Description

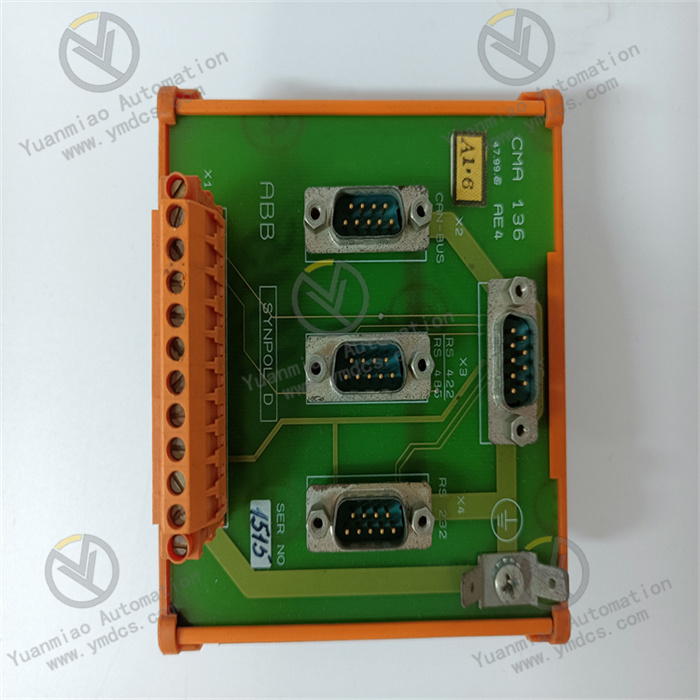

ABB CI858-1 3BSE018137R1

I. Product Overview

ABB CI858-1 3BSE018137R1 is a high-performance communication interface module, whose core function is to serve as a data communication bridge between the controller and external devices. This module achieves efficient data interaction with the AC 800M main controller via the CEX bus, and supports multiple industrial communication protocols at the same time. It can flexibly connect with various devices such as drives, remote I/O modules, sensors, actuators and upper monitoring systems, realizing real-time data transmission, remote monitoring, command issuing and collaborative device control.

II. Functional Features

1. Multi-protocol Compatibility and Multi-mode Communication Capability

2. High-reliability Design and Electrical Protection

3. Comprehensive Fault Diagnosis and Status Monitoring

4. Flexible Expansion and Wide Adaptability

5. Convenient Configuration and Operation & Maintenance

III. Technical Parameters

1. Basic Parameters

- Model: CI858-1

- Ordering Code: 3BSE018137R1

- Brand: ABB

- Product Type: Communication Interface Module

- Applicable Systems: ABB AC 800M Controller, 800xA DCS System (supporting V6.0.3.3 and above versions)

- Mounting Compatibility: Suitable for AC 800M controller rack and FLD distributed rack

- Core Chip: Intel 82852GM+ICH4

- Memory Specification: 512MB DDR 266MHz (maximum dynamic shared video memory: 64MB)

2. Communication Parameters

- Supported Protocols: Modbus TCP, Profibus DP, DriveBus, I/O Bus, PC Tool, TCP, UDP, IP, ICMP, ARP

- Communication Interfaces: 1×10M/100Mbps Ethernet interface (RJ45), 6 serial ports, 4 USB interfaces, 1 PS/2 KB/MS interface, CF card slot, CEX-Bus interface

- Data Transmission Capability: High-speed real-time transmission

- Number of Supported Slaves: Adjustable according to protocol type and system configuration

- Maximum Concurrent Connections: ≥100

3. Power Supply Parameters

- Power Supply Mode: Powered via CEX bus (+24V DC)

- Power Consumption: Typical value 5W

- Power Supply Protection: Equipped with overvoltage protection, reverse connection protection and electrostatic protection functions

- Watchdog: Built-in watchdog timer

- Redundant Power Supply: Support for CEX bus redundant power supply expansion

4. Environmental Parameters

- Operating Temperature: -25°C ~ 60°C (wide temperature range for harsh environments)

- Storage Temperature: -40°C ~ 85°C

- Relative Humidity: 5% ~ 95% (non-condensing)

- Protection Grade: IP20 (compliant with EN 60529 standard)

- Altitude: ≤2000m (derating required if exceeded)

- Pollution Degree: Degree 2 (compliant with IEC 61131-2 standard)

- Electromagnetic Compatibility: Compliant with EN 55011/EN 55022 Class A and EN 61000-4 series standards

5. Physical Parameters

- Mounting Method: Standard 35mm DIN rail mounting or plug-in rack mounting

- Dimensions: 59mm (width) × 186mm (height) × 127mm (depth)

- Net Weight: Approximately 0.7 kg

- Housing Material: Industrial-grade flame-retardant ABS plastic

- LED Indicators: Power Light (PWR), Run Light (RUN), Communication Activity Light (ACT), Fault Light (FAULT)

- User I/O Pins: 94

IV. Working Principle

The core working logic of the ABB CI858-1 3BSE018137R1 module is "Controller Interaction - Protocol Conversion - Multi-mode Communication - Status Feedback and Fault Protection". It realizes efficient data interaction between the controller and various external devices through the collaboration of multiple links. The specific working process is as follows:

Controller Interaction: The module establishes a stable connection with the AC 800M main controller via the CEX bus, receives control commands and communication parameter configuration information issued by the controller, and feeds back the operation data and status information uploaded by external devices to the controller, realizing efficient two-way data interaction.

Protocol Conversion: The built-in dedicated protocol processing unit converts the internal data format of the controller into the standard format of industrial protocols such as Modbus TCP, Profibus DP, DriveBus, etc., to ensure that the data can be recognized by external devices or upper systems. At the same time, it reversely converts various protocol data uploaded by external devices into a format parsable by the controller, realizing compatible transmission of cross-device and cross-protocol data.

Multi-mode Communication: It establishes connections with various external devices through rich interfaces such as Ethernet interface, serial port and USB, completes real-time data transmission (such as controller's control commands for drives and sensor measurement data) according to the preset communication rate and data interaction cycle, supports TCP connection-oriented reliable transmission and UDP connectionless fast transmission, and can flexibly select the transmission mode according to the data type.

- Status Feedback and Fault Protection: It real-timely monitors the communication link status, data transmission error rate, interface operation status and module self-status. When faults such as communication interruption, interface failure and data transmission abnormality are detected, it immediately issues an alarm via LED indicators and uploads fault information to the controller. The watchdog timer real-timely monitors the module operation status and automatically triggers the reset mechanism when an abnormality occurs, ensuring stable system operation and uninterrupted production control.

V. Common Fault Troubleshooting

| Fault Phenomenon | Possible Causes | Troubleshooting Methods |

|---|---|---|

| Power Light (PWR) not on, module unresponsive | Backplane bus power supply fault, module not fully installed, internal power supply unit of the module damaged | Check whether the system power supply is normal and whether the CEX bus supply voltage is +24VDC; re-plug the module to ensure it is fully installed with good pin contact; if the above checks are normal but the module is still unresponsive, contact ABB official after-sales service to repair the internal power supply unit or watchdog timer function of the module |

| Ethernet LINK light not on, network connection failed | Damaged/loose Ethernet cable, switch port failure, incorrect IP address configuration | Check whether the Ethernet cable is tightly connected and replace the damaged cable; test whether the switch port is normal and replace it with a spare port; check the module's IP address, subnet mask and gateway configuration to ensure they match the network segment and have no conflicts |

| Data transmission interruption or severe packet loss | Excessive network load, poor cable shielding, electromagnetic interference, mismatched communication rate | Troubleshoot network load; if it exceeds 80%, optimize the network architecture (such as adding switches, splitting network segments); check the grounding condition of the cable shielding layer and replace unshielded cables with shielded ones; troubleshoot electromagnetic interference sources and take shielding protection measures; set the communication rate to auto-negotiation mode to ensure the module's rate matches that of the switch |

| Redundancy switching failure | Incorrect redundancy parameter configuration, standby port/network failure, abnormal synchronization link | Re-check and correct redundancy configuration parameters (such as switching conditions, delay time, etc.); check the status of standby ports, standby networks and switches to ensure the standby link is normal; check the wiring of the master-standby synchronization link and repair loose or damaged links |

| PROFINET IO slave fails to go online | Mismatched slave device address, protocol type or parameter configuration, slave device fault, incorrect data mapping relationship, poor interface connection | Check the address, protocol type and parameter configuration of the slave device to ensure they are consistent with the configuration; test the slave device individually to troubleshoot equipment faults; check the data mapping relationship (input/output byte length, address offset) and interface connection status, and correct configuration errors or connection problems |