Description

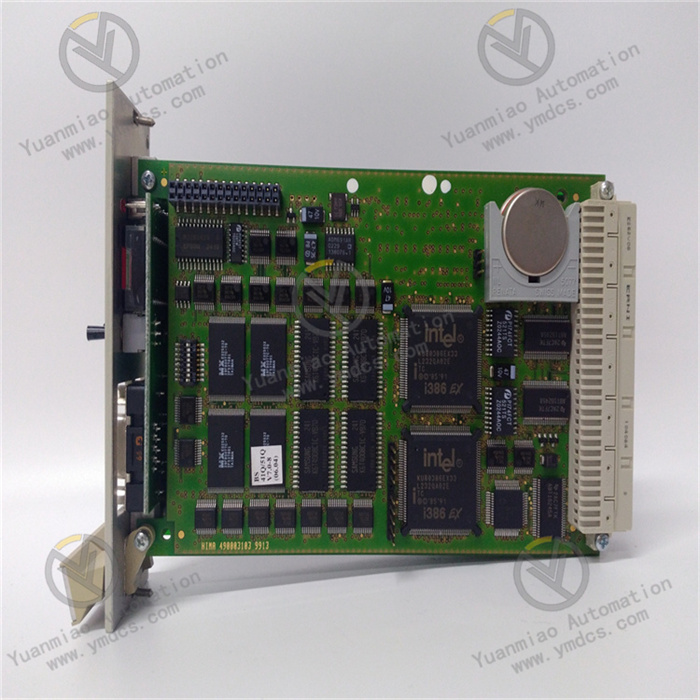

GE 8811-IO-DC 8811-IO-DC-01

I. Product Overview

II. Performance Parameters

Input parameters:

Input type: Supports DC digital input, and can access dry contact or wet contact signals. Dry contact input does not require an external power supply, and only transmits signals through the on-off state of the contacts; wet contact input requires an external specific DC voltage (such as 24V DC), and indicates the signal state through the presence or absence of voltage.

Number of input points: Generally, it is equipped with multiple input channels, with common configurations of 16 or 32 points (specifically subject to the actual product specifications). It can collect status signals of multiple on-site devices at the same time, meeting the needs of small and medium-sized industrial control scenarios.

Response time: The response speed of input signals is relatively fast, usually at the millisecond level (such as 1-10ms), which can quickly capture the status changes of on-site equipment and ensure that the control system obtains accurate information in a timely manner.

Input type: Supports DC digital input, and can access dry contact or wet contact signals. Dry contact input does not require an external power supply, and only transmits signals through the on-off state of the contacts; wet contact input requires an external specific DC voltage (such as 24V DC), and indicates the signal state through the presence or absence of voltage.

Number of input points: Generally, it is equipped with multiple input channels, with common configurations of 16 or 32 points (specifically subject to the actual product specifications). It can collect status signals of multiple on-site devices at the same time, meeting the needs of small and medium-sized industrial control scenarios.

Response time: The response speed of input signals is relatively fast, usually at the millisecond level (such as 1-10ms), which can quickly capture the status changes of on-site equipment and ensure that the control system obtains accurate information in a timely manner.

Output parameters:

Output type: Adopts DC digital output, commonly in the form of transistor output, which has the characteristics of fast switching speed and long service life. The output circuit is usually designed with a short-circuit protection function. When a short circuit occurs at the output end, it can quickly cut off the output to protect the module and external equipment.

Number of output points: Corresponding to the number of input points, it is generally 16 or 32 points, which can control the actions of multiple actuators at the same time, such as relays, solenoid valves, indicator lights, etc.

Output load capacity: Each output point can drive a load of a certain power. For example, the maximum load current can reach 0.5A-2A (specifically depending on the model), which can directly drive small actuators without additional power amplifying devices.

Output type: Adopts DC digital output, commonly in the form of transistor output, which has the characteristics of fast switching speed and long service life. The output circuit is usually designed with a short-circuit protection function. When a short circuit occurs at the output end, it can quickly cut off the output to protect the module and external equipment.

Number of output points: Corresponding to the number of input points, it is generally 16 or 32 points, which can control the actions of multiple actuators at the same time, such as relays, solenoid valves, indicator lights, etc.

Output load capacity: Each output point can drive a load of a certain power. For example, the maximum load current can reach 0.5A-2A (specifically depending on the model), which can directly drive small actuators without additional power amplifying devices.

Environmental parameters:

Operating temperature: Adapts to temperature changes in industrial sites. The operating temperature range is usually -20℃-60℃, and it can operate stably in cold outdoor equipment rooms or high-temperature production workshops.

Relative humidity: It can work in a relative humidity environment of 5%-95% (non-condensing), effectively preventing circuit faults caused by humidity, and ensuring reliable use in humid industrial environments (such as food processing workshops, sewage treatment plants).

Anti-electromagnetic interference: It complies with industrial electromagnetic compatibility standards (such as IEC 61000 series), has strong anti-electromagnetic interference ability, can resist electromagnetic interference generated by equipment such as motors and frequency converters in industrial sites, and ensures the accuracy of signal transmission.

Operating temperature: Adapts to temperature changes in industrial sites. The operating temperature range is usually -20℃-60℃, and it can operate stably in cold outdoor equipment rooms or high-temperature production workshops.

Relative humidity: It can work in a relative humidity environment of 5%-95% (non-condensing), effectively preventing circuit faults caused by humidity, and ensuring reliable use in humid industrial environments (such as food processing workshops, sewage treatment plants).

Anti-electromagnetic interference: It complies with industrial electromagnetic compatibility standards (such as IEC 61000 series), has strong anti-electromagnetic interference ability, can resist electromagnetic interference generated by equipment such as motors and frequency converters in industrial sites, and ensures the accuracy of signal transmission.

III. Functional Features

Diagnosis and status indication: The module is equipped with LED indicators, which can display the working status of each input/output channel (such as on, off) as well as the power status and fault status of the module in real time. By observing the indicators, operators can quickly judge the operation of the module and connected equipment, facilitating fault Investigation and maintenance. Some models also have a self-diagnosis function, which can detect internal circuit faults of the module and upload fault information to the control system through the communication interface to realize remote diagnosis.

Fast signal processing: It adopts a high-performance microprocessor and a dedicated signal processing circuit, which can quickly collect, filter and process input signals, and respond to output control instructions in a timely manner. This fast processing capability ensures the response speed of the module in real-time control scenarios, meeting the requirements of industrial production for control accuracy and timeliness.

Flexible communication interface: It supports communication with control systems such as PLC and industrial computers. Common communication interfaces include RS-485 (supporting Modbus RTU protocol) or Ethernet interface (supporting Modbus TCP/IP protocol), etc. Through the communication interface, the control system can configure parameters, read signals and control outputs of the module, realizing centralized monitoring and remote management.

Compact structure design: It adopts standardized guide rail installation or panel installation, with a compact structure and small volume, saving installation space. The wiring terminals of the module usually adopt a plug-in design, which is convenient for on-site wiring and maintenance, and improves installation efficiency.