Description

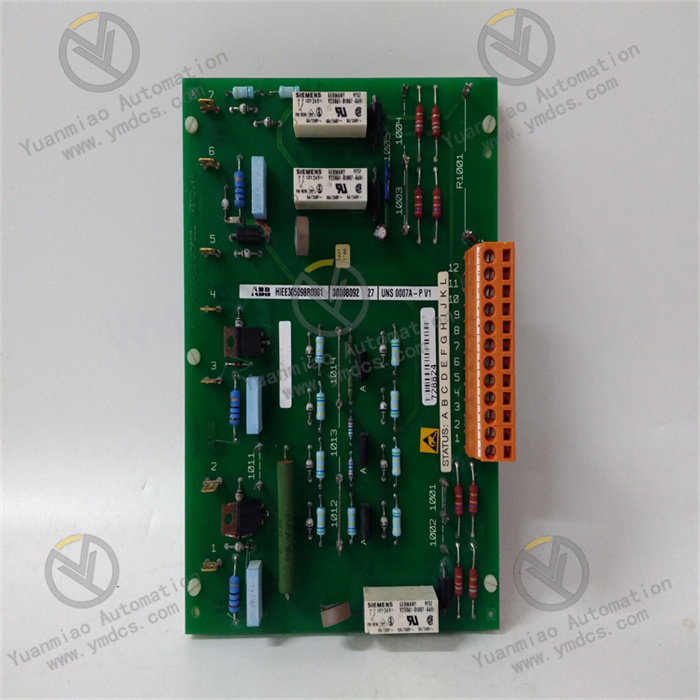

Functional Features Abundant Input and Output Interfaces: This module has 8 digital input channels and 8 digital output channels. The digital outputs include 8 DO+ outputs (L-grounded), 2 DO- outputs (S+ grounded), and 2 pulse outputs, which can meet the signal input and output requirements in various industrial automation control scenarios. High Reliability and Safety: Adopting strict quality control and safety protection mechanisms, it can cope with complex industrial environments and various abnormal situations, ensuring the normal operation of equipment and data security. All HIMATRIX systems are certified and can be used in SIL 3 and PL e (Cat. 4), as well as in SIL 4 environments compliant with CENELEC standards. Flexible Configuration and Expansion Capabilities: It can be customized according to user needs, supports multiple communication interfaces and protocols, and is convenient for connection and integration with other devices. It can be connected to HIMAX and HIMATRIX controllers via a secure Ethernet to expand the I/O level. Fault Diagnosis and Handling: It has a fault diagnosis function and displays the system status through LED indicators and other means, facilitating operators to quickly locate and solve faults. In case of a fault, the safety-related watchdog will set the output to a safe state to ensure system safety.

Technical Parameters

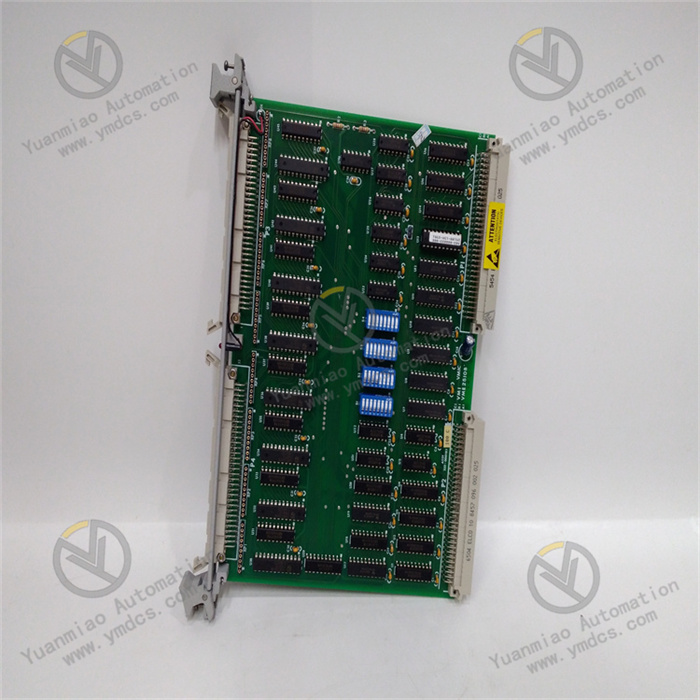

Microprocessor: Using an INTEL 386EX microprocessor, 32-bit, with a clock frequency of 25MHz.

Storage Capacity: The operating system flash EPROM is 1MB, the user program flash EPROM is 1MB, and the data SRAM is 1MB.

Interface Type: It has two electrically isolated serial interfaces RS 485 for communication with other devices.

Operating Voltage: Usually 24V DC, and the operating data is 5V/2A.

Space Requirement: It occupies 8SU of space.

Dimensions and Weight: The dimensions are approximately 23cm×5.5cm×12cm, and the weight is approximately 0.36kg.

Application Scenarios

Petrochemical Industry: In the processes of oil refining, chemical production, etc., it is used to monitor and control various process parameters such as temperature, pressure, flow rate, etc., to ensure the safe and stable operation of the production process.

Power Industry: It can be applied in places such as power plants and substations to monitor and control the operation status of the power system, realize functions such as fault protection and automatic reclosing, and ensure the reliability of power supply.

Pharmaceutical Industry: In the pharmaceutical production process, it is used to control the operation of production equipment, ensure the quality and safety of pharmaceutical production, and meet the strict regulatory requirements of pharmaceutical production.

Food and Beverage Industry: It is used for equipment control and process monitoring in the food and beverage production line, such as in the filling, packaging, and other links, to ensure the automation of the production process and the stability of product quality.

Installation and Maintenance Installation: It can be installed in a 19-inch sub-rack. During the installation process, relevant installation specifications and safety requirements should be followed to ensure that the module is firmly installed and the wiring is correct. Maintenance: Regularly inspect and maintain the module, including checking whether the hardware connections are loose, cleaning the surface dust of the module, checking whether the power supply is normal, etc. At the same time, according to the operation status of the system, the configuration of the module needs to be backed up and updated to ensure the stability and reliability of the system. The installation and configuration steps of HIMA F3 DIO 8/8 01 are as follows:

Installation Steps Preparation Work: Ensure that the installation environment meets the requirements of the module, such as the environmental temperature, humidity, etc. are within the specified range. Prepare the required tools, such as a screwdriver. Selection of Installation Location: Usually installed in a 19-inch sub-rack, an appropriate slot location can be selected according to the actual space and system layout, while considering the convenience of wiring and maintenance. Module Fixing: Insert the HIMA F3 DIO 8/8 01 module smoothly into the selected slot, and use screws or other fixing devices to firmly fix it to prevent the module from loosening. Connect the Power Supply: Connect the 24V DC power supply according to the requirements of the module instruction manual, ensure that the power connection is correct and stable, and pay attention to the positive and negative polarities. Connect the Input and Output Cables: According to the actual application requirements, connect the digital input signal sources (such as sensors, buttons, etc.) to the digital input channels of the module through cables, and connect the digital output signals to the corresponding actuators (such as relays, indicator lights, etc.). Note that the specifications and connection methods of the cables should meet the requirements of the module, and the cables should be sorted and labeled for subsequent maintenance.

Configuration Steps Selection of Configuration Tools: Generally use HIMA's dedicated configuration software, such as Silworx or Elop II Factory. Software Installation and Setup: Install the corresponding configuration software on the configuration computer and perform necessary settings according to the system requirements, such as communication parameters, device drivers, etc. Establish a Communication Connection: Establish a connection between the configuration computer and the control system where the HIMA F3 DIO 8/8 01 module is located through an appropriate communication interface (such as Ethernet, etc.) to ensure normal communication. Open the Configuration Software and Load Module Information: After opening the configuration software, load the relevant information of the HIMA F3 DIO 8/8 01 module, including the module type, the number of channels, functional characteristics, etc. Configure Digital Input Parameters: Find the configuration options for the digital input channels in the configuration software, and set relevant parameters according to the characteristics of the actual input signals, such as the input signal type (such as dry contacts, wet contacts), filtering time, signal status definition, etc. Configure Digital Output Parameters: For the digital output channels, set parameters such as the type of output signal (such as level output, pulse output), the initial state of the output value, the output state in case of a fault, etc. Configure Other Parameters: According to specific application requirements, it may also be necessary to configure the communication parameters, diagnostic parameters, safety-related parameters, etc. of the module to meet the overall functional and safety requirements of the system. Download the Configuration to the Module: After all parameters are configured, download the configuration information to the HIMA F3 DIO 8/8 01 module to make the module operate according to the configured parameters. Verify the Configuration: Input different signal states to check whether the output changes as expected to verify the correctness of the configuration. At the same time, observe the operation status indicator lights of the module to confirm whether the module is working properly.