Description

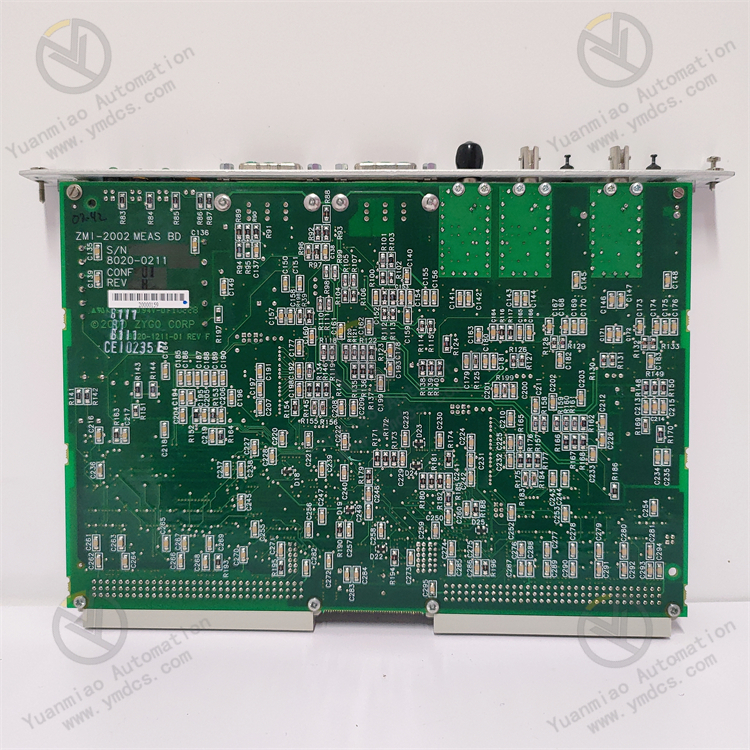

Zygo ZMI-2002 8020-0211

I. Overview

Zygo ZMI-2002 8020-0211 is a powerful dual-axis measurement board that plays an important role in high-precision measurement applications, especially in laser interferometer systems. As a leading enterprise in heterodyne displacement interferometry technology and application support, Zygo, relying on its profound technical accumulation and innovation capabilities, provides complete solutions for OEM metrology applications. Its products have been verified through years of practical application in cutting-edge production facilities and are highly recognized by the industry. ZMI-2002 8020-0211 is the crystallization of the company's excellent technology, dedicated to meeting the needs of various complex and high-precision measurement scenarios.

II. Technical Parameters

- Axis Configuration: This measurement board is designed with dual axes, which can accurately measure displacement or other physical quantities in two directions simultaneously. Compared with single-axis measurement boards, it greatly improves measurement efficiency and reduces the space and cost required for system integration. In some precision equipment that needs to synchronously monitor motion in two directions, such as the displacement monitoring of the workbench of high-precision lithography machines, its dual-axis measurement capability can provide more comprehensive and accurate data support.

- Data Transmission Rate: Through a standard hardware interface, it supports a P2 data transmission rate of up to 7.7 MHz. For multi-axis systems, it can be expanded to a maximum of 16 axes for data transmission at this rate simultaneously, and more axes can be easily expanded at the same rate. This high-speed data transmission capability ensures that measurement data can be collected and processed in a timely and rapid manner, meeting application scenarios with extremely high real-time requirements, such as rapid data feedback in high-speed dynamic measurement processes.

- Power Requirements: The power supply required for normal operation is +5V ± 5% with a current of 3.5A. This relatively stable and common power requirement facilitates integration and application in different power supply environments and reduces the difficulty of system construction caused by power adaptation issues.

- Measurement Accuracy: Based on Zygo's advanced heterodyne displacement interferometry technology, it has extremely high measurement accuracy, capable of precise measurement at the micrometer or even nanometer level. It meets the application needs of industries with nearly harsh precision requirements, such as semiconductor manufacturing and optical component processing, and plays a key role in scenarios such as measuring the surface flatness of computer disks and the processing dimensional accuracy of ultra-precision metal parts.

- Speed Format: The speed data output format adopts a 32-bit two's complement form. This format has good stability and compatibility in data processing and transmission, facilitating connection with various data acquisition systems and control systems, and ensuring that speed information can be accurately identified and processed.

III. Functional Features

- High-Precision Measurement Function: It adopts advanced interferometry technology to perform high-precision detection of physical quantities such as displacement, vibration, and morphology of the measured object. Its measurement accuracy can reach the nanometer level, providing reliable data support for ultra-precision manufacturing and inspection. In the semiconductor chip manufacturing process, it can accurately measure the micro-displacement during chip lithography, ensuring the accuracy and yield of chip manufacturing.

- Multi-Axis Coordinated Measurement: As a dual-axis measurement board, ZMI-2002 8020-0211 can simultaneously perform synchronous measurement and analysis of physical quantities in two axes. In some complex mechanical motion systems, it can simultaneously monitor displacement changes in the X and Y directions, and through comprehensive processing of multi-axis data, realize a comprehensive evaluation and precise control of the equipment's operating status.

- Programmable Characteristics: The measurement board can be fully programmed through an interface bus (VME or ISA) or a P2 interface. Users can flexibly set measurement parameters, data acquisition frequency, transmission methods, etc., according to specific measurement tasks and application scenarios, to achieve personalized measurement control schemes. For example, in measurement tasks with different precision requirements, users can adjust the measurement resolution and sampling frequency by themselves to balance the relationship between measurement accuracy and efficiency.

- High Stability and Anti-Interference Ability: Based on Zygo's mature technical system, this measurement board has a high degree of stability and can maintain stable measurement performance in complex industrial environments. It is insensitive to changes in signal amplitude, and even when the signal is subject to a certain degree of interference, it can accurately extract the measurement signal through advanced algorithms and circuit design, ensuring the accuracy and reliability of measurement results.

- System Expandability: Thanks to its simplified P2 interface design, single or multiple ZMI-2002 measurement boards can be easily connected to a single servo card or motor controller through a bus, facilitating system expansion. In large-scale measurement projects that require more measurement axes, the number of measurement boards can be easily increased to build a large-scale, multi-axis linked high-precision measurement system without the need for large-scale modification of the system architecture.

IV. Application Fields

- Semiconductor Manufacturing: In the semiconductor chip manufacturing process, from wafer processing, lithography to chip packaging, every link has extremely high requirements for precision. ZMI-2002 8020-0211 can be used to monitor the displacement accuracy of the lithography machine workbench, measure the flatness of the wafer surface, and achieve high-precision alignment in the chip packaging process, ensuring high quality and high yield of chip manufacturing, and providing key technical support for the development of the semiconductor industry.

- Optical Component Processing and Inspection: For the manufacturing of optical components such as optical lenses and reflectors, the flatness and curvature accuracy of their surfaces directly affect the performance of optical systems. This measurement board can accurately detect the surface morphology of optical components through laser interferometry technology, helping manufacturers timely discover defects and errors in the processing process, make targeted adjustments, and improve the processing quality of optical components. It is widely used in the production and manufacturing of optical products such as telescopes, microscopes, and high-end camera lenses.

- Precision Machinery Manufacturing: In the field of precision machinery such as precision machine tools and automated production lines, the motion accuracy of equipment directly determines product quality. ZMI-2002 8020-0211 can real-time monitor key parameters such as the displacement accuracy of the machine tool workbench and the straightness of the guide rail, providing data basis for equipment debugging, maintenance, and precision optimization, improving the accuracy and stability of precision machinery manufacturing, and meeting the strict requirements of industries such as aerospace and automobile parts manufacturing for precision machining.

- Metrological Research in Scientific Research Institutions: In the field of scientific research, especially in research projects involving ultra-precision measurement, such as the measurement of material microstructure and nanotechnology research, high-precision measurement equipment is needed to obtain accurate data. The high-precision measurement characteristics and programmable functions of Zygo ZMI-2002 8020-0211 can meet the diverse measurement needs of researchers, helping related scientific research projects to carry out in-depth and make breakthroughs.

- Laser Processing Systems: In laser processing processes such as laser cutting, laser welding, and laser drilling, it is necessary to accurately control the position and energy of the laser beam to ensure processing quality. ZMI-2002 can be used to monitor the displacement of moving parts of laser processing equipment, adjust the focusing position and processing path of the laser beam through feedback control, realize high-precision laser processing, and is widely used in laser processing links in industries such as electronic manufacturing and medical device manufacturing.

V. Common Faults and Solutions

- Abnormal Measurement Data:

- Fault Phenomenon: The measured data has deviations, jumps, or is unstable, inconsistent with the actual state of the measured object.

- Possible Causes: The laser interference optical path is disturbed, such as the presence of strong electromagnetic fields or vibration sources around affecting the stability of the optical path; the sensor components of the measurement board are faulty, resulting in inaccurate signal collection; the data transmission line has poor contact or interference, affecting the integrity of data transmission.

- Solutions: Check the environment around the laser interference optical path, eliminate strong electromagnetic field sources, and perform effective vibration isolation treatment on the measurement equipment, such as installing shock pads and using vibration isolation platforms, to ensure the stability of the optical path; use professional detection tools to detect the sensors of the measurement board, and if a faulty sensor is found, contact Zygo manufacturer in time to replace it with a sensor of the same model; carefully check the data transmission line for looseness, damage, etc., repair or replace the transmission line if there is a problem, and take shielding measures for the transmission line to reduce external interference.

- Inability to Communicate with External Devices:

- Fault Phenomenon: The measurement board cannot establish a communication connection with external devices such as servo cards, motor controllers, or upper computers, or data loss and errors occur frequently during communication.

- Possible Causes: Incorrect communication interface settings, such as baud rate, data bits, stop bits and other parameter configurations do not match with external devices; damage to the communication interface hardware, such as burned interface chips, broken interface pins, etc.; incompatible communication protocols, if non-standard communication protocols are used, there may be conflicts with the protocols of external devices.

- Solutions: Carefully check the communication interface setting parameters of the measurement board and external devices to ensure they are consistent. You can refer to the device manual or contact the manufacturer's technical support for correct settings; use tools such as a multimeter to detect the communication interface hardware, and if hardware damage is found, contact Zygo after-sales service for repair or replacement of the interface hardware; if it is a communication protocol problem, try to use standard communication protocols such as Modbus and Profibus for connection. If a specific protocol must be used, communicate with the equipment supplier to negotiate a solution to the protocol compatibility problem, or develop communication conversion software to achieve protocol conversion.

- Overheating of the Measurement Board:

- Fault Phenomenon: The temperature of the measurement board is too high after running for a period of time, which may trigger the overheating protection mechanism, resulting in reduced equipment performance or even shutdown.

- Possible Causes: Poor heat dissipation design of the measurement board, such as too small heat sink area, faulty cooling fan, etc., leading to ineffective heat dissipation; long-term high-load operation, too frequent measurement tasks, resulting in excessive power consumption of the measurement board and excessive heat generation; the working environment temperature of the equipment is too high, exceeding the normal working temperature range of the measurement board, affecting the heat dissipation effect.

- Solutions: Check whether the heat sink of the measurement board is firmly installed and whether the cooling fan is running normally. If the fan is faulty, replace it in time; reasonably arrange measurement tasks to avoid long-term continuous high-load operation of the measurement board, and set appropriate measurement intervals; improve the working environment of the equipment, strengthen ventilation and heat dissipation, such as installing air conditioning equipment to control the ambient temperature within the normal working temperature range of the measurement board. If the ambient temperature cannot be changed, consider adding additional heat dissipation devices to the measurement board, such as forced air-cooled radiators.

- Program Failure to Run Normally or Setting Parameters Invalid:

- Fault Phenomenon: After the user programs and sets the measurement board, the program cannot run as expected, or the set parameters do not take effect in the actual measurement process.

- Possible Causes: The programming software version is too low and incompatible with the current firmware of the measurement board, resulting in abnormal program operation; improper operation when setting parameters, such as incorrect parameter input, failure to save settings correctly, etc.; failure of the internal storage chip of the measurement board, resulting in inability to correctly store and read the set parameters.

- Solutions: Go to the official Zygo website, download the latest version of the programming software, and install the upgrade according to the instructions to ensure the compatibility between the software and the measurement board firmware; carefully check the parameter setting process, confirm that the parameter input is correct, and save the settings according to the correct steps; if the storage chip is suspected to be faulty, contact Zygo professional technicians to use professional equipment to detect and repair the internal storage chip of the measurement board. If it cannot be repaired, replace the storage chip and reconfigure the parameters and debug the program.