Description

Main Features

High-performance processing capability: Equipped with a powerful processor, it can quickly execute complex control algorithms and logical operations, and is able to process a large amount of input and output data in real time, meeting the high requirements for control accuracy and response speed in industrial production. For example, on a high-speed production line, it can rapidly process the signals transmitted by sensors and send out control instructions in a timely manner.

Flexible programming methods: It supports a variety of programming languages that comply with the IEC 61131-3 standard, such as Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), etc. Engineers can choose the appropriate programming language for program development according to their own habits and project requirements, and achieve various control functions conveniently and quickly.

Abundant communication interfaces: It usually has multiple communication interfaces such as Ethernet/IP, ControlNet, DeviceNet, etc., which is convenient for data communication and interaction with other devices (such as sensors, actuators, human-machine interfaces, upper computers, etc.), realizing the integration and expansion of the system, and enabling the easy construction of complex industrial automation networks.

High reliability and stability: Adopting industrial-grade design and manufacturing standards, it has good anti-interference ability and can operate stably in harsh industrial environments (such as high temperature, high humidity, strong electromagnetic interference, etc.). Some models also support redundancy functions, such as power redundancy, communication redundancy, etc., which further improves the reliability and availability of the system, reducing system downtime and maintenance costs.

Data storage and processing capability: It has a large memory space, which can store a large amount of information such as programs, data, and historical records. It supports the data recording function, which can record process data and event information, making it convenient for data analysis and troubleshooting, and helping to optimize the production process and improve the maintenance efficiency of equipment.

Easy integration and configuration: Through Rockwell's Studio 5000 programming software, the controller can be conveniently configured and programmed. The software provides an intuitive user interface and rich tools, which can quickly complete tasks such as project creation, device configuration, program writing, and debugging, reducing the difficulty and cost of system integration.

Technical Specifications for 1756-L84ES

| Ethernet performance | 10/100/1000 megabits per second |

| Built-in communication | 1 USB port (USB 2.0), embedded Ethernet port |

| Safety memory | 6 megabytes |

| Digital I/O / Analog I/O | 128,000 / 4000 max. |

| User memory | 20 megabytes |

| Supported number of programs per task | 1000 |

| Controller tasks | 31 standard tasks/1 safety task |

| Safety communication options (standard/safety) | EtherNet/IP, ControlNet, DeviceNet |

| Supported EtherNet/IP nodes | 250 nodes max. |

| Part Number | 1756-L84ES |

| Series | ControlLogix |

| Brand | Allen-Bradley |

| Current draw at 1.2 Volts DC | 5.0 milli Amps |

| Current draw at 5.1 Volts DC | 1.2 Amps |

| Weight | 0,39 kilograms (0.868 pounds) |

| Manufacturer | Rockwel Automation |

Technical Parameters Processor performance: The specific processor model and performance parameters vary depending on the product version, but it usually can provide a high computing speed and processing capability to meet the needs of industrial control. Memory capacity: Generally, it has a memory space ranging from several hundred megabytes to several gigabytes, which is used to store programs and data. You can select the appropriate model according to the project scale and requirements. Communication rate: The communication rate of the Ethernet/IP interface usually can reach 100Mbps or higher, enabling fast data transmission; other communication interfaces (such as ControlNet, DeviceNet) also have corresponding standard communication rates to ensure the communication efficiency of the system. Operating voltage: It usually uses a 24V DC power supply, and may also support other voltage ranges. Specifically, it shall be subject to the product specifications. Operating temperature range: Generally, it can work normally within the temperature range of 0°C to 55°C, and can adapt to the temperature changes in most industrial environments. Number of I/O points: It can be connected to multiple I/O modules, and the supported number of I/O points depends on the specific configuration, which can meet the input and output requirements of industrial projects of different scales.

Application Fields Manufacturing industry: In the automated production lines of the manufacturing industry such as automobile manufacturing, electronics manufacturing, and machining, it is used to control various production equipment (such as robots, numerically controlled machine tools, conveying equipment, etc.), realizing the automated control and coordinated operation of the production process, and improving production efficiency and product quality. Process industry: In the process industry fields such as chemical industry, petroleum, natural gas, and power, it can precisely control and monitor various parameters in the production process (such as temperature, pressure, flow rate, liquid level, etc.), ensuring the safe and stable operation of the production process, and realizing the optimization and energy saving of the production process. Energy management: In energy production and distribution systems (such as power plants, substations, smart grids, etc.), it is used to monitor and control the production, transmission, and consumption of energy, realizing the efficient utilization and optimized management of energy, and improving the reliability and stability of the energy system. Logistics and warehousing: In logistics and warehousing automation systems, it can control automated stereoscopic warehouses, automatic sorting systems, conveying equipment, etc., realizing the automation of goods storage, sorting, and transportation, and improving logistics efficiency and management level. Building automation: In the building automation systems of intelligent buildings, it is used to control equipment such as air conditioners, lighting, elevators, and security systems in buildings, realizing the intelligent management and control of buildings, and improving the comfort and energy efficiency of buildings.

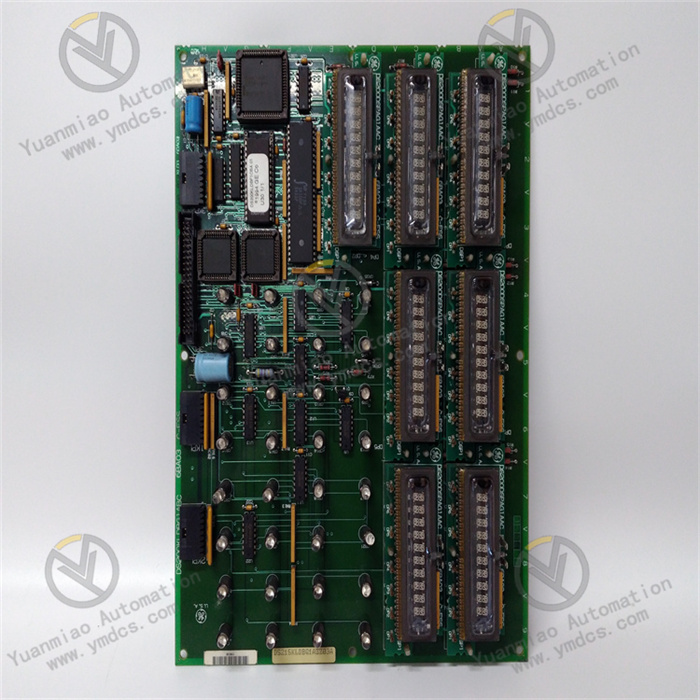

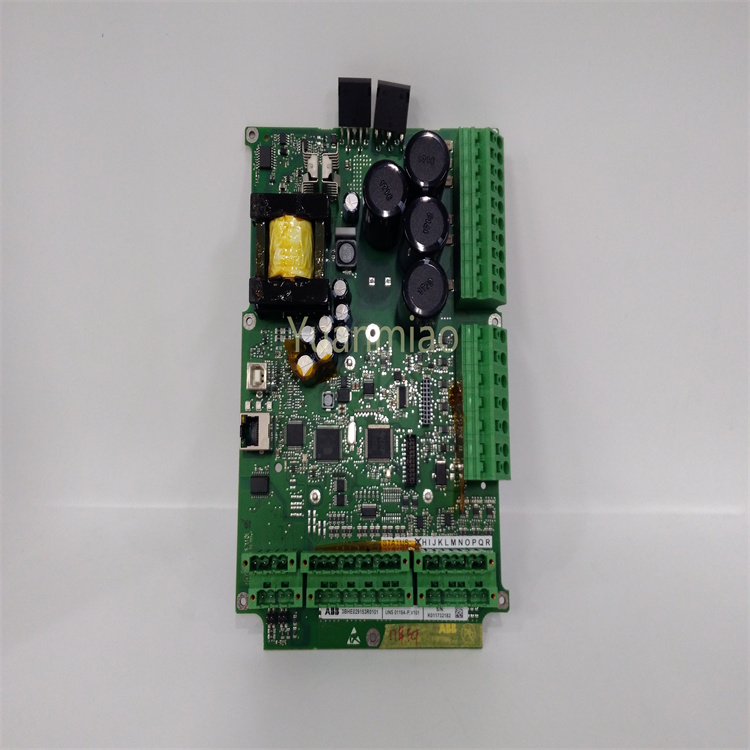

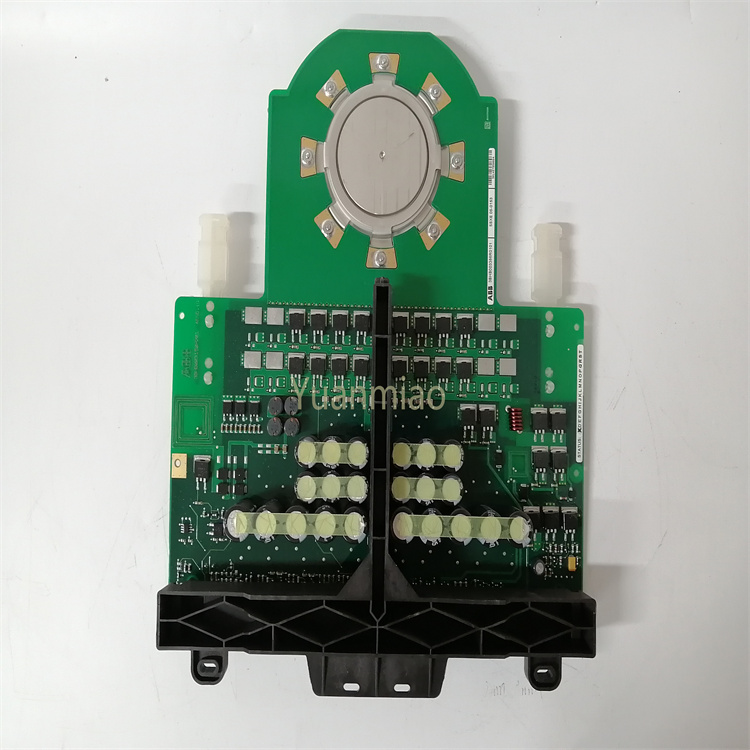

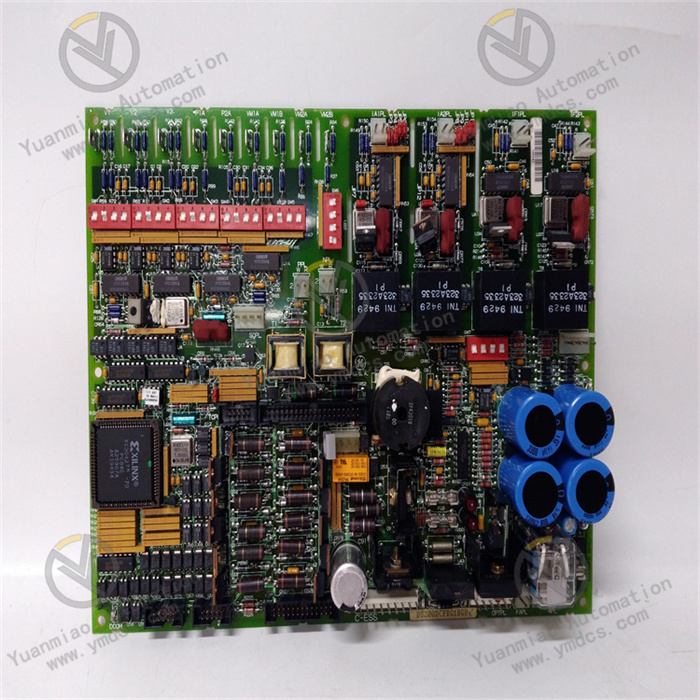

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.