Description

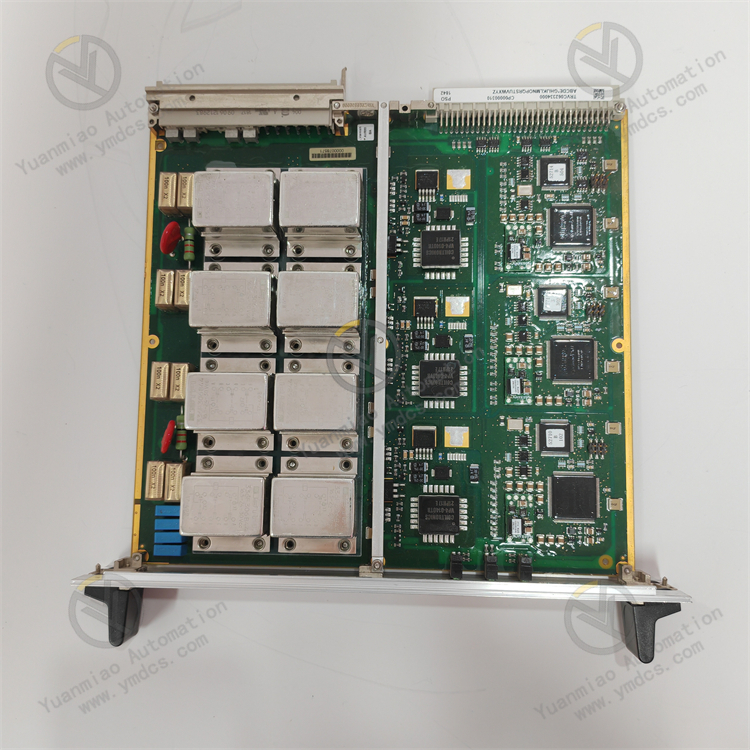

ABB 500CMP04 HE401314/0001 1MRB150051R1

I. Function and Positioning

- Belongs to the AC 500 Series Modular Controllers

ABB AC 500 is a high-performance programmable logic controller (PLC) suitable for mid-to-high-end industrial automation scenarios, such as manufacturing, process control, building automation, etc.

The "CMP" in 500CMP04 likely stands for "Communication Module" or "CPU Module." Given the series' characteristics, it is more likely a CPU Module (central processing unit). - Core Function Speculation

- Data Processing and Control: As the core of the PLC, it executes user programs, logical operations, data storage, and real-time control.

- Communication Interfaces: May integrate multiple industrial communication protocols, such as Ethernet (Ethernet/IP, PROFINET, Modbus TCP), fieldbuses (PROFIBUS DP, CANopen), etc., to connect distributed I/O, sensors, HMIs, or supervisory control systems.

- Expandability: Supports seamless integration with AC 500 series I/O modules, communication modules, power modules, etc., to build flexible control systems.

- Real-Time Performance and Reliability: Equipped with an industrial-grade real-time operating system (RTOS) for fast response and low-latency control, possibly with built-in redundancy designs (e.g., dual power supplies, dual communication links).

II. Main Features

- High-Performance Hardware Configuration

- Processor: May feature a multi-core microprocessor supporting high-speed logical operations and complex algorithms (e.g., motion control, PID regulation).

- Memory: Large-capacity program storage (e.g., Flash) and data storage (e.g., RAM) for user program expansion and data logging.

- Interfaces:

- 2× Ethernet ports (supporting real-time communication, e.g., PROFINET IRT).

- 1× PROFIBUS DP master/slave port.

- 1× RS485/RS232 port (for serial communication).

- Built-in USB port (for program download and firmware upgrades).

- Industrial-Grade Reliability Design

- Environmental Adaptability: Wide operating temperature range (e.g., -25°C ~ +60°C), resistant to vibration and shock, compliant with industrial electromagnetic compatibility (EMC) standards (e.g., EN 61000).

- Fault Diagnosis: Real-time status indication via LED lights (power, operation, communication, error), supporting self-diagnosis (e.g., hardware fault detection, program error alarms).

- Hot-Swap Support: Some models allow online module replacement to minimize downtime.

- Software and Programming

- Programming Tools: Compatible with ABB Control Builder or PLCnext Technology software, supporting IEC 61131-3 standard programming languages (Ladder Diagram LD, Function Block Diagram FBD, Structured Text ST, etc.).

- Firmware Upgrades: Supports remote upgrades via Ethernet for convenient function expansion and maintenance.

- Industrial Internet Integration: May support protocols like OPC UA and MQTT to connect with industrial internet platforms such as ABB Ability™ for remote monitoring and data analysis.

III. Typical Application Scenarios

- Manufacturing: Production line automation control, robot integration, motion control (e.g., conveyors, machine tools).

- Process Control: Distributed control systems (DCS) in chemical, power, and water treatment industries.

- Building and Energy Management: Building automation systems (BAS) and energy monitoring systems in smart buildings.

- Logistics and Warehousing: Automated storage and retrieval systems (AS/RS), conveyor system control.

IV. Technical Parameter Speculation

| Parameter Category | Parameter Value |

|---|---|

| Model | 500CMP04 HE401314/0001 1MRB150051R1 |

| Type | CPU Module (or Communication Module) |

| Power Supply | 24 V DC (±20%), power consumption approx. 15~20 W |

| Communication Interfaces | - 2× Ethernet (10/100 Mbps, PROFINET support) - 1× PROFIBUS DP - 1× RS485/RS232 |

| Protocol Support | Ethernet/IP, PROFINET, Modbus TCP, PROFIBUS DP, CANopen, etc. |

| I/O Expandability | Supports multiple distributed I/O modules (e.g., DI/DO, AI/AO) |

| Operating Temperature | -25°C ~ +60°C (fanless) |

| Protection Level | IP20 (suitable for installation in control cabinets) |

V. Operation and Maintenance Recommendations

- Installation and Wiring

- Install in a well-ventilated control cabinet, keeping distance from heat-generating components.

- Use shielded cables for communication wiring and ensure reliable grounding to avoid electromagnetic interference.

- Ensure correct power polarity to prevent overload or voltage fluctuations.

- Configuration and Debugging

- Configure IP addresses and communication protocol parameters (e.g., slave address, baud rate) via ABB programming software.

- Test communication link connectivity with diagnostic tools and verify normal I/O signal input/output.

- Maintenance and Fault Troubleshooting

- Status Monitoring: Judge module status via LED lights (e.g., check power supply if the power light is off; inspect wiring or protocol settings if the communication light blinks abnormally).

- Common Faults and Solutions:

- Communication Interruption: Check cable connections and protocol compatibility; restart the module or redownload the program.

- Abnormal Program Operation: Inspect logical errors or memory overflow; trace variables with software debugging tools.

- Hardware Faults: Contact ABB technical support to replace spare parts if the module overheats or is damaged.

General Fault Troubleshooting Directions and Solutions (for Reference)

I. Communication-Related Faults

- Communication Interruption or Data Anomalies

- Fault Phenomenon: The module cannot communicate with the CPU, other modules, or supervisory systems (e.g., HMI, SCADA), or data transmission is erroneous/delayed.

- Possible Causes:

- Loose, damaged, or poorly grounded communication cables.

- Incorrect communication parameter settings (e.g., IP address conflicts, baud rate mismatches, wrong slave addresses).

- Protocol compatibility issues (e.g., incorrect protocol or gateway function activation).

- Electromagnetic interference (e.g., parallel routing of high-power and communication cables).

- Solutions:

- Check communication cable connections, use shielded cables with reliable grounding, and replace cables if necessary.

- Reconfigure communication parameters (e.g., via ABB Control Builder) to match the communication partner.

- Confirm the module’s supported protocols (e.g., PROFIBUS, PROFINET, Ethernet/IP) and enable the correct protocol stack.

- Separate communication and high-power cables or add anti-interference measures (e.g., filters).

- Module Unrecognized (Offline)

- Fault Phenomenon: The module cannot be detected in system configuration, or status indicators show abnormalities (e.g., communication light off).

- Possible Causes:

- Incorrect module installation or poor contact (e.g., loose rail clips).

- Backplane bus faults (e.g., poor contact or damage in the AC 500 rack backplane).

- Incompatible module firmware version with the CPU.

Solutions:

- Reinsert the module to ensure tight backplane bus connection.

- Inspect backplane bus interfaces for oxidation/dust, clean and retry; replace the rack if the backplane is damaged.

- Upgrade module firmware to a version compatible with the CPU via ABB official tools (e.g., Bootloader).

II. Power Supply Faults

- No Power (Power Light Off)

- Fault Phenomenon: The module’s power indicator (e.g., PWR light) is off, and it cannot start.

- Possible Causes:

- External power supply not connected or voltage anomalies (e.g., 24V DC power failure).

- Loose, shorted, or reverse-polarity power terminals.

- Internal power circuit damage in the module.

- Solutions:

- Measure input voltage with a multimeter to ensure it is within the rated range (e.g., 24V DC ±20%), and check power switches and fuses.

- Inspect power wiring for tight connections, correct polarity, and short-circuit hazards.

- Contact ABB technical support or replace the module if internal power faults are confirmed.

- Flashing Power Indicator (Abnormal Alarm)

- Fault Phenomenon: The power light flashes, possibly with other fault lights (e.g., ERROR light) on.

- Possible Causes:

- Excessive power voltage fluctuations or ripple.

- Module overload (e.g., external device power consumption exceeds the rated load).

- Internal circuit anomalies (e.g., aged capacitors, chip faults).

- Solutions:

- Check power stability and use a voltage regulator or add filter capacitors.

- Reduce external loads to ensure total power consumption is within the rated range.

- Return for repair or replace the module if internal hardware faults are confirmed.

III. Hardware and Module Status Faults

- Module Overheating

- Fault Phenomenon: Excessive module surface temperature, possibly triggering overheat protection and causing functional anomalies or shutdowns.

- Possible Causes:

- Poor ventilation in the installation environment (e.g., no cooling fan in the control cabinet).

- Ambient temperature exceeds the module’s rated range (e.g., >+60°C).

- Long-term full-load operation with blocked heat dissipation channels.

- Solutions:

- Ensure the module is installed in a well-ventilated control cabinet, keeping distance from heat-generating components (e.g., power modules, inverters).

- Clean dust from module cooling vents and install cooling fans or air conditioners to lower ambient temperature if necessary.

- Optimize system configuration to avoid long-term high-load operation.

- Abnormal Indicator Lights (e.g., ERROR Light On)

- Fault Phenomenon: The module’s ERROR, FAULT, or other status lights are constantly on or flashing.

- Possible Causes:

- Hardware faults (e.g., memory damage, chip faults).

- Configuration errors (e.g., module type mismatch with actual setup).

- External device faults causing module alarms (e.g., slave devices offline).

- Solutions:

- Read module diagnostic information (e.g., error codes) via ABB programming software to locate specific fault points.

- Check system configuration to ensure module model and version match the setup.

- Replace the module if hardware is damaged; repair slave devices first if the issue is external.

IV. Software and Configuration Faults

- Program Download Failure or Abnormal Operation

- Fault Phenomenon: Inability to download programs to the module, or logical errors/crashes during program execution.

- Possible Causes:

- Incompatible programming software version with module firmware.

- Syntax errors or logical conflicts in the program (e.g., double coil outputs).

- Insufficient module memory (e.g., oversized programs or data cache overflow).

- Solutions:

- Update programming software to the latest version or downgrade module firmware to a compatible version.

- Check program logic and use software debugging tools (e.g., online monitoring) to troubleshoot errors.

- Optimize program structure to free up unnecessary memory (e.g., delete redundant variables, compress data).

- Data Loss or Parameter Reset

- Fault Phenomenon: Configuration parameters are lost after module power-off, or data is unexpectedly cleared during operation.

- Possible Causes:

- Depleted internal battery (if module supports battery backup).

- Firmware defects causing storage anomalies.

- Solutions:

- Replace the module’s internal battery (if applicable) and redownload configuration parameters.

- Contact ABB technical support for firmware patches to fix storage vulnerabilities.