Description

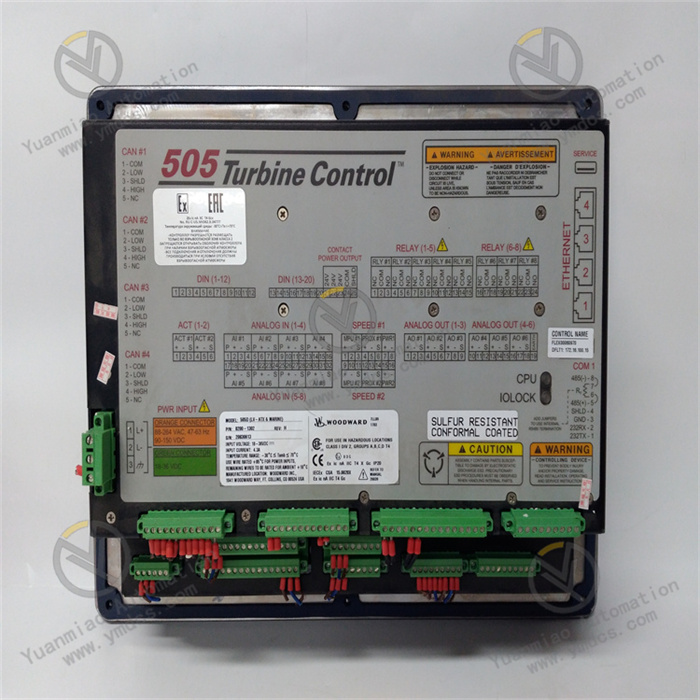

The WOODWARD 8200-1312 is a product manufactured by Woodward (WOODWARD) that is widely used in the field of industrial control. It is often related to the control of power equipment such as engines and turbines. Specification Parameters Power Input: It usually supports a variety of power input voltage ranges. Commonly, it is 24VDC, and a certain voltage fluctuation range (such as ±10%) is allowed to adapt to different power supply environments. Operating Temperature: Generally, it can work normally within the temperature range of -40°C to +70°C to meet the requirements of different industrial environments. Storage Temperature: -40°C to +85°C. Communication Interfaces: It may be equipped with various communication interfaces, such as RS-485, Ethernet interfaces, etc., for data transmission and communication with other devices. Communication parameters such as the baud rate can be configured according to actual applications. Input and Output Channels: It has multiple analog input channels (for example, 8 or more) to receive signals from various sensors, such as temperature, pressure, rotational speed, etc.; at the same time, it is equipped with a certain number of analog output channels (such as 4 or more) that can output control signals to adjust the actuators. In addition, there may also be digital input and output channels for processing on-off signals.

Product Features High-precision Control: It can accurately regulate and control the operating parameters of power equipment to ensure that the equipment can operate stably and efficiently under various working conditions. For example, it can precisely control the fuel injection quantity of the engine to achieve the best combustion efficiency and performance. Flexible Programming Ability: It supports users to program and configure according to specific application requirements. Through dedicated programming software, users can set control logic, parameter alarm values, etc., to make the equipment adapt to different working scenarios. High Reliability: It adopts high-quality electronic components and a robust housing design, has good anti-interference ability, and can operate reliably in harsh industrial environments. For example, it can resist electromagnetic interference, vibration, and shock, etc. Data Recording and Diagnostic Functions: It can record the operating data of the equipment, such as historical parameters, fault information, etc., to facilitate users to conduct data analysis and fault diagnosis. Through the analysis of these data, potential problems can be discovered in advance, maintenance measures can be taken in a timely manner, and the equipment downtime can be reduced.

Common Faults and Solutions Communication Fault Fault Manifestation: Unable to establish a communication connection with other devices, or data loss or errors occur during the communication process. Solutions: Check whether the communication cable is firmly connected, and whether there is any damage or open circuit; Confirm whether the parameter settings of the communication interface (such as baud rate, data bits, stop bits, etc.) match those of other devices; If it is network communication, check whether the network equipment (such as routers, switches) is working properly. Abnormal Input Signals Fault Manifestation: The analog or digital input signals are inaccurate, or the input signals cannot be detected. Solutions: Check whether the sensor is working properly, which can be judged by measuring the output signal of the sensor; Check whether the wiring of the input channel is correct, and whether there is any looseness or short circuit; If the input channel is damaged, it may be necessary to replace the module or carry out maintenance.

Abnormal Output Control

Fault Manifestation: The analog or digital output signals cannot achieve the expected control effect, or the output signals are unstable.

Solutions: Check whether the actuators are working properly, such as valves, motors, etc.; Check whether the wiring of the output channel is correct, and whether there is any looseness or short circuit; If the output channel is damaged, it may be necessary to replace the module or carry out maintenance; Adjust the control parameters to ensure that the output signals meet the actual requirements.

Power Supply Fault

Fault Manifestation: The module cannot be powered on normally, or it suddenly loses power during operation.

Solutions: Check whether the input power supply voltage is within the specified range, and whether the power supply line is well connected; Check whether the power supply module is damaged, and if necessary, replace the power supply module.

WOODWARD Related Products

| WOODWARD 5464-334 | WOODWARD 5464-550 |

| WOODWARD 5464-335 | WOODWARD 5464-554 |

| WOODWARD 5464-337 | WOODWARD 5464-555 |

| WOODWARD 5464-768 | WOODWARD 5464-596 |

| WOODWARD 5464-827 | WOODWARD 5464-643 |

| WOODWARD 5464-828 | WOODWARD 5464-645 |

| WOODWARD 5464-829 | WOODWARD 5464-646 |

| WOODWARD 5464-830 | WOODWARD 5464-647 |

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.