Description

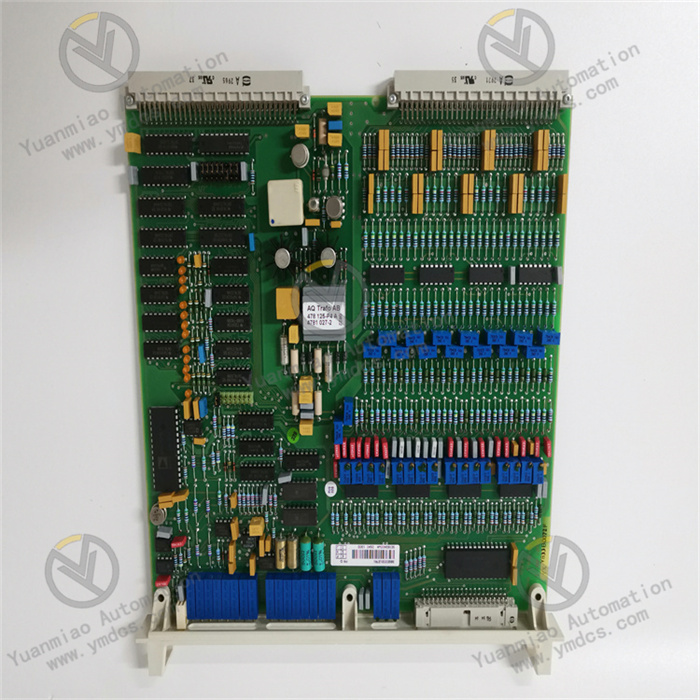

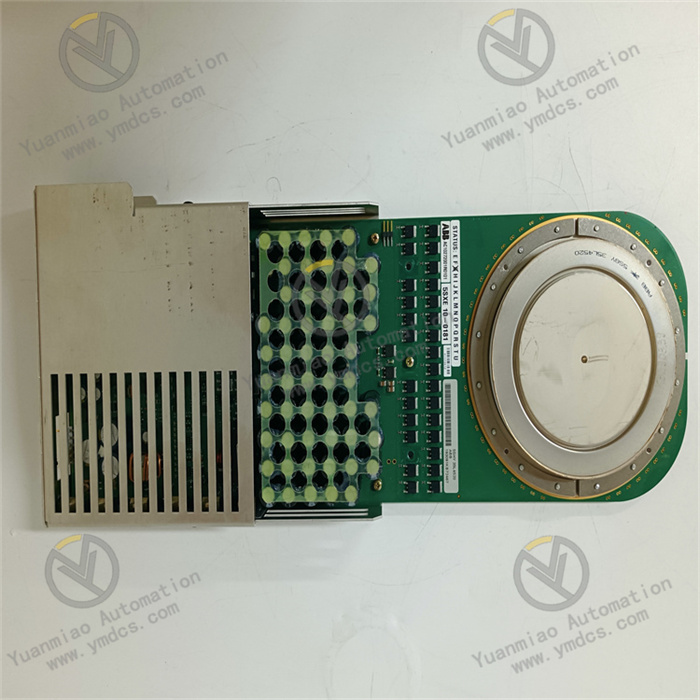

ABB GJR5253000R0160 07KT97

I. Basic Information

- Full Model: GJR5253000R0160 07KT97

- Series:

Belongs to ABB AC 800M controller series or S800 I/O system, serving as a core digital input/output (DI/DO) module in industrial automation, commonly used in distributed control systems (DCS). - Purpose:

As an interface between field devices and control systems, it realizes digital signal acquisition (DI) or control command output (DO), suitable for connecting switches, relays, sensors, solenoid valves, etc., supporting status monitoring and logical control in industrial automation.

II. Core Functions and Features

1. Signal Types and Channel Characteristics

- Digital Input (DI) Function (if the module is DI type):

Supports dry contact (passive) or wet contact (active) input to detect the on/off status of field devices (e.g., valve switching, motor start/stop signals).

Input response time ≤10ms to ensure real-time performance. - Digital Output (DO) Function (if the module is DO type):

Outputs 24V DC switching signals with a typical maximum load current of 2A per channel, supporting resistive (e.g., relays) or inductive (e.g., solenoid valves) loads.

Channel count is commonly 8 or 16 (refer to specific manuals, typically 16-way DO). - Isolation Design:

Electrical isolation voltage between channels ≥500V AC effectively prevents field interference from affecting system stability.

2. Status Indication and Reliability

- LED Indicators: Real-time display of power (POWER), operation (RUN), fault (FAULT), and channel status for on-site maintenance.

- Hot-Swap Support: Enables module replacement during system operation without affecting the overall control process.

- Diagnostic Function: Supports channel-level fault detection (e.g., short circuit, open circuit, overload) and reports alarms through the DCS.

III. Technical Parameters (Refer to Similar Products and ABB Standards)

| Parameter Dimension | Typical Indicators |

|---|---|

| Communication Protocol | Compatible with ABB AC 800M controllers, communicating via Profibus DP or EtherCAT. |

| Operating Voltage | DC 24V (±10%), power consumption ≤5W. |

| Input Specifications (DI) | Dry contact: ON (closed)/OFF (open) status detection, input impedance ≥10kΩ; response time ≤10ms. |

| Output Specifications (DO) | 24V DC/2A, supporting actuators like relays and solenoid valves, with overload/short-circuit protection. |

| Working Environment | Temperature: -20℃ ~ +60℃; humidity: 5%~95% (non-condensing). |

| Protection Level | Panel IP20 (requires installation in control cabinet), preventing dust and solid foreign objects. |

| Installation Method | DIN rail installation, compatible with ABB system racks, with adjacent module spacing ≥15mm for heat dissipation. |

IV. Application Scenarios

Process Industry Automation

- Chemical/Petrochemical: Connects pressure switches and level switches to monitor tank status and control pump/valve start/stop; drives solenoid valves via DO modules to switch process flows.

- Power System: Collects auxiliary contact signals (DI) of circuit breakers and contactors, remotely controls switching equipment (DO), supporting substation automation systems.

Discrete Manufacturing

- Metallurgical/Mechanical: DI modules read position signals from photoelectric sensors and limit switches, while DO modules control the start/stop of cylinders and motors to realize production line logical control.

Safety and Interlock Systems

- If the module has SIL certification (safety integrity level), it can be used in emergency shutdown systems (ESD), cutting off equipment power via DO output interlock signals under hazardous conditions.

V. Installation and Usage Key Points

1. Hardware Installation

- Fix in the control cabinet using DIN rail, ensuring good ventilation and avoiding high-temperature environments.

- Wiring Requirements:

- DI input: Dry contacts require external 24V DC power, while wet contacts directly connect to the signal source; use shielded twisted-pair cables with grounding resistance ≤1Ω.

- DO output: Load current must be lower than the per-channel rating (2A). Inductive loads need freewheeling diodes (e.g., IN4007) in parallel to prevent back EMF from damaging the module.

- Profibus bus connection requires terminal resistors (120Ω) to ensure stable communication.

2. Software Configuration

- Through ABB Control Builder M or 800xA Engineering software:

- Configure module address, communication protocol (e.g., Profibus slave address), and channel type (DI/DO).

- Define the mapping between input/output signals and controller variables (e.g., associate DI channel status with PLC register addresses).

3. Fault Troubleshooting

- If the "FAULT" light is on: Check for loose wiring, overloaded loads, or view channel fault codes (e.g., "channel short circuit", "power anomaly") via system diagnostic tools.

- In case of communication interruption: Confirm Profibus bus connection, module address conflicts, or whether bus load rate is too high (recommended ≤30%).

VI. Typical Supporting Equipment

- Controllers: ABB AC 800M CPU modules (e.g., PM866, PM891), 800xA system controllers.

- Field Devices:

- DI: Limit switches (e.g., OMRON WLCA12), proximity sensors (e.g., Turck NI15-U1), pressure switches (e.g., ABB PFTL101).

- DO: Relay modules (e.g., ABB RTU660), solenoid valves (e.g., ASCO 2-way valve), indicator lights.

- Communication and Auxiliary Modules:

ABB PFSA140 (Profibus adapter), PFSK151 (communication expansion module), PFSP101 power module.