Description

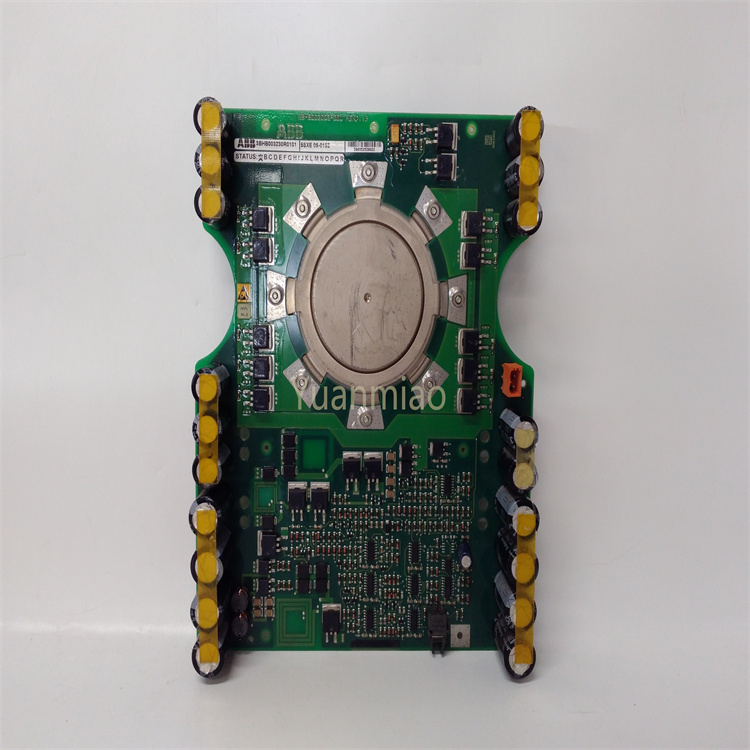

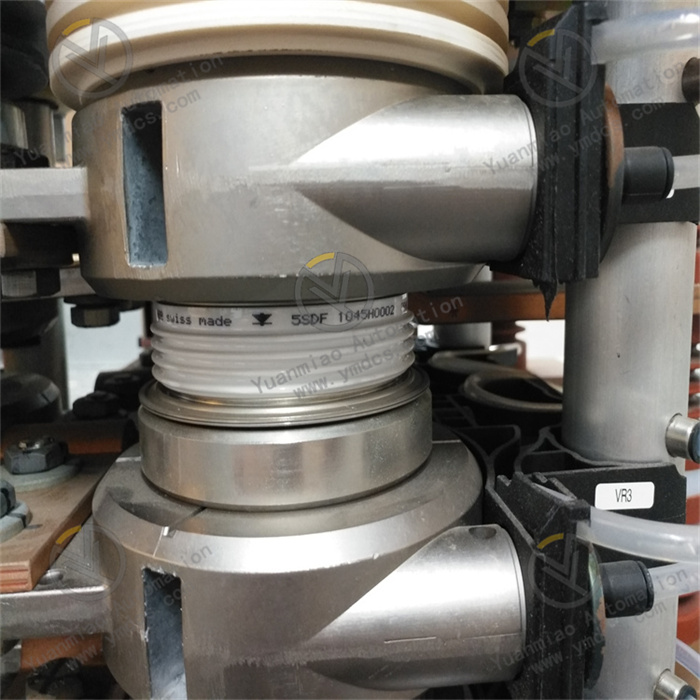

ABB 5SHX14H4502 High-Voltage Thyristor Module

I. Core Positioning and Application Fields

Positioning:

Belongs to ABB's power semiconductor product line and serves as a core component in high-voltage direct current (HVDC) transmission and industrial high-power converter fields. Adopts a press-fit ceramic package design, combining high reliability with efficient heat dissipation capabilities.

Belongs to ABB's power semiconductor product line and serves as a core component in high-voltage direct current (HVDC) transmission and industrial high-power converter fields. Adopts a press-fit ceramic package design, combining high reliability with efficient heat dissipation capabilities.

Application Scenarios:

- Power Systems

- HVDC converter valves (e.g., submarine cable transmission connecting onshore grids with offshore wind power).

- Flexible AC transmission systems (FACTS), static var compensators (SVC), static synchronous compensators (STATCOM).

- Industrial Drives

- Frequency conversion drive systems for large motors (synchronous/asynchronous motors) in steel and papermaking industries (e.g., mill drives, fan control).

- Solid-state circuit breakers (SSCB), high-voltage motor soft starters.

- Renewable Energy

- High-voltage side power conversion in photovoltaic/wind converters (requires multi-module series connection technology).

II. Key Functions and Technical Characteristics

- Electrical Performance

- Gate trigger current (Igt): ≤ 200 mA, trigger voltage (Vgt): ≤ 5 V, supporting high-precision pulse control (e.g., via ABB 5SDD series trigger units).

- Average on-state current (IT(AV)): 1400 A (rated condition, sinusoidal half-wave).

- Non-repetitive surge current (ITSM, 8/20μs pulse): 30 kA, capable of withstanding short-term fault current impacts.

- Off-state repetitive peak voltage (VDRM/VRRM): 4500 V, suitable for 3-10 kV high-voltage scenarios.

- Rated Voltage:

- Current Handling Capacity:

- Trigger Characteristics:

- Physical Design and Reliability

- Some models integrate temperature sensors for overheat warning; requires external fast fuses (e.g., ABB semiconductor protection fuses) and surge arresters for overcurrent/overvoltage protection.

- Built-in large-area copper substrate, supporting water or air cooling (requires ABB water-cooled plates or external radiators). Junction temperature range: -40°C ~ +125°C, ensuring long-term full-load operation.

- Press-fit ceramic package (planar structure), diameter ~120 mm, thickness ~40 mm, with high mechanical strength (vibration/impact resistance) and electrical insulation.

- Package Type:

- Heat Dissipation Design:

- Protection Functions:

- System Compatibility

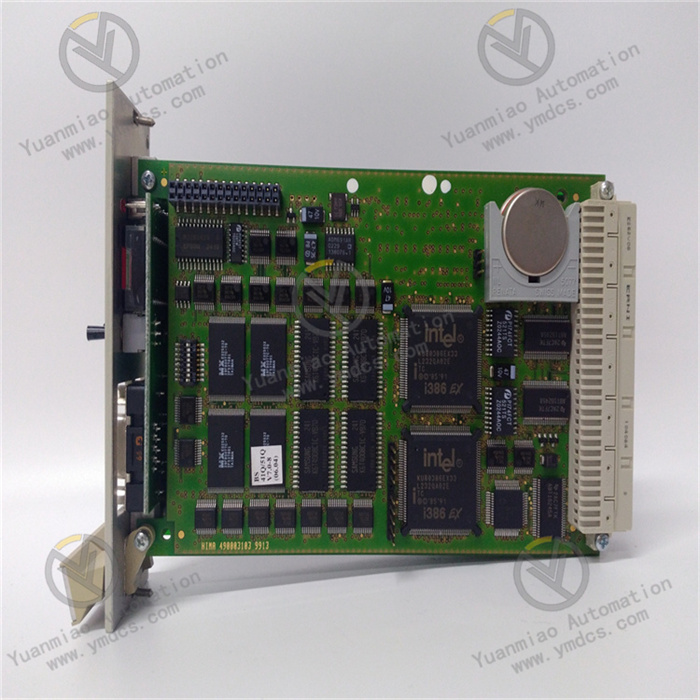

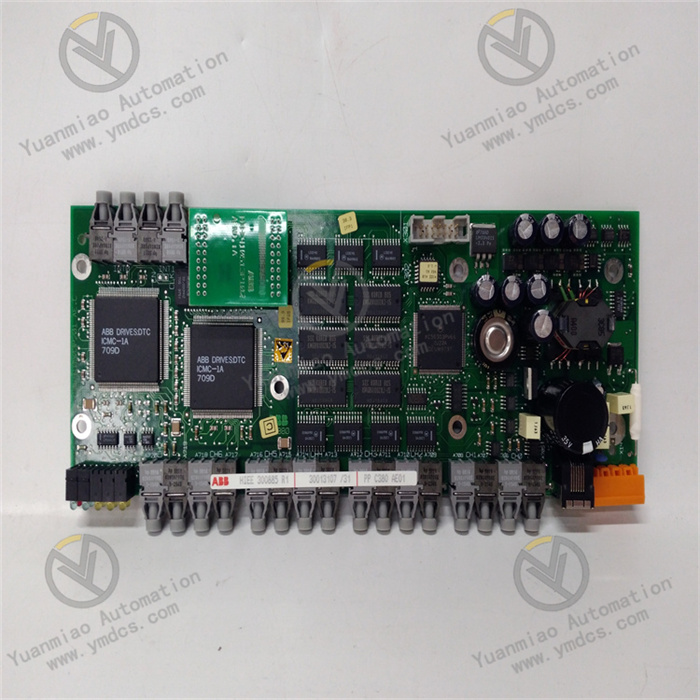

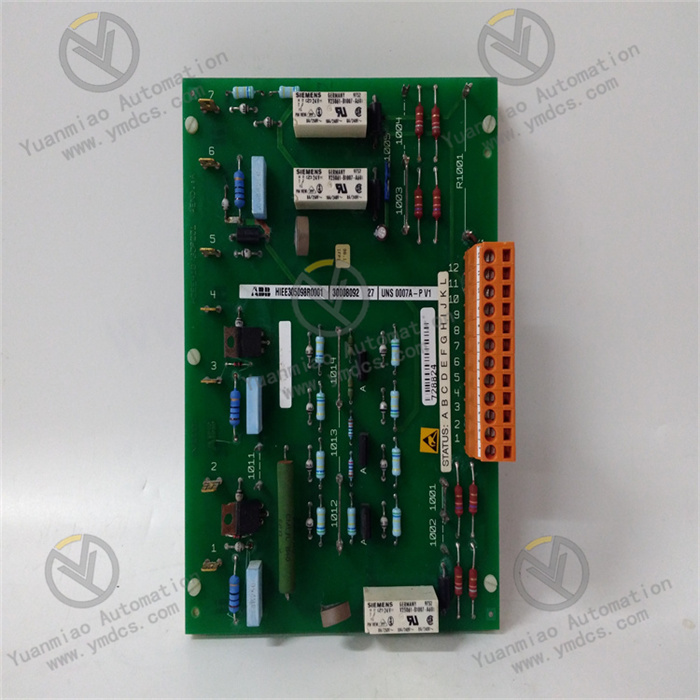

- Compatible with ABB PCS 600 series controllers, third-party PLC or DSP platforms for closed-loop control and real-time monitoring.

- Supports multi-module series (voltage scaling) or parallel (current scaling) to form valve stacks, suitable for complex systems like HVDC converter valves.

- Modular Expansion:

- Control Adaptability:

III. Technical Parameters

| Parameter | Value/Description |

|---|---|

| Rated off-state voltage (VDRM) | 4500 V |

| Average on-state current (IT(AV)) | 1400 A (rated condition) |

| Surge current (ITSM) | 30 kA (8/20μs pulse) |

| Gate trigger current/voltage | Igt ≤ 200 mA, Vgt ≤ 5 V |

| Junction temperature range | -40°C ~ +125°C |

| Package type | Press-fit ceramic package (planar) |

| Dimensions (Diameter × Thickness) | ~120 mm × 40 mm |

IV. Installation and Maintenance Key Points

- Installation Specifications

- Use copper busbars or large-section cables for the main circuit (reducing impedance). Route gate signal wires independently to resist electromagnetic interference (EMI).

- Apply thermal grease or graphite pads between the module and radiator. Bolt torque must follow the manual (e.g., 25 N·m) to avoid stress damage to the ceramic package.

- Mechanical Installation:

- Electrical Connections:

- Maintenance and Fault Troubleshooting

- Replace the entire module if damaged (e.g., breakdown), and check drive circuits (e.g., abnormal trigger pulses) and protection components (fuses, surge arresters) for failure.

- Use a thyristor tester to measure parameters like forward voltage drop and off-state resistance, comparing with factory data to assess aging.

- Visually inspect the module surface for cracks or ablation; monitor junction temperature (≤125°C) via infrared thermometry. Check water cooling system flow/pressure or fan operation.

- Routine Monitoring:

- Performance Testing:

- Fault Handling:

V. Supporting Products and Alternatives

- Driving and Protection:

- Trigger units: ABB 5SDD series (e.g., 5SDD1105).

- Cooling systems: ABB water-cooled plates, air-cooled radiators.

- Protection components: ABB semiconductor protection fuses (e.g., 3NE series), zinc oxide surge arresters.

- Alternative Models:

- For higher voltage/current ratings, consider upgraded models in ABB's 5SHX series (e.g., 5SHX16H4502 with 1600 A current capacity) or high-voltage thyristor modules from other brands (e.g., Infineon, Mitsubishi), ensuring compatibility in electrical parameters and mechanical interfaces.