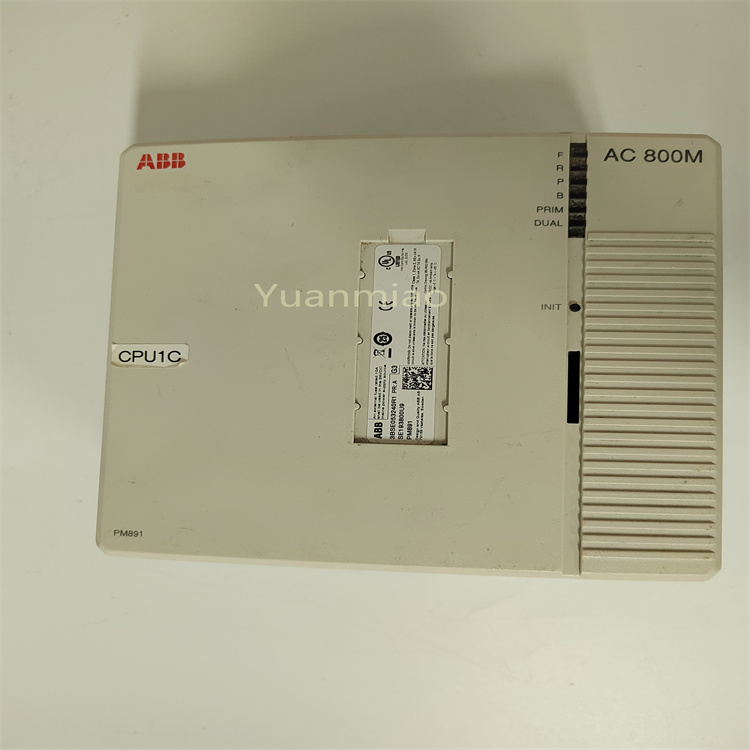

Description

ABB 500CPU03 1HDF700003R5122

The ABB 500CPU03 (Model: 1HDF700003R5122) is the core processor module of the AC500 series PLC (Programmable Logic Controller). As a mid-range high-performance controller, it serves as the core controller for the AC500 series. With its high-performance processing, flexible expansion, and reliable industrial-grade design, it is suitable for core control tasks in small to medium-sized automation systems. Its rich communication interfaces and programming compatibility make it an ideal choice for intelligent manufacturing, process control, and energy management.

Functional Features

High-Performance Processing

- Equipped with a 32-bit RISC processor running at up to 200 MHz, supporting fast execution of programming languages such as Ladder Diagram (LD), Structured Text (ST), and Function Block Diagram (FBD).

- Built-in large-capacity memory: Up to 512 KB for program storage (Flash) and 256 KB for data storage (RAM), capable of handling large-scale control logic and data.

Rich Communication Interfaces

- Standard configuration includes 2 serial communication interfaces (RS232/RS485, supporting Modbus RTU protocol) for connecting sensors, instruments, or third-party devices.

- Integrated Ethernet interface (10/100 Mbps) supporting industrial Ethernet protocols such as PROFINET, EtherNet/IP, and Modbus TCP, enabling high-speed data interaction with supervisory control and data acquisition (SCADA) systems, cloud platforms, or other controllers.

- Supports fieldbus expansion: Connects to distributed I/O systems (e.g., ABB AC500-ECO series) via optional modules (e.g., PROFIBUS DP master/slave stations).

Flexible Expansion Capability

- Supports local expansion modules: Directly connects to analog/digital I/O modules, counter modules, temperature modules, etc., via a bus interface, with a maximum expansion of 16 modules.

- Compatible with distributed I/O systems: Extends system scale by connecting to remote I/O stations via Ethernet or fieldbus.

High-Reliability Design

- Industrial-grade hardware standards: Operating temperature range of -25°C to +60°C, humidity of 5% to 95% non-condensing, with vibration/shock resistance complying with IEC 61131-2 standards.

- Built-in Real-Time Clock (RTC) and non-volatile memory (no battery required to maintain data), ensuring programs and data are retained during power outages.

- Supports redundant power input (optional) to enhance system power supply reliability.

Convenient Programming and Debugging

- Uses ABB Control Builder PM or Codesys programming software, supporting offline programming, online debugging, and firmware upgrades.

- Features diagnostic functions: Real-time operating status display via LED indicators (e.g., RUN, ERROR, COMM), supporting fault code reading and log recording.

Technical Parameters

| Parameter Category | Detailed Parameters |

|---|---|

| Processor | 32-bit RISC processor, 200 MHz clock speed |

| Memory Configuration | - Program storage: 512 KB (Flash) - Data storage: 256 KB (RAM) |

| Communication Interfaces | - 1×Ethernet (10/100 Mbps, supports PROFINET, EtherNet/IP) - 2×RS232/RS485 |

| Local Expansion Capacity | Supports up to 16 local I/O modules (via X2 bus interface) |

| Distributed I/O Support | Connects to AC500-ECO distributed I/O systems (via Ethernet or PROFIBUS DP) |

| Operating Power Supply | - DC: 24 VDC (±20%) - AC: Optional 100-240 VAC (requires adapter) |

| Power Consumption | Typical ≤10 W |

| Physical Dimensions | Width × Height × Depth: 36 mm × 125 mm × 110 mm (compact design for small spaces) |

| Installation Method | Standard DIN rail mounting (35 mm) |

| Protection Class | IP20 (requires installation in a control cabinet) |

Comparison with Series Products

| Model | 500CPU02 | 500CPU03 | 500CPU04 |

|---|---|---|---|

| Processor Speed | 100 MHz | 200 MHz | 400 MHz |

| Program Storage | 256 KB | 512 KB | 1 MB |

| Ethernet Interface | 1×10/100 Mbps | 1×10/100 Mbps | 2×10/100 Mbps (redundant) |

| Max Local Expansion | 8 modules | 16 modules | 32 modules |

| Application Scenario | Small standalone control | Medium distributed systems | Large complex control systems |

Application Fields

- Manufacturing: Production line control, robot coordination, assembly inspection, etc.

- Process Control: Process automation in chemical, food & beverage, and pharmaceutical industries.

- Energy and Power: Substation monitoring, renewable energy system management.

- Building Automation: Smart building control, heating, ventilation, and air conditioning (HVAC) systems.