Description

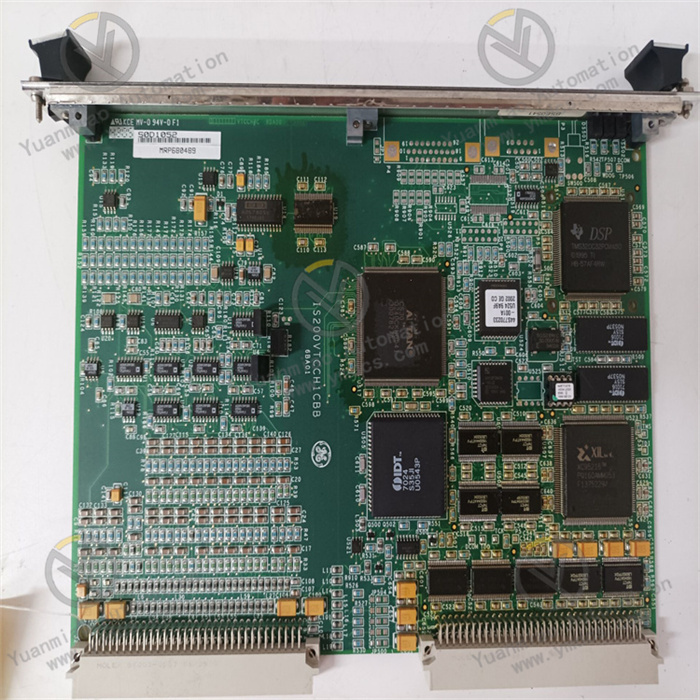

GE IS415UCVGH1A V7666-111000

I. Product Overview

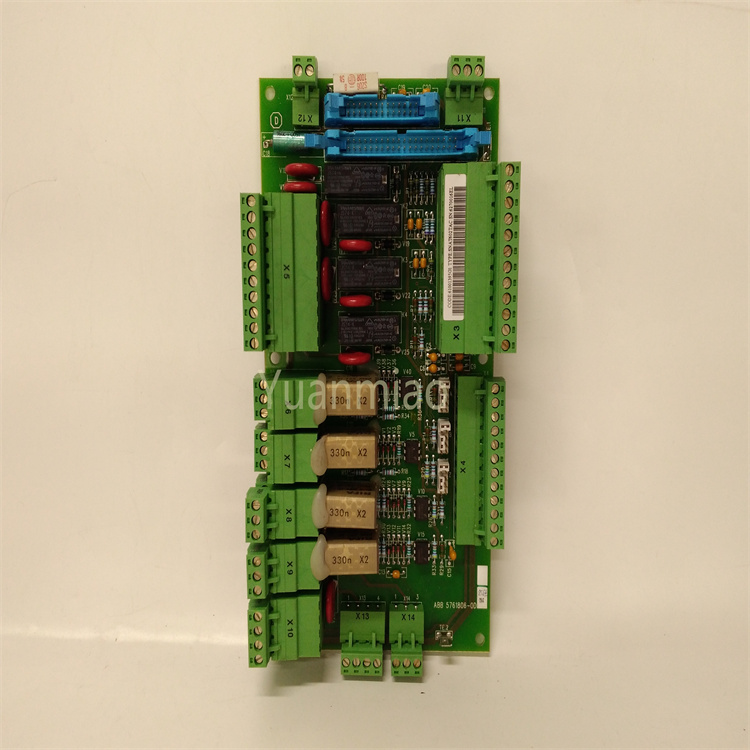

In terms of hardware design, the module adopts a compact structural design, and its overall dimensions are optimized, enabling it to adapt to the limited installation space in the control cabinet and facilitating combined installation with other equipment. The shell is made of high-strength industrial-grade materials, with good anti-vibration, anti-impact, and dust-proof performance. It can operate stably for a long time in dusty and frequently vibrating industrial environments, effectively protecting internal circuit components and ensuring the service life and operational reliability of the module.

In terms of functional positioning, the IS415UCVGH1A module focuses on signal acquisition and control command output in industrial sites. It can accurately receive signals from various sensors, such as converted signals of physical quantities like temperature, pressure, and flow. At the same time, it issues control commands to actuators according to preset control logic to achieve precise regulation of industrial equipment, serving as a key bridge connecting the on-site perception layer and the control layer.

II. Performance Parameters

- Operating Voltage: Supports industrial standard DC voltage input, commonly 24V DC. This voltage specification matches most sensors, actuators, and power supply systems in industrial sites, facilitating system integration, ensuring the module can stably obtain working power, and guaranteeing the normal operation of various functions.

- Input and Output Characteristics: It has a specific number of input and output channels (the specific number needs to refer to the product manual). The input channels are compatible with various types of signals, such as 4-20mA current signals and 0-10V voltage signals, which can meet the signal access needs of different sensors. The output channels have a certain driving capability and can directly drive small relays, solenoid valves, and other actuators. The output current is usually within a certain range (such as 1A-5A), and the specific value depends on the model.

Environmental Adaptability:

- Operating Temperature: It can work stably within the temperature range of -20℃ to +60℃, adapting to common temperature changes in industrial production workshops. Whether in cold winters or hot summers, it can maintain stable performance, ensuring that the control process is not affected by temperature fluctuations.

- Relative Humidity: It can operate normally in a relative humidity environment of 5%-95% (non-condensing), suitable for humid industrial places such as food processing workshops and water treatment plants. It effectively prevents circuit faults caused by humidity and ensures the long-term reliable operation of the module.

- Anti-electromagnetic Interference: It meets industrial-grade electromagnetic compatibility standards and has strong anti-electromagnetic interference ability. It can resist electromagnetic interference generated by motors, frequency converters, high-voltage equipment, etc. in industrial sites, ensuring the accuracy of signal transmission and the reliable execution of control commands, and avoiding misoperations caused by interference.

Response Speed:

The module has fast signal processing and response speed. The response time of input signals is usually at the millisecond level (the specific value needs to refer to the product manual). It can quickly capture changes in on-site signals and output corresponding control commands in a timely manner, meeting the real-time requirements of industrial automation systems and ensuring timely regulation of equipment.

The module has fast signal processing and response speed. The response time of input signals is usually at the millisecond level (the specific value needs to refer to the product manual). It can quickly capture changes in on-site signals and output corresponding control commands in a timely manner, meeting the real-time requirements of industrial automation systems and ensuring timely regulation of equipment.

III. Functional Characteristics

It has precise signal processing capability, which can filter, amplify, convert, and otherwise process input analog or digital signals, remove noise interference in the signals, improve the accuracy and stability of the signals, and provide reliable original data for the control system. For example, when collecting signals from pressure sensors, it can effectively filter out interference signals caused by pipeline vibration, ensuring the true reflection of pressure data.

It supports range calibration and linearization processing of input signals. Users can set parameters for the module according to the characteristics of actual sensors, establishing an accurate corresponding relationship between the collected signals and actual physical quantities, improving measurement accuracy, and meeting the needs of high-precision control scenarios.

Control Logic Execution:

It has built-in programmable control logic. Users can program and configure parameters for the module through dedicated programming software to realize customized control strategies. For example, according to the deviation between the input temperature signal and the set value, the output control quantity is automatically adjusted to achieve closed-loop control of heating equipment, keeping the temperature within the set range.

It supports linkage control with other control equipment. It receives commands from the upper-level control system through communication interfaces, executes corresponding operations according to the commands, and feeds back its own operating status and collected data to the upper-level system, realizing the collaborative work of the entire industrial automation system.

It has built-in programmable control logic. Users can program and configure parameters for the module through dedicated programming software to realize customized control strategies. For example, according to the deviation between the input temperature signal and the set value, the output control quantity is automatically adjusted to achieve closed-loop control of heating equipment, keeping the temperature within the set range.

It supports linkage control with other control equipment. It receives commands from the upper-level control system through communication interfaces, executes corresponding operations according to the commands, and feeds back its own operating status and collected data to the upper-level system, realizing the collaborative work of the entire industrial automation system.

Status Monitoring and Diagnosis:

It has a complete status monitoring function, which can real-time monitor the operating status of the module itself, such as power supply voltage and communication status, and indicate the status through indicators or communication methods, facilitating operators to intuitively understand the working condition of the module.

It has a certain self-diagnosis capability. When the module fails or is abnormal, such as input signal overrun or communication interruption, it can timely send out alarm signals and record fault information, facilitating maintenance personnel to quickly locate and troubleshoot faults, and shortening system downtime.

It has a complete status monitoring function, which can real-time monitor the operating status of the module itself, such as power supply voltage and communication status, and indicate the status through indicators or communication methods, facilitating operators to intuitively understand the working condition of the module.

It has a certain self-diagnosis capability. When the module fails or is abnormal, such as input signal overrun or communication interruption, it can timely send out alarm signals and record fault information, facilitating maintenance personnel to quickly locate and troubleshoot faults, and shortening system downtime.

IV. Application Scenarios

In automated production lines such as automobile manufacturing and electronic production, the IS415UCVGH1A module can be used to collect various process parameters on the production line, such as welding temperature, assembly pressure, and conveyor belt speed. According to preset control logic, it controls the actions of corresponding equipment, such as adjusting welding current, controlling the tightness of clamping devices, and regulating the running speed of the conveyor belt, ensuring the stable progress of the production process and improving product quality and production efficiency.

It can be used for equipment status monitoring of the production line. By collecting signals such as the operating current and temperature of the equipment, it judges whether the equipment is in normal operation. When abnormal equipment is detected, it timely sends out alarm signals and controls the equipment to stop, avoiding equipment damage and production accidents.

Process Control Field:

In process control scenarios such as chemical industry, petroleum, and water treatment, the module can be used to collect key parameters such as the temperature, pressure, liquid level of reaction kettles, and the flow rate of pipelines. It transmits these parameters to the control system and receives commands from the control system to control the opening of valves, the rotation speed of pumps, etc., realizing precise regulation of the production process, ensuring that process parameters are stable within the specified range, and guaranteeing production safety and product quality.

For example, in the water treatment process, the module collects the liquid level signal of the pool. When the liquid level is lower than the set value, it controls the water inlet valve to open; when the liquid level reaches the set value, it controls the valve to close, realizing automatic control of the pool liquid level.

In process control scenarios such as chemical industry, petroleum, and water treatment, the module can be used to collect key parameters such as the temperature, pressure, liquid level of reaction kettles, and the flow rate of pipelines. It transmits these parameters to the control system and receives commands from the control system to control the opening of valves, the rotation speed of pumps, etc., realizing precise regulation of the production process, ensuring that process parameters are stable within the specified range, and guaranteeing production safety and product quality.

For example, in the water treatment process, the module collects the liquid level signal of the pool. When the liquid level is lower than the set value, it controls the water inlet valve to open; when the liquid level reaches the set value, it controls the valve to close, realizing automatic control of the pool liquid level.

Intelligent Building System:

In the air conditioning and ventilation system of intelligent buildings, the IS415UCVGH1A module can collect indoor parameters such as temperature, humidity, and air quality. Based on these parameters, it controls the operating status of the air conditioning unit, such as adjusting cooling capacity, heating capacity, and fan speed, keeping the indoor environment within a comfortable range, and achieving the purpose of energy conservation and consumption reduction.

In the lighting system of buildings, it can control the switching and brightness adjustment of lighting fixtures by collecting light intensity and personnel activity signals, realizing intelligent lighting control and improving energy utilization efficiency.

In the air conditioning and ventilation system of intelligent buildings, the IS415UCVGH1A module can collect indoor parameters such as temperature, humidity, and air quality. Based on these parameters, it controls the operating status of the air conditioning unit, such as adjusting cooling capacity, heating capacity, and fan speed, keeping the indoor environment within a comfortable range, and achieving the purpose of energy conservation and consumption reduction.

In the lighting system of buildings, it can control the switching and brightness adjustment of lighting fixtures by collecting light intensity and personnel activity signals, realizing intelligent lighting control and improving energy utilization efficiency.