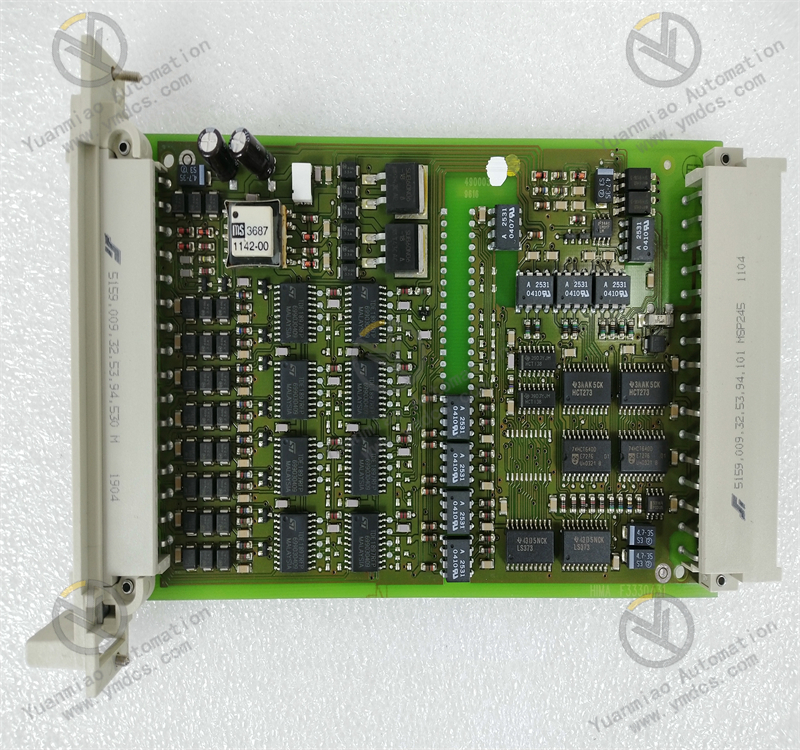

Description

ABB CI810V1 3BSE008584R1

Technical Parameters

Input Characteristics: Usually, it supports various types of input signals. For example, for analog input, it may accept standard voltage signals (such as 0 - 10V) or current signals (such as 4 - 20mA) to adapt to the output signal types of different sensors. It can accurately collect physical quantity information on site, such as signals from sensors of temperature, pressure, flow rate, etc. Output Characteristics: It has analog output channels and can output standard analog signals for controlling actuators, such as control valves, frequency converters, etc. The output signals have high precision and stability, and can accurately transmit control signals to the actuating devices, enabling precise control of the industrial process. Number of Channels: It has multiple input and output channels. The specific number depends on the product model and configuration. Generally, there are multiple channels available to connect multiple field devices, enabling simultaneous monitoring and control of multiple parameters to meet the requirements of complex industrial systems. Communication Interface: It supports common industrial communication protocols, such as Profibus, Modbus, etc., making it convenient to communicate with the host computer control system or other devices, and realizing the transmission and exchange of data. The communication rate can be configured according to actual needs to ensure efficient and stable data communication. Isolation Performance: To ensure the safety and stability of the system, it has good electrical isolation function. Technologies such as photoelectric isolation or electromagnetic isolation are used between the input and output channels and the power supply to effectively prevent external interference signals from entering the system. At the same time, it can avoid mutual interference among various parts inside the system. The isolation voltage is generally high, which can reach several thousand volts.

Functional Features High-precision Measurement and Control: It adopts advanced A/D and D/A conversion technologies, enabling high-precision analog measurement and control. It can accurately sample and convert the input signals to ensure that the collected data accurately reflects the actual situation on site. At the same time, it can accurately output control signals to achieve fine adjustment of the industrial process. Flexible Configuration Method: Through dedicated configuration software, users can flexibly configure various parameters of the module according to actual application requirements, such as the types, ranges, filtering parameters, alarm thresholds, etc. of the input and output channels. It can adapt to different industrial field environments and control requirements, realizing personalized system integration. Reliability Design: The product uses high-quality electronic components and advanced manufacturing processes. After strict quality inspection and environmental testing, it has the abilities of anti-interference, anti-vibration, anti-shock, etc. It can operate stably for a long time in harsh industrial environments. At the same time, it has a self-diagnosis function, which can monitor the working status of the module in real time. When a fault occurs, it can send out alarm signals in a timely manner and provide detailed fault information, facilitating maintenance personnel to quickly locate and troubleshoot the fault.

Common Faults and Solutions Abnormal Input Signals Phenomenon: The collected input signals do not match the actual values, or the signals fluctuate greatly. Cause: It may be caused by sensor failures, poor wiring, damage to the module's input channels, or external interference. Solution: First, check whether the sensor is working properly. You can judge by replacing the sensor or comparing it with other normal sensors. Check whether the wiring is firm and whether there are loose, open circuit or short circuit phenomena. If the wiring and the sensor are normal, try to calibrate the input channel of the module or check whether the configuration parameters of the channel are correct. If external interference is suspected, check whether there are strong electromagnetic interference sources around and take corresponding anti-interference measures, such as using shielded cables, adding filters, etc. Output Signal Faults Phenomenon: It cannot output correct control signals, or the output signals are unstable. Cause: It may be caused by damage to the module's output channels, load failures, incorrect software configuration, or power supply problems. Solution: Check whether the load device is working properly and whether there are overload, short circuit, etc. Check whether the configuration parameters of the module's output channels are correct and whether they match the load device. If the configuration is correct, try to diagnose and test the output channel to see if there are hardware failures. If a power supply problem is suspected, check whether the power supply of the module is stable and whether the voltage is within the specified range. Communication Faults Phenomenon: The module cannot communicate normally with the host computer or other devices, resulting in the inability to transmit data or issue control commands. Cause: It may be caused by damage to the communication interface, incorrect communication protocol settings, network connection problems, or electromagnetic interference. Solution: Check whether the connection of the communication interface is normal and whether there are loose or damaged parts. Confirm whether the communication protocol settings are consistent with those of the opposite device, including parameters such as baud rate, data bits, stop bits, and parity bits. Check whether the network connection is normal. If necessary, use network detection tools to check the network status. If electromagnetic interference is suspected, check whether there are strong interference sources around and take corresponding anti-interference measures, such as using shielded cables, adding filters, etc.

Application Areas

Industrial Automation Production Lines: It is widely used in the automation production lines of various manufacturing industries, such as the automotive manufacturing, mechanical processing, and electronic device production industries. It is used to monitor and control various devices on the production line, realizing the automation and intelligence of the production process, and improving production efficiency and product quality.

Process Control Systems: In process industries such as chemical, petroleum, natural gas, and pharmaceutical industries, it is used for precise control and monitoring of key parameters in the production process, such as temperature, pressure, flow rate, liquid level, etc., ensuring the stability and safety of the production process and achieving the goals of optimized production and energy conservation and emission reduction.

Power Systems: It can be applied to power facilities such as power plants and substations, and is used for the automation control and monitoring of the power system, such as the status monitoring and protection of devices such as generators, transformers, and transmission lines, as well as the dispatching and control of the power system to ensure the reliable operation of the power system.

Smart Buildings: In the field of smart buildings, it is used in building automation systems, such as controlling the lighting system, air conditioning system, elevator system, etc., realizing the energy management and automated operation of building equipment, improving the comfort and energy efficiency of the building, and providing users with a more convenient and efficient building environment.