Description

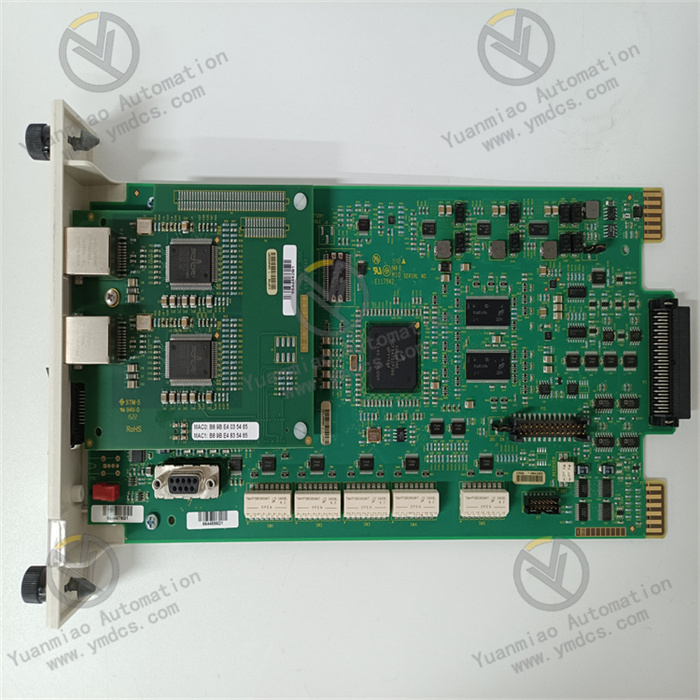

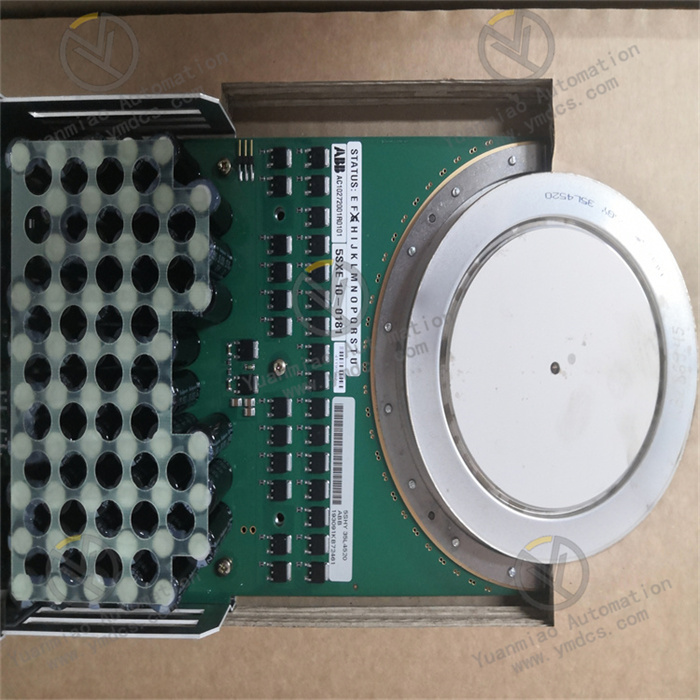

Functional Features Analog Input Function: It is mainly used for receiving and processing analog signals. It can accurately collect analog data from various sensors, such as signals from temperature, pressure, flow rate sensors, etc., and convert them into digital signals for the control system to process and analyze. Support for Multiple Input Signal Types: It can be compatible with various types of analog input signals. Commonly, there are 4 - 20mA current signals, 0 - 10V voltage signals, etc. This enables it to adapt to the output characteristics of different sensors and meet the application requirements of various industrial sites. High-precision Measurement and Conversion: It has high measurement precision and accurate signal conversion ability. It can precisely convert the input analog signals into digital quantities, providing accurate data for the control system and helping to achieve precise process control and monitoring. Diagnosis and Alarm Function: It has a self-diagnosis function and can monitor its own working status in real time. When abnormal situations are detected, such as signal loss, sensor failure, etc., it can promptly send out alarm information, facilitating maintenance personnel to quickly locate and solve problems, and improving the reliability and stability of the system.

Technical Characteristics Support for Communication Protocols: It supports multiple communication protocols, such as Profibus - DP, etc., enabling convenient communication and data interaction with other devices or control systems, and realizing the integration and networked control of the system. Isolation Characteristics: It usually has good electrical isolation performance, which can effectively isolate the electrical interference between the input signal and other parts of the system, improve the anti-interference ability of the system, and ensure the stability and accuracy of signal transmission. Flexible Configuration: Through software or hardware configuration, the type, range, filtering parameters, etc. of the input signal can be flexibly set to adapt to different application scenarios and user requirements. This flexibility enables the module to be widely applied in various complex industrial environments. Reliability Design: It adopts high-quality electronic components and advanced manufacturing processes, has high reliability and stability, can operate stably for a long time in harsh industrial environments, and reduce maintenance costs and downtime.

Application Scenarios Industrial Automation Control System: It is widely used in various industrial automation production lines, for collecting and processing various analog signals in the production process, such as real-time monitoring and control of parameters like temperature, pressure, and liquid level on the production line to ensure the stability of the production process and the consistency of product quality. Process Control Field: In process industries such as chemical, petroleum, and metallurgy, it is used for precise measurement and control of key process parameters. For example, in a chemical reaction kettle, by collecting analog signals such as temperature, pressure, and flow rate, precise control of the reaction process is achieved, ensuring the safety and high efficiency of the production process. Power System: In the power generation and distribution system, it can be used to monitor and collect various analog parameters, such as the voltage, current, and temperature of the generator, as well as the operating parameters of various power equipment in the substation, providing important data support for the stable operation and fault diagnosis of the power system. Building Automation System: In intelligent buildings, it is used to monitor and control analog parameters in systems such as air conditioning systems, water supply and drainage systems, and lighting systems. For example, by collecting indoor temperature and humidity signals, automatic control of the air conditioning system is achieved, providing a comfortable indoor environment and realizing energy-saving management at the same time.

Some Common Faults and Solutions of ABB CI873K01 3BSE058899R1 Module: 1. Power Supply Fault Fault Phenomenon: The module has no display, and all indicator lights are off. Possible Causes: Incorrect power supply wiring, abnormal power supply voltage, and internal power circuit failure of the module. Solutions: Check whether the power supply wiring is correct, and ensure that the power cord is firmly connected without looseness or open circuit. Use a multimeter to measure the power supply voltage and confirm whether it is within the specified working voltage range of the module (usually 24V DC±10%). If the voltage is abnormal, check whether the power supply is normal; if the voltage is normal, the internal power circuit of the module may be damaged, and professional maintenance personnel need to be contacted or the module needs to be replaced.

2. Communication Fault Fault Phenomenon: The module cannot communicate normally with the upper computer or other devices, and the communication indicator light flashes abnormally or is off. Possible Causes: Poor communication cable connection, incorrect communication parameter settings, damaged communication interface of the module, and electromagnetic interference. Solutions: Check whether the communication cable is firmly connected, and whether there is damage or open circuit. Confirm whether the communication parameter settings match those of other devices, including baud rate, data bits, stop bits, parity, etc. If the parameter settings are incorrect, reset the correct parameters. If the cable and parameters are normal, try replacing the communication cable to rule out the possibility of cable failure. If the problem still exists, the communication interface of the module may be damaged, and the module needs to be repaired or replaced. In addition, ensure that the installation position of the module is away from strong electromagnetic interference sources such as frequency converters and motors to prevent electromagnetic interference from affecting communication.

3. Abnormal Input Signal Fault Phenomenon: The module cannot collect input signals correctly, or the collected signals deviate greatly from the actual values. Possible Causes: Incorrect input signal wiring, sensor failure, damaged input channel of the module, and signal interference. Solutions: Check whether the input signal wiring is correct, and ensure that the signal wire is connected to the corresponding input channel and is firmly connected. Check whether the sensor connected to the module is working properly, and use tools such as a multimeter to detect the output signal of the sensor. If the sensor output is abnormal, replace the sensor. If the sensor is normal, try connecting other normal input signals to this channel to determine whether the input channel is damaged. If the channel is damaged, the module needs to be repaired or replaced. At the same time, take anti-interference measures, such as shielding the signal wire and reasonably wiring, to reduce signal interference.

4. Abnormal Output Signal Fault Phenomenon: The module cannot output correct control signals, or the output signals are unstable. Possible Causes: Incorrect output wiring, load failure, damaged output channel of the module, and incorrect configuration parameter settings. Solutions: Check whether the output signal wiring is correct and whether the connection is firm. Check whether the load device connected to the module output is working properly, and whether there are situations such as overload and short circuit. If the load device has problems, repair or replace the load. Confirm whether the output configuration parameters of the module are correct, such as output type, range, etc. If the parameter settings are incorrect, reset the correct parameters. If all of the above are normal, the output channel of the module may be damaged, and the module needs to be repaired or replaced.

5. Module Overheating Fault Phenomenon: The surface temperature of the module is too high, exceeding the normal working temperature range (generally 50℃ - 60℃). Possible Causes: Poor ventilation in the installation environment, excessive module load, and internal component failure. Solutions: Check whether the installation position of the module has good ventilation and whether there is enough space for heat dissipation. Ensure that when the module is installed in the control cabinet, the door of the control cabinet can be opened normally to ensure air circulation. Reduce the load of the module and avoid driving too many load devices at the same time. If the module operates under high load for a long time, it may cause overheating. If the above measures are ineffective, the internal components of the module may be faulty, and professional personnel need to be contacted for inspection and repair.

6. Abnormal Indicator Light Fault Phenomenon: The indicator lights on the module display abnormally, such as a certain indicator light being always on, always off, or flashing at an abnormal frequency. Possible Causes: Fault of the indicator light itself, internal logic error of the module, and failure of the relevant circuit. Solutions: If a certain indicator light is always on or always off, the indicator light itself may be damaged, and the indicator light can be tried to be replaced. However, the fault of the indicator light is usually caused by other problems, and the working status and relevant circuits of the module need to be further checked. If the indicator light flashes at an abnormal frequency, refer to the instructions about the status of the indicator light in the module manual to determine whether the module is in a certain special working state or has a fault. Conduct corresponding inspections and handling according to the prompts. If the cause cannot be determined, contact the technical support personnel of the manufacturer for help.