Description

I. Product Positioning and Application Scenarios

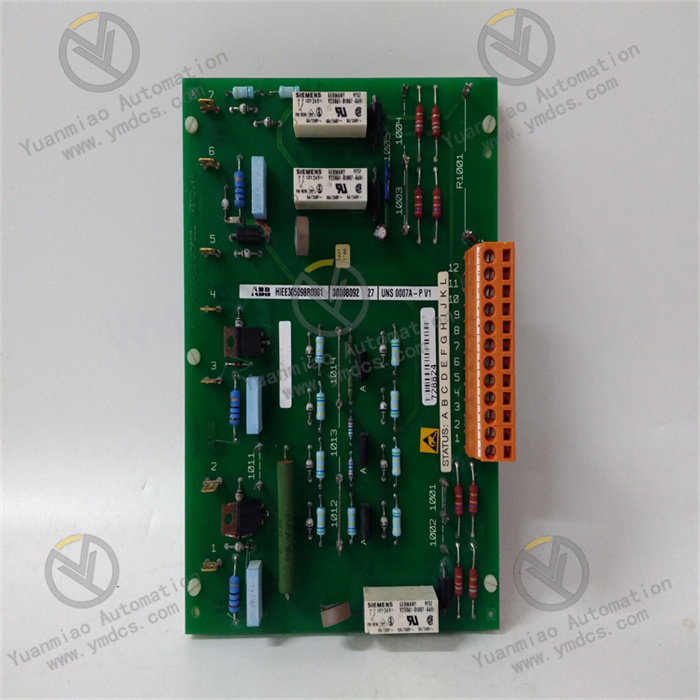

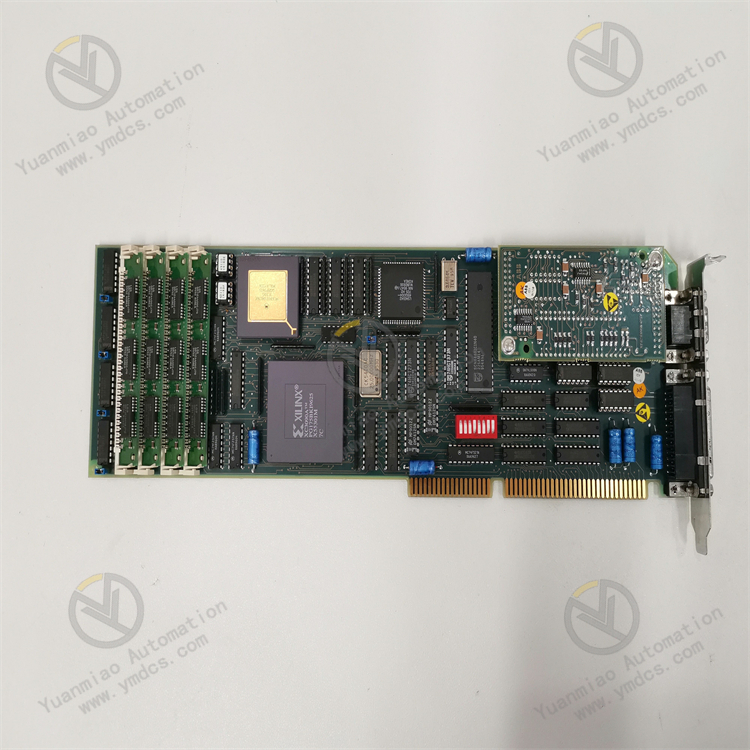

1. Product Type

Series Affiliation: Likely belongs to the Distributed Processing Unit (DSPU) of ABB's AC 800M controller system, used for core computation and logical control in industrial automation control systems.

Functional Positioning: As a central processing unit (CPU) module for PLC/DCS systems, responsible for executing user programs, data processing, communication coordination, and real-time control tasks.

Functional Positioning: As a central processing unit (CPU) module for PLC/DCS systems, responsible for executing user programs, data processing, communication coordination, and real-time control tasks.

2. Typical Application Scenarios

- Process Automation: Control of production lines in industries such as chemicals, petroleum, power, and pharmaceuticals.

- Mechanical Automation: Logical control for CNC machine tools, robot control systems, and packaging machinery.

- Building Automation: Energy management systems (BMS) or HVAC control in large-scale buildings.

- System Architecture: Supports redundant configurations (e.g., dual CPU hot standby) to enhance system reliability, suitable for scenarios requiring high availability.

II. Technical Parameters

1. Hardware Configuration

| Parameter | Typical Value |

|---|---|

| Processor | 32-bit RISC processor (e.g., PowerPC architecture) |

| Memory | - Program memory: 512 KB ~ 2 MB (Flash) - Data memory: 256 KB ~ 1 MB (RAM) |

| Communication Interfaces | - Ethernet (10/100 Mbps, supporting PROFINET, Modbus TCP) - RS-485/RS-232 (for programming or local communication) - Dedicated bus interface (e.g., ABB's S2 bus for connecting I/O modules) |

| I/O Expansion Capability | Supports connection of multiple distributed I/O modules (e.g., DI/DO, AI/AO, counter modules, etc.), with a maximum of hundreds of points |

| Power Supply Voltage | DC 24V ±10% or AC 100-240V (specific to the model) |

| Power Consumption | Typical 5-10 W |

| Mounting Method | DIN rail mounting or panel mounting |

| Dimensions (W×H×D) | Approximately 100 mm × 150 mm × 120 mm (compact design) |

| Protection Level | IP20 (indoor dust protection) |

| Operating Temperature | -20°C ~ +60°C (industrial grade, supporting wide temperature operation) |

| Storage Temperature | -40°C ~ +85°C |

2. Software and Functional Features

- Programming Languages: Supports IEC 61131-3 standard programming languages (Ladder Diagram, Structured Text, Function Block Diagram, etc.).

- Real-Time Operating System (RTOS): Ensures deterministic and real-time control tasks (e.g., task cycles configurable in milliseconds).

- Communication Protocols:

- Industrial buses: PROFINET, EtherCAT, Modbus TCP, CANopen, etc.

- Field buses: FF (Foundation Fieldbus), Profibus DP (requires expansion modules).

- Functional Support:

- Logical control, sequential control, PID regulation (built-in PID function blocks).

- Data logging and trend analysis (supports local storage or Ethernet transmission to SCADA systems).

- Fault diagnosis and self-diagnosis (e.g., alarms for CPU faults, communication interruptions, memory errors, etc.).

- Firmware upgrade: Supports online updates via programming software (e.g., ABB Automation Builder).

- Safety Features:

- Complies with IEC 61508 standards (requires safety modules to achieve SIL2/SIL3-level safety control).

- Supports redundant configurations (e.g., dual CPUs running synchronously with automatic failover during faults).

III. Supporting Systems and Programming Tools

1. Compatible Systems

- Controller Platforms: ABB AC 800M controllers, PLCnext technology platforms, etc.

- I/O Modules: ABB S800 I/O series modules (e.g., DI810, DO810, AI810, etc.).

- Human-Machine Interfaces (HMI): ABB Panel PC, third-party SCADA software (e.g., Wonderware, WinCC).

2. Programming and Debugging Tools

- Software Tools:

- ABB Automation Builder: Used for system configuration, programming, debugging, and simulation.

- PC Studio: Legacy programming software suitable for traditional PLC program development.

- Debugging Functions:

- Online variable monitoring, forced I/O status, breakpoint debugging.

- Real-time fault log viewing via diagnostic buffers.

IV. Fault Diagnosis and Maintenance Recommendations

1. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Power indicator not lit | Abnormal power supply, faulty module power interface | Check power voltage, replace power cables or modules |

| Communication interruption | Damaged network cable, IP address conflict, protocol errors | Replace network cables, reconfigure IP or communication parameters |

| Abnormal program operation | Memory errors, incompatible firmware versions | Restart the module, upgrade firmware, or restore factory settings |

| No response from I/O | I/O bus faults, unconfigured modules | Check bus connections, reconfigure I/O modules |

| Overheat alarm | Poor heat dissipation, excessively high ambient temperature | Clean cooling vents, improve ventilation, or reduce ambient temperature |

2. Maintenance Recommendations

- Regular Inspections:

- Ensure the module is securely mounted without looseness or vibration.

- Clean the housing and cooling vents to prevent dust accumulation affecting heat dissipation.

- Data Backup:

- Regularly back up user programs and configuration files (export via Automation Builder).

- It is recommended to use version management tools (e.g., Git) to manage program changes.

- Firmware Management:

- Monitor official firmware updates from ABB to fix known issues or add new functions.

- Ensure existing programs are backed up before upgrading and test the compatibility of new versions.