Description

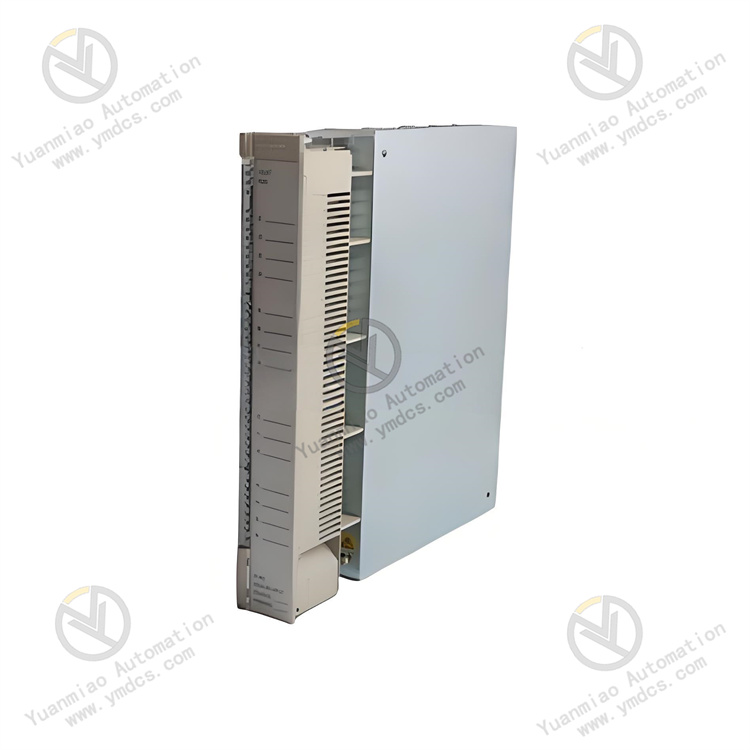

TRICONEX 4352AN

I. Overview

II. Technical Parameters

Processing capability: Equipped with a high-performance processor with fast computing speed, it can quickly process complex control logic and a large amount of real-time data. It supports multiple programming languages such as ladder diagrams and function block diagrams, facilitating engineers in program development and debugging to meet the control needs of different industrial scenarios.

Communication capability: Supports multiple industrial communication protocols such as Modbus RTU and EtherNet/IP, enabling efficient data interaction with upper computers, HMIs (Human-Machine Interfaces), and other intelligent devices. The communication interface adopts an isolation design with strong anti-interference ability, ensuring stable communication in complex industrial electromagnetic environments.

Safety certification: Certified by SIL3 (Safety Integrity Level 3) and compliant with international safety standards such as IEC 61508. It reaches the industry-leading level in safety performance and can meet the strict requirements for safety control in high-risk industrial scenarios.

III. Functional Features

Triple Modular Redundancy (TMR) technology: Inherits the core redundancy technology of the TRICONEX series, consisting of three independent processing channels. Each channel runs the same program synchronously and performs data comparison. Through the hardware voting mechanism, it ensures that the system can still work normally when a single channel fails, greatly improving the reliability and safety of the module and avoiding safety accidents caused by single-point faults.

Online diagnosis and fault alarm: Equipped with a powerful self-diagnosis function, it can real-time monitor the internal hardware status of the module, program operation, and the integrity of input/output signals. When a fault is detected, it can immediately send an alarm signal, upload fault information to the monitoring system through the communication interface, and display the fault type through indicator lights on the module panel, facilitating maintenance personnel to quickly locate and eliminate faults.

Compatibility and expandability: It has good compatibility with other modules and systems of the TRICONEX series and can be easily integrated into existing TRICONEX safety instrumented systems. At the same time, it supports increasing the number of input/output points and communication interfaces through expansion modules to meet the growing control needs of industrial sites and provide convenience for system upgrading and expansion.

IV. Common Faults and Solutions

Causes of failure: Poor contact or disconnection of the communication line; incorrect setting of communication protocol parameters, such as mismatched baud rate or address; damage to the communication interface.

Solutions: Check the connection of the communication line, re-plug the connector or replace the damaged cable; check and reconfigure the communication protocol parameters to ensure consistency with the communicating device; if the interface is damaged, replace the communication interface module or contact professionals for repair.

No response to input signals

Causes of failure: Short circuit or open circuit of the input line; failure of external devices such as sensors; damage to the input channel.

Solutions: Use a multimeter to detect the on-off status of the input line and repair the broken or short-circuited points; check whether the external devices are working normally and replace the faulty ones; determine if the input channel is damaged by the replacement method, and replace the module if it is damaged.

Causes of failure: Short circuit of the output line leading to protection of the output channel; failure of the actuator; damage to the output channel.

Solutions: Inspect the output line to eliminate the short-circuit fault; check the working status of actuators (such as relays and solenoid valves) and replace the faulty ones; if the output channel is damaged, replace the module or repair the corresponding parts.

Module alarm indicator stays on

Causes of failure: Internal hardware faults of the module, such as faults in the power module or processor; program operation errors; excessive temperature or abnormal power supply.

Solutions: Check whether the supply voltage of the module is normal, ensuring it is within the 24V DC range; check the operating environment temperature of the module, and improve ventilation and heat dissipation conditions if the temperature is too high; read the fault code through programming software to locate the cause of the fault. If it is a hardware fault, contact the manufacturer for repair or replace the module.