Description

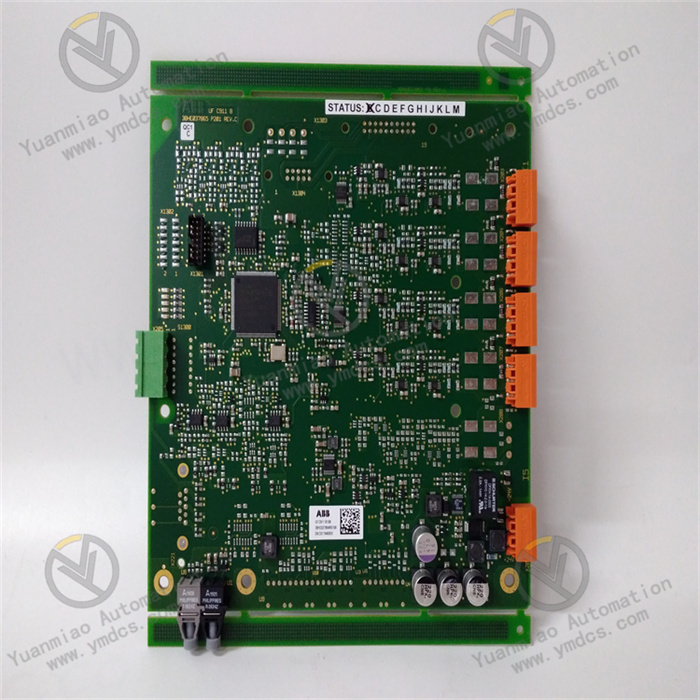

ABB PP846A 3BSE042238R2

The ABB PP846A 3BSE042238R2 is a control display panel primarily used for human-machine interaction in industrial automation control systems. It achieves two-way data interaction between humans and control systems through hardware interfaces, defines interaction logic via software configuration, and ensures reliability and real-time performance through industrial-grade design. Its core value lies in simplifying the monitoring and control processes of complex industrial systems for operators, while serving as a bridge between underlying devices and upper-level management systems (such as MES and SCADA) to enhance the integration and operability of automation systems.

Features and Functions

- Human-Machine Interface: As a human-machine interaction device, it typically features user interfaces such as touchscreens or buttons, facilitating the operation and monitoring of control systems by operators.

- Display Function: Equipped with a high-resolution display, it clearly shows real-time status, parameters, alarm information, etc., of the control system, providing intuitive information display for operators.

- Control Function: Supports control operations such as setting control parameters, starting/stopping devices, and switching working modes, enabling operators to directly control industrial devices or production processes through the panel.

- Communication Interfaces: Features multiple communication interfaces (e.g., Ethernet, serial ports) for data exchange and communication with control systems or other devices, enabling integration and collaborative operation with other equipment.

- Alarm Function: Timely alerts are issued when abnormal conditions occur in the control system, notifying operators to take action. This helps quickly identify and resolve issues, ensuring stable system operation.

- Reliability and Stability: Designed for industrial environments, it adapts to harsh conditions such as high temperatures, dust, and electromagnetic interference, offering high reliability and stability for long-term stable operation.

- Modular Design: The modular design facilitates installation, maintenance, and replacement. Users can select and configure corresponding modules according to actual needs, enhancing equipment flexibility and scalability.

- Security: May include security features such as password protection and user permission management to safeguard the security and stability of control systems and prevent unauthorized operations.

Technical Parameters

- Power Supply: Supports DC 24V input.

- Dimensions: Approximately 300×150×290mm, weighing about 4.6kg.

- Touchscreen Size: 10.4-inch touchscreen.

- Sampling Rate: Supports sampling rates from 5KSa/s to 200MSa/s.

- Vertical Resolution: 8 bits.

- Vertical Sensitivity: 2mV to 5V/div for all models when using calibrated fine-tuning.

- DC Vertical Accuracy: ±3% for all models.

Working Principle

As a control display panel in the industrial automation field, the working principle of the ABB PP846A 3BSE042238R2 is centered around human-machine interaction, data communication, real-time control, and system integration, aiming to provide operators with convenient monitoring and control interfaces while ensuring efficient coordination with underlying control systems. The working principle is as follows:

1. Hardware Architecture and Signal Interaction

- Signal Processing at Input/Output Interfaces:

- User Input: Receives operator commands (e.g., parameter setting, device start/stop, mode switching) through the panel's touchscreen, buttons, or knobs. These physical signals are parsed into digital signals by an embedded controller.

- Data Acquisition: Real-time data (e.g., temperature, pressure, device status) is acquired from underlying control systems (e.g., PLC, DCS controllers) or field devices (e.g., sensors, variable frequency drives) via built-in communication interfaces (e.g., Ethernet, RS-485/RS-232 serial ports), and stored in on-board memory or cache.

- Output Display: Collected data is visualized on a high-resolution display (e.g., 10.4-inch touchscreen) in the form of graphs, charts, text, etc., while system status (e.g., operation, alarm, fault) is feedback via LED indicators or buzzers.

- Communication Links with Control Systems:

- Protocol Conversion: Supports multiple industrial communication protocols (e.g., Modbus RTU/TCP, PROFINET, EtherNet/IP). Through built-in protocol stack chips or software modules, user commands are converted into protocol formats recognizable by underlying devices, and vice versa. For example:

When an operator sets a "motor speed" parameter on the panel, the PP846A sends the command to the corresponding frequency converter via the Modbus TCP protocol.

Real-time data collected by sensors is processed by the controller and transmitted to the PP846A via the Ethernet interface for display. - Real-Time Performance Assurance: Low-latency data interaction is ensured through high-speed backplane buses or real-time operating systems (RTOS) to meet the real-time monitoring and control requirements of industrial scenarios (e.g., millisecond-level response).

2. Software Logic and Function Implementation

- Collaboration Between Firmware and Configuration Software:

- Firmware Program: Built-in dedicated firmware realizes basic functions (e.g., interface rendering, communication protocol parsing, data processing logic). The firmware is typically developed by ABB and can be upgraded via special tools (e.g., Control Builder M).

- Configuration Design: Users customize the panel interface (e.g., layout, button functions, data display format) and configure communication parameters (e.g., IP address, baud rate, slave address) via ABB Control Builder M or third-party configuration software. After the configuration file is downloaded to the PP846A, the panel operates according to the preset logic.

- Data Processing and Control Logic:

- Real-Time Database: A built-in small real-time database stores key process variables (PV), setpoints (SV), device status, etc., supporting fast read/write operations to respond to interface refreshes and control commands.

- Control Algorithm Integration: Some models support embedding simple control logic (e.g., PID adjustment parameter setting), allowing operators to adjust control parameters directly on the panel without using upper-level computer software. Complex control logic still relies on underlying controllers (e.g., AC800M CPU modules) for execution, with the PP846A serving only as a parameter transmission and status monitoring interface.

- Alarm and Security Mechanisms:

- Threshold Triggering: Data thresholds (e.g., temperature upper limit, pressure lower limit) are preset in the configuration software. When the collected data exceeds the thresholds, the PP846A triggers an alarm via a built-in logic processor, displaying a red warning on the interface and sounding a buzzer, while sending an alarm signal to the control system (e.g., via Modbus register setting).

- Permission Management: User accounts and password verification (e.g., hierarchical permissions: operator, engineer, administrator) restrict different users' access to critical operations (e.g., parameter modification, system reboot) to prevent misoperations or unauthorized access.

3. Industrial Environment Adaptability Design

- Anti-Interference and Reliability:

- Electrical Isolation: Communication interfaces and power modules adopt electrical isolation design to avoid external electromagnetic interference (EMI) affecting internal circuits, complying with IEC 61000 electromagnetic compatibility standards.

- Redundancy Mechanism: Redundant power input or communication links are supported in some scenarios (requiring matching redundant modules) to ensure system operation in case of single-point failures.

- Physical Structure and Environmental Compatibility:

- Mechanical Design: It adopts DIN rail mounting or panel embedded mounting, with a compact structure suitable for space constraints in control cabinets. The housing material is impact-resistant and dust-proof (protection class IP20), and it can operate stably in the temperature range of -20°C to +60°C.

- Thermal Management: Reasonable PCB layout and heat dissipation design prevent component overheating during long-term operation and extend hardware life.

4. Typical Workflow Example

Take the "temperature monitoring and control of a chemical reactor" scenario as an example:

- Data Acquisition: The PP846A reads real-time temperature data from a temperature sensor via the RS-485 interface using the Modbus RTU protocol, updating 10 times per second.

- Interface Display: The temperature value is displayed on the panel screen in digital and trend graph forms, while the preset temperature upper and lower limits (e.g., 100°C~150°C) are shown.

- User Operation: The operator inputs a new temperature setpoint (e.g., 120°C) via the touchscreen, and the PP846A sends the command to the AC800M controller via Ethernet.

- Control Execution: The controller adjusts the heating valve opening via a PID algorithm based on the deviation between the setpoint and real-time temperature. Parameters during adjustment (e.g., valve opening, PID parameters) are real-time feedback to the PP846A.

- Alarm Response: If the temperature exceeds 150°C, the PP846A interface flashes an alarm prompt, triggers the buzzer, and sends an alarm signal to the DCS system to notify engineers for handling.