Description

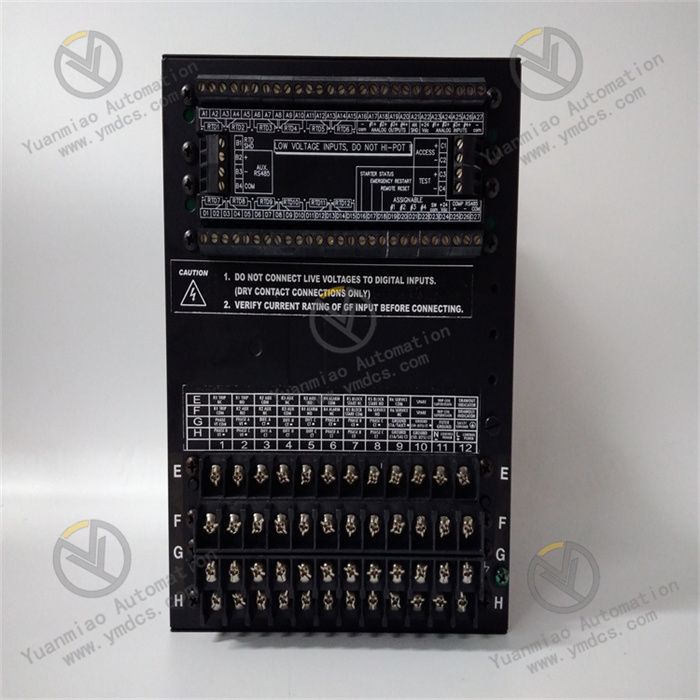

GE SR469-P1-HI-A20-E

I. Product Overview

II. Functional Features

Accurate measurement and monitoring: It can accurately measure key operating parameters of the motor, such as current, voltage, power, and power factor, with high measurement accuracy, providing operators with accurate information on the motor's operating status. Through continuous monitoring of these parameters, abnormal changes in motor operation can be found in a timely manner, providing data support for preventive maintenance and reducing the occurrence of sudden failures.

Flexible configuration and adaptability: It supports multiple motor types, such as asynchronous motors and synchronous motors, and can meet the protection needs of different types of motors. It provides a wealth of parameter setting options, allowing users to flexibly adjust parameters such as protection thresholds and action time according to the specific parameters and operating conditions of the motor, making the protection function more suitable for actual application scenarios. In addition, it also supports multiple communication protocols, facilitating integration with industrial control systems to achieve remote monitoring and control.

Convenient diagnosis and maintenance: It is equipped with an intuitive human-machine interface, which can display the motor's operating parameters, fault information, etc., making it convenient for operators to view and understand the motor status. It has a complete fault recording function, which can store information such as the type of fault occurring in the motor, the fault time, and the parameters at the time of the fault, providing a basis for fault 排查 and analysis. At the same time, it supports online testing and diagnosis functions, facilitating maintenance personnel to inspect and maintain the relay itself and the motor system, improving maintenance efficiency.

III. Technical Parameters

Power supply voltage: Usually supports common industrial power supply voltages such as AC 110V and 220V, which can be selected according to actual needs to ensure compatibility with the on-site power supply system.

Power consumption: In normal working conditions, the power consumption is low, generally within 10W, reducing energy consumption.

Current measurement range: It can measure a wide range of currents, such as 0.1A - 600A, and can adapt to motors of different power sizes.

Voltage measurement range: Supports AC 0 - 600V voltage measurement, meeting the voltage monitoring needs of most industrial motors.

Protection parameters:

Overcurrent protection action value: It can be set within the range of 1.2 - 10 times the rated current of the motor, and the action time can be adjusted as needed, usually 0.01s - 10s.

Overload protection: Follows the inverse time characteristic, automatically adjusting the action time according to the size of the overload current. The larger the overload multiple, the shorter the action time.

Locked-rotor protection action current: Generally set to 2 - 8 times the rated current of the motor, and the action time can be adjusted within the range of 0.1s - 5s.

Overcurrent protection action value: It can be set within the range of 1.2 - 10 times the rated current of the motor, and the action time can be adjusted as needed, usually 0.01s - 10s.

Overload protection: Follows the inverse time characteristic, automatically adjusting the action time according to the size of the overload current. The larger the overload multiple, the shorter the action time.

Locked-rotor protection action current: Generally set to 2 - 8 times the rated current of the motor, and the action time can be adjusted within the range of 0.1s - 5s.

Communication parameters:

Communication interface: It may be equipped with RS-485 and other communication interfaces, supporting Modbus and other common industrial communication protocols, facilitating data interaction with PLC, SCADA and other systems.

Baud rate: Supports multiple baud rate settings, such as 9600bps, 19200bps, etc., to ensure the stability and flexibility of communication.

Communication interface: It may be equipped with RS-485 and other communication interfaces, supporting Modbus and other common industrial communication protocols, facilitating data interaction with PLC, SCADA and other systems.

Baud rate: Supports multiple baud rate settings, such as 9600bps, 19200bps, etc., to ensure the stability and flexibility of communication.

Environmental parameters:

Operating temperature: The operating temperature range is usually -20°C - +70°C, and it can work stably in relatively harsh industrial environments.

Relative humidity: It can operate in an environment with 5% - 95% (non-condensing) relative humidity, and has good moisture resistance.

Operating temperature: The operating temperature range is usually -20°C - +70°C, and it can work stably in relatively harsh industrial environments.

Relative humidity: It can operate in an environment with 5% - 95% (non-condensing) relative humidity, and has good moisture resistance.

IV. Working Principle

Signal processing and analysis: The analog-to-digital converter inside the relay converts the collected analog signals into digital signals, and the microprocessor processes and analyzes these digital signals. The real-time measured current, voltage and other parameters are compared with the preset protection thresholds to determine whether the motor is in normal operation.

Protection action execution: When it is detected that the motor has abnormal conditions such as overcurrent, overload, or locked-rotor, the microprocessor issues instructions according to the preset protection logic, drives the output contacts of the relay to act, cuts off the power supply of the motor, and prevents the motor from being damaged. At the same time, fault information is displayed on the human-machine interface, and fault data is recorded.

Communication and feedback: The motor's operating status parameters, fault information, etc. are transmitted to the superior control system through the communication interface to realize remote monitoring. Operators can set parameters and remotely control the relay through the control system, and the relay can also feed back its own working status to the control system to ensure the coordinated operation of the entire motor control system.