environment (non-conflicting address and in the same subnet as the controller/host computer).

- Check communication protocol parameters in Control Builder M (e.g., Modbus TCP slave ID, register addresses).

- Enable the module's diagnostic function, view error codes (e.g., timeout, checksum errors), and adjust parameters accordingly.

- Firmware Upgrade:

- Download the latest firmware from ABB's official website and upgrade the module's firmware via Control Builder M or specialized tools.

- Protocol Compatibility Testing:

- Use packet capture tools (e.g., Wireshark) to analyze network traffic and confirm whether requests/responses comply with protocol specifications.

Module Fault Indicator Alarms

- Phenomena:

- The "ERROR" indicator on the module is constantly on or flashing (different colors represent different fault levels).

- The controller reports module communication interruptions or configuration errors.

- Possible Causes:

- Hardware damage (e.g., chip faults, bulging capacitors).

- Configuration errors (mismatch between module type and actual hardware, incorrect slot location).

- Damage to the module or backplane interface caused by hot-swapping.

- Solutions:

- Configuration Check:

- Confirm that the module type (CI630K02) in Control Builder M matches the hardware and that the slot number is correct.

- Redownload the configuration file to ensure correct module parameters (e.g., communication protocol, baud rate).

- Hardware Inspection:

- Power off and reinsert the module, clean slot dust, and ensure good contact.

- Move the module to another slot to determine if the issue is with the backplane or slot.

- If the module overheats or emits unusual odors, internal component damage may have occurred, requiring contact with ABB for repair or replacement.

- Diagnostic Log Analysis:

- View module diagnostic information via the controller or host computer to obtain specific fault codes (e.g., "HW Fault," "Configuration Error").

- Refer to the fault code table in ABB's official manual to locate the root cause.

Abnormal Data Transmission

- Phenomena:

- Erroneous, missing, or excessively delayed received data.

- Sent data not responded to by the target device.

- Possible Causes:

- Buffer overflow (data throughput exceeds the module's processing capacity).

- Incorrect protocol parameter configuration (e.g., too short timeout, insufficient retry attempts).

- Faults in the target device or communication interface.

- Solutions:

- Optimize data communication strategies:

- Reduce simultaneous data transmission volume and split large data batches into smaller packets.

- Increase communication timeout (e.g., adjust from the default 100ms to 500ms) and retry attempts.

- Verify target devices:

- Directly connect to the target device using testing tools (e.g., Modbus Poll/Slave) to confirm its normal communication functionality.

- Check the protocol compatibility of the target device (e.g., whether it supports extended function codes for Modbus TCP).

- Monitor network load:

- Use network monitoring tools to check Ethernet bandwidth utilization and avoid data delays caused by network congestion