Description

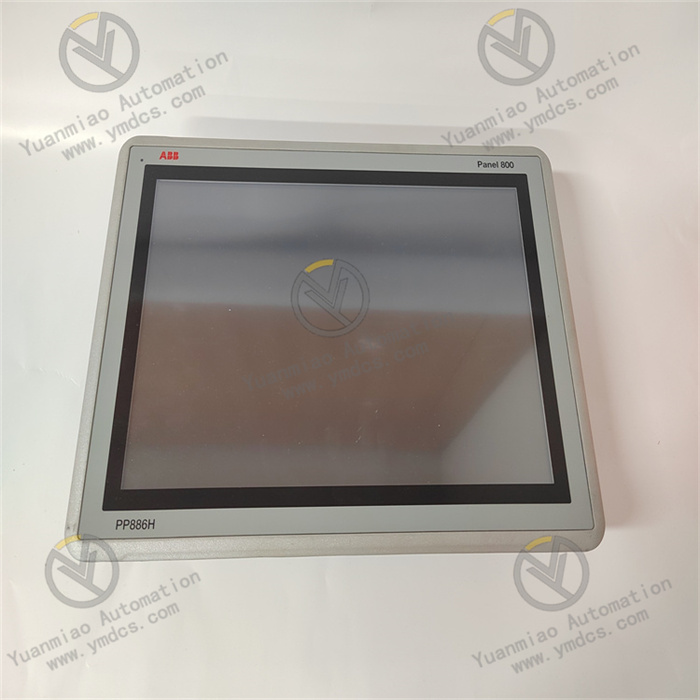

ABB PP886H 3BSE069297R1

ABB PP886H 3BSE069297R1 is a 15.4-inch touchscreen belonging to ABB's Panel 800 series. As an easy-to-use human-machine interface (HMI), it is designed for monitoring and controlling automation systems. With its vibrant TFT/LED display and touch input, it provides operators with an intuitive interactive interface to monitor, operate, and control devices in various scenarios such as industrial automation processes, building automation systems, and power systems.

Functional Features

1. High-Performance Hardware Design

Industrial-Grade Durability

- Wide Temperature Range: Operates at -10°C to +60°C, suitable for harsh industrial environments (e.g., air-conditioned control cabinets).

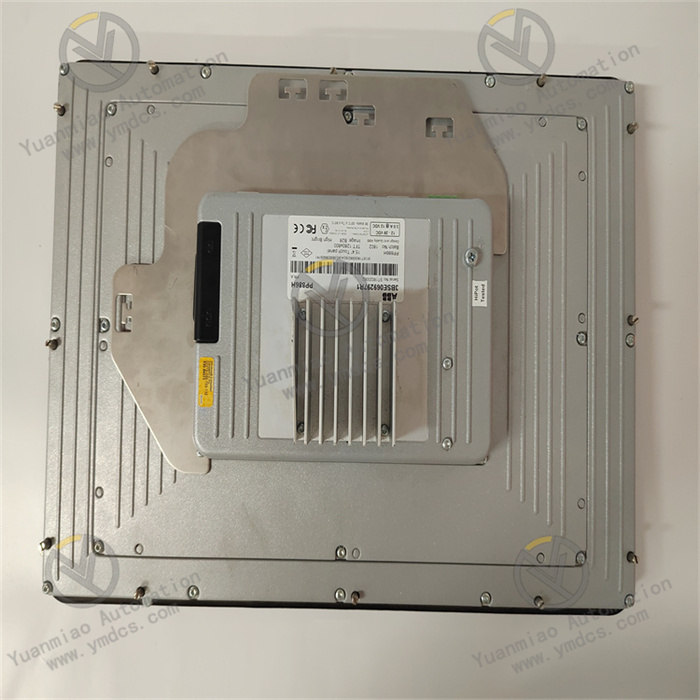

- Protection Ratings: Front panel IP65 (dust and water-resistant, suitable for washdown scenarios); rear panel IP20 (protected against solid objects).

- Vibration/Shock Resistance: Complies with IEC 60068-2 standards, adapting to vibrating environments (e.g., production lines, construction machinery).

High-Resolution Touch Display

- 15.4-inch Wide Screen: 1280×800 pixels (16:10 aspect ratio), supporting clear visualization of complex flowcharts, trend graphs, and alarm information.

- LED Backlight: 450cd/m² brightness for good visibility in strong light, with optional automatic brightness adjustment.

- Resistive Touchscreen: Supports gloved operation, single-touch response <10ms, and a service life of >50 million clicks.

Powerful Data Processing

- ARM9 1GHz Processor: Enables fast interface response and multitasking (e.g., simultaneous screen updates, data logging, and communication).

- 1GB RAM + 2GB SSD: Stores user programs, historical data, and recipes, with power-off data protection (configurable).

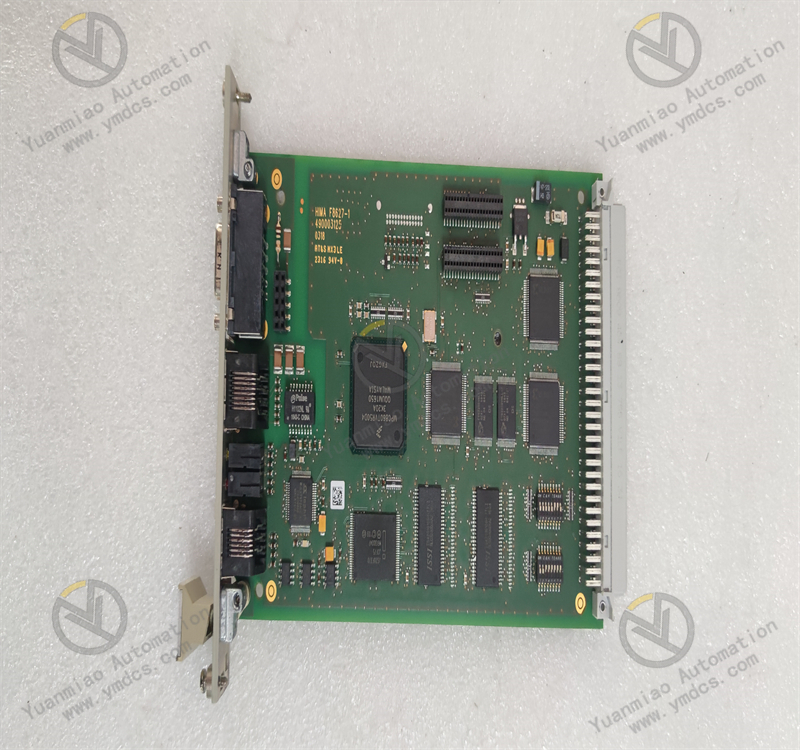

2. Rich Communication Capabilities

Multi-Protocol Compatibility

- Built-in support for mainstream industrial protocols such as Modbus RTU/TCP, Profibus DP, Ethernet/IP, and DeviceNet, enabling connection to ABB PLCs (e.g., AC 800M), third-party controllers, or smart devices.

- OPC UA Server: Seamlessly integrates with SCADA systems, MES, or cloud platforms for remote monitoring.

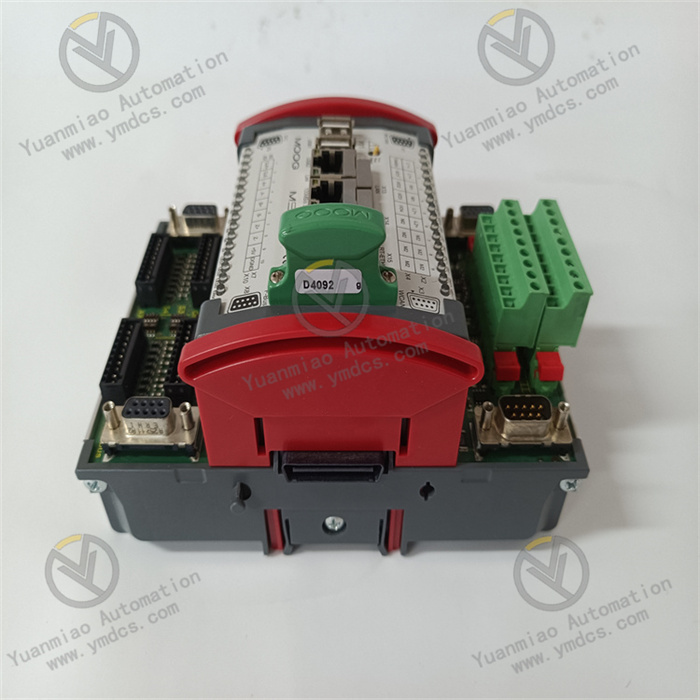

Multi-Interface Design

- 2× Ethernet Ports: Can be configured for redundant networks or simultaneous connection to different devices (e.g., PLCs and host computers).

- 2× USB 2.0: Supports external printers, USB drives (for program backup and data export), or keyboards/mice.

- 3× Serial Ports (RS-232/422/485): Flexibly adapts to different communication devices (e.g., instruments, variable frequency drives).

3. Intelligent Software Functions

Intuitive Graphical Programming

- Compatible with Panel Builder 800 software, supporting drag-and-drop interface design and offering a rich library of pre-defined graphics (e.g., valves, motors, instruments).

- Dynamic Screens: Supports trend curves, alarm lists, and 3D animation effects to reflect production status in real time.

Flexible Data Handling

- Recipe Management: Stores and recalls production parameters (e.g., temperature, pressure), supporting batch production switching.

- Historical Data Logging: Built-in data logging function supports CSV export and can be accessed via USB or network.

- Alarm Management: Supports hierarchical alarms (e.g., emergency, warning, notice), with configurable audible-visual alarms and SMS notifications (requires external modules).

Security and Permission Control

- User Hierarchy Management: Assigns different operation permissions (e.g., operator, engineer, administrator) via passwords or RFID cards.

- Audit Trail: Records all operations and system events to meet compliance requirements (e.g., FDA 21 CFR Part 11).

4. Convenient Maintenance and Expansion

Plug-and-Play Design

- Hot-Swappable Interfaces: Supports live replacement of USB devices or network cables to reduce downtime.

- Remote Maintenance: Enables remote access via Ethernet or VPN for program updates and fault diagnosis.

Redundancy and Backup

- Power Redundancy: Supports dual DC 24V inputs to enhance system reliability.

- Data Backup: Automatically backs up user programs and configuration files to external storage.

Open Ecosystem

- Third-Party Expansion: Supports integration with third-party software (e.g., data analysis tools) via OPC UA, REST API, etc.

- Modular Design: Can expand I/O modules (e.g., digital inputs/outputs) for local control functions.

Technical Parameters

- Display Specifications: 15.4-inch touchscreen, 1280×800 pixels (16:10), 450cd/m² brightness, TFT/LED display with high-resolution graphics capability.

- Processor and Memory: ARM9 (1GHz) processor, 1GB main memory, 2GB SSD external storage (1.5GB available for application storage).

- Interface Types: 2× Ethernet ports (10/100Base-T, RJ45), 2× USB 2.0 ports (500mA), 1× RS-232, 1× RS-422/485, and 1× RS-485 (when COM2 is RS-485).

- Power Requirements: DC 24V (18–32V DC range), 31.2W power consumption.

- Operating Environment: -10°C to +60°C, 5%–85% relative humidity (non-condensing); front panel IP65, NEMA 4X/12, UL Type 4X/12; rear panel IP20.

- Physical Dimensions: 410mm×286mm×61mm (W×H×D), approximately 3.85kg in weight.

Working Principle

The PP886H communicates with controllers, PLCs, and other devices in the automation system to receive data, which is displayed on the touchscreen as graphics, text, etc., to show the system's operating status and parameter information. Operators can modify parameters, send control commands, etc., via touch operations. These commands are transmitted to corresponding devices through communication interfaces to achieve system control.

Application Scenarios

- Industrial Automation: Creates intuitive control interfaces for monitoring and operating production processes in manufacturing, chemical, and petrochemical industries.

- Building Automation: Controls building systems such as air conditioning, lighting, and security.

- Power Systems: Monitors and controls power plants, substations, and grid equipment in the power industry.

- Transportation Systems: Provides intuitive interfaces for traffic signal control and intelligent transportation systems.

- Medical Equipment: Serves as an operational interface for medical devices (e.g., diagnostic and surgical equipment).

- Data Center Management: Monitors and manages data center equipment, offering visual control of servers and network devices.

- Refrigeration and Air Conditioning Systems: Controls and monitors air conditioning equipment operations.

Operation and Maintenance Recommendations

- Installation Notes: Install according to device requirements, ensuring the environment's temperature and humidity meet operational needs. Ensure good heat dissipation and accessible installation locations for easy operation and maintenance.

- Wiring Standards: Use shielded cables for communication lines to reduce electromagnetic interference and ensure stable communication. Route cables correctly per interface requirements and secure connections to avoid loose contacts causing faults.

- Parameter Configuration: Configure parameters (e.g., communication settings, display parameters, control logic) via software like Panel Builder 800, aligning with actual application scenarios for accurate setup and normal device communication.

- Maintenance and Fault Troubleshooting: Regularly inspect device status (display, touch sensitivity, communication stability). For faults, refer to diagnostic information/error codes: no display (check power/connections), unresponsive touch (check screen/drivers), communication interruptions (check parameters/network links). Keep the device clean to prevent dust/oil from affecting performance and lifespan.